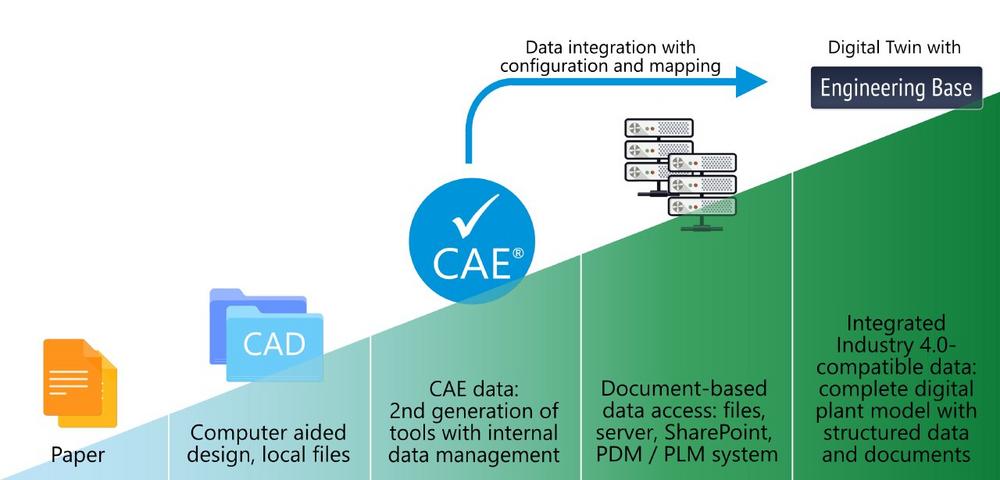

Legacy data is configured, mapped and imported in common formats such as XLS or DWG by the collaborative platform Engineering Base (EB). Thus the system consolidates all information about a particular object from different disciplines into a central object model – together with related attributes and representations in various documents. All imported objects, from the pump in the P&ID to the final terminal in the cabinet diagram, then form an overall plant model with intelligent links. It is consistently and clearly stored in the database that can be used by all engineering disciplines involved.

Much more than PDFs & other documents

This is the only way to implement "real" digitization. Although PDFs, DWG graphics, and scans are digital documents, they are sheet-oriented and do not have a referencing data model. Their content thus cannot be used in the IoT sense. A navigation system, for example, cannot do anything with a simple digital street map because it can extract neither one-way streets nor traffic congestion information and the like. PDFs & other documents equally impede plant engineers: the objects in documents cannot be independently accessed and edited. Thus far, it has been necessary to take a detour via the diagrams, lists and databases of the individual disciplines. In this way, change management always remains a bottleneck prior to more efficiency. EB, on the other hand, contains a common, corresponding data model for everyone involved, which keeps each individual piece of information consistent and available at all times. It can also be accessed online and from the Cloud due to EB’s three-layer architecture.

Fit for Industry 4.0

This means that plant operators, who now usually have to manage their documentation in many different, inconsistent sources, will be fit for modern and future-oriented maintenance. After model-based digitization, revampings and expansions in particular can be performed far quicker and more consistently with significantly less effort. Downtimes are significantly reduced.

A leading and globally acting chemical plant operator has already successfully deployed the migration solution. The company successfully transferred for one of its plants around 700 P&IDs and several thousand electrical graphics to EB. For revamping projects, the EPC responsible can now work directly on the engineering data, consistently and without a time-consuming back-and-forth process.

Aucotec AG has over 30 years of experience in developing engineering software for the entire lifecycle of machines, plants and mobile systems. The solutions range from flow diagrams via control and electrical engineering for large-scale plants to modular harness design in the automotive industry. Aucotec software is in use all over the world. In addition to its headquarters in Hanover, Aucotec operates six further sites in Germany as well as subsidiaries in China, South Korea, France, the United Kingdom, Italy, Austria, Poland, Sweden and the US. A global network of partners ensures local support throughout the world.

AUCOTEC AG – EN

Hannoversche Straße 105

30916 Isernhagen

Telefon: +49 (511) 6103-0

Telefax: +49 (511) 614074

http://www.aucotec.com

Presseansprechpartner

Telefon: +49 (511) 6103-186

Fax: +49 (511) 614074

E-Mail: jki@aucotec.com

![]()