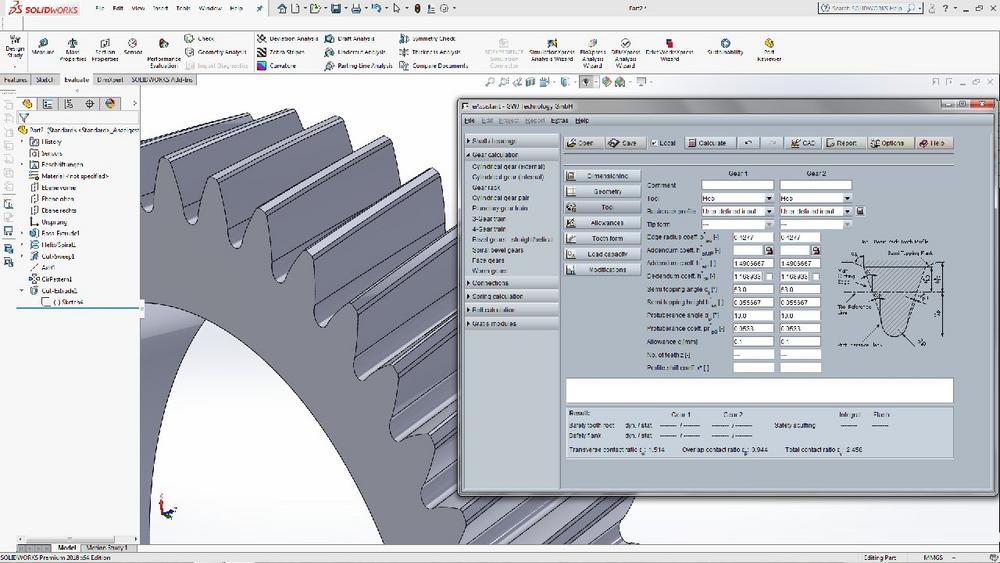

The latest software release introduces multiple enhancements making the life of engineers easier than ever before. One example is the new menu item "New". Clicking the menu item "New" closes the current calculation and opens the calculation module with the internal eAssistant default setting or the user´s own default file.

The calculation modules for single cylindrical gears (external/internal), three- and four-gear train systems and gear racks now include DIN 58405 for fine mechanics, ISO 1328 and ANSI/AGMA 2015 in addition to DIN 3961 for gear tolerances/gear qualities.

The definition of the basic rack profiles for the cylindrical gear pair and the single cylindrical gear (external) was supplemented by the semi topping flank and topping. Using the definition of the semi topping flank, the corresponding hobs can then be specified, and

they generate an addendum chamfer during the cutting process.

The option "Topping" allows to define the tip diameter directly with the dedendum coefficient of the tool, making it impossible to subsequently modifiying the tip diameter. The result, at the same time, will be tip diameter allowances analogous to the root diameter allowances directly from the tooth thickness allowances.

The eAssistant 3D CAD plugins for various CAD systems support the new function and the semi topping flank can be considered in the 3D CAD model.

Visit www.gwj.de for more information or contact GWJ at +49 (0)

531 1293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology, a leading engineering company with its headquarter in Braunschweig, Germany, stands for high quality products and innovative software development. With keen insight, high energy and an enthusiastic team of engineers, we put our utmost efforts, skills, knowledge and passion into our work to achieve top quality products.

Our portfolio includes the development of standard calculation software for machine elements, such as shafts, rolling bearings, cylindrical gears, bevel gears, etc. To increase the efficiency in the design process and to combine calculation and CAD, we provide CAD plugins for various 3D CAD systems.

Our software solutions are designed with a sleek user interface, making it easier than ever to design or re-calculate machine elements.

Additionally, we have geared our company to offer a special software application for the determination of real 3D tooth form geometries of complex gears. The tooth form is the basis for a 3D model to manufacture gears in conjunction with multi-axis machining centers. The software opens completely new possibilities for engineering.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de