Clean tool holders significantly contribute to precision in machining. Therefore, it is surprising that fixtures are still frequently manually cleaned before the tools get replaced, because this process does not ensure that swarf and residues from processing media get removed reliably. Another disadvantage is the high demand on personnel and time caused by each manual process. Additionally, cleaning is usually performed with costly compressed air or brushes and a low flashpoint solvent such as benzine, although virtually every company that manufactures machined parts is equipped with a cleaning machine.

Special inserts enable easy automated cleaning

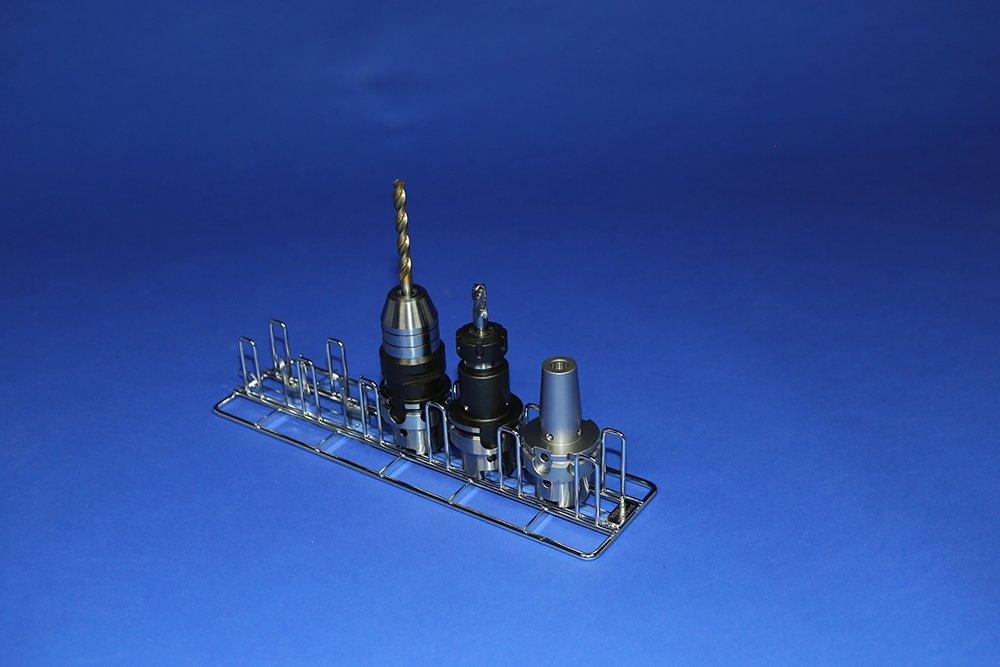

In order to be able to clean the equipped tool holders also in the cleaning machine, Metallform has developed specific inserts for standard cleaning baskets such as the MEFO-BOX. The inserts are available for different tool fixtures, e.g. HSK, Conus, VDI and SBA and can be adapted to the type and size of the holders. Fixation of the holder in the insert only takes place at uncritical areas.

Adapted to the size of the working chamber of the cleaning machine, the equipped tool fixtures can be placed vertically or horizontally – e.g. for deep-hole drills – in the insert. This also allows for placing the tool holder directly at the machine or machining centre into the insert and for transporting it safely to the cleaning machine. For cleaning, various and even different inserts can be placed in a MEFO-BOX or standard cleaning basket.

On the one hand, this makes the cleaning of tool holders faster and more process reliable. This is especially due to the open design of the inserts which allows the cleaning medium and mechanics, e. g. ultrasonic waves or spray jet, to reach the tool holders freely from all sides. In order to improve the cleaning effect, the basket can be swivelled in the machine. On the other hand, automated cleaning increases efficiency. Staff that had been cleaning the tool holders manually can now spend their time with more productive work.

After cleaning and replacing tools the holders can be transported back to the metal cutting machine safely and without damages.

Carefully processed stainless steel

Like all cleaning baskets from Metallform, the inserts are made of stainless steel with an electrolytic polished surface. This high-quality material can be used with all cleaning media and ensures a long service life. The outer structure’s rods are butt welded to avoid corners posing the risk of injury.

METALLFORM Wächter GmbH is an owner-run company active in the fields of sheet metal working and wire processing.

In the wire processing division, Metallform develops and manufactures cleaning baskets and workpiece holders from stainless steel wire. These products are used in the automotive and automotive supply industry, mechanical engineering, machine building, aerospace, optics, precision mechanics, electrical and electronics industry, medical and laboratory applications, and many other sectors. Comprehensive experience in the cleaning sector and intensive cooperation with notable manufacturers of cleaning machines form the solid foundation for the services. To be able to provide the optimum solution for any task, alongside its specialist consulting service with the MEFO-BOX and MEFO-VARIO system Metallform offers a comprehensive standard range of products off-the-shelf in the standard sizes of cleaning machine manufacturers as well as customised solutions for part-specific workpiece holders.

In the sheet metal working division, Metallform manufactures stainless steel components such as laser-cut parts, bent components and welded parts as well as complex assemblies. Metallform employs 70 employees and generated a turnover of around 8 million Euros in 2016.

Thank you in advance for sending a specimen copy and publication link.

Contact for Press:

SCHULZ. PRESSE. TEXT., Doris Schulz, Landhausstr. 12,

70825 Korntal, Germany, Phone +49 (0)711 854085

Fax +49 (0)711 815895, ds@pressetextschulz.de, www.schulzpressetext.de

METALLFORM Wächter GmbH, Anja Wächter, Gewerbestr. 35,

75015 Bretten, Germany, Phone +49 (0)7252 9426-10

anja.waechter@metallform.de, www.metallform.de

METALLFORM Wächter GmbH

Gewerbestraße 60

75015 Bretten-Gölshausen

Telefon: +49 (7252) 94260

Telefax: +49 (7252) 942611

http://www.metallform.de

Journalistin (DJV) und Texterin

Telefon: +49 (711) 854085

Fax: +49 (711) 815895

E-Mail: doris.schulz@pressetextschulz.de

![]()