MES HYDRA offers two new products to handle large amounts of data much easier and more flexible than with conventional methods. The new products can be used in combination and also inde-pendently:

Edge Computing Suite

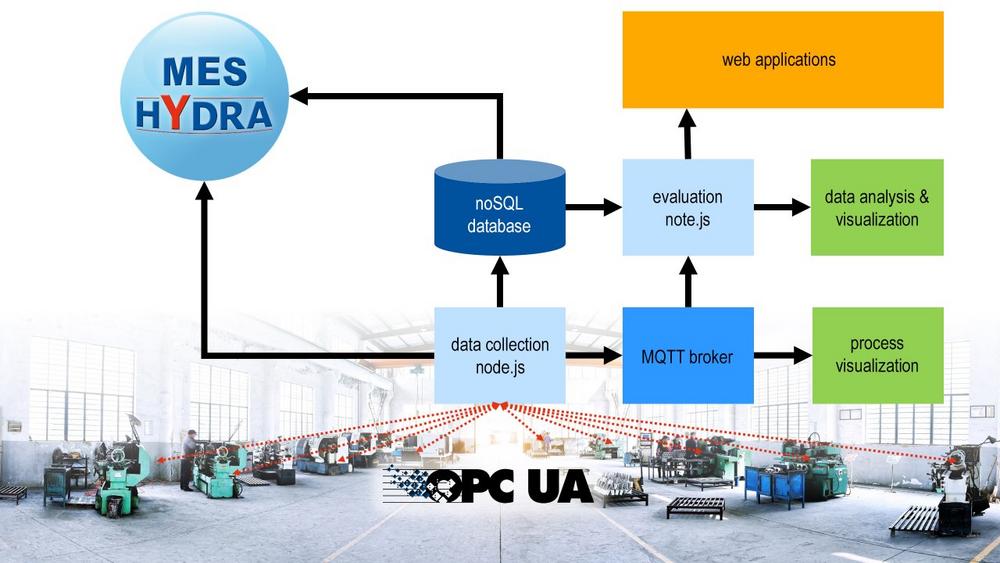

EdgeCS (Edge Computing Suite), the new collection infrastructure for mass data decouples the cap-ture from the processing of the data. This allows large amounts of data to be collected and stored at a high speed – and that is what many people understand by Big Data in the shop floor. EdgeCS uses state-of-the-art technologies, such as OPC UA, Node.js (www.nodejs.org), noSQL databases, as well as the streamlined messaging protocol MQTT (www.mqtt.org) to provide effective data capture. The data is passed directly to process visualization via an MQTT broker. Consequently, EdgeCS can be used as a stand-alone tool.

Real-time Process Data Monitoring

Process parameters can be visualized directly on the machine or on the office PC with the newly de-signed graphical elements of the Real-Time Process Data Monitoring. Thus, both operators at the ma-chine and office staff are informed about the current status of specific machines or processes and can react quickly to deviations if required. Real-time Process Data Monitoring is based on communication via MQTT, which uses very few IT resources thanks to the simple Publish-Subscribe Procedure. In sum, individual customer requirements can be easily implemented.

Product availability

Both Edge Computing Suite and Real-time Process Data Monitoring from the HYDRA product group Process Data (PDV) are already available.

You will find further information under mpdv.info/pmpdven

Manufacturing Execution Systems (MES) support production companies to improve efficiencies in their production processes, increase productivity and thus to secure or enhance their ability to com-pete. A state-of-the-art MES puts companies in the position to record and evaluate data along the complete value-added chain in real-time. People in charge can therefore react instantly to unforeseen events in the daily production routine and put in suitable measures. The MES supports on all levels short-term and far-reaching decisions by providing a reliable data basis.

HYDRA, the modular structured MES by MPDV, features an extensive functional range and meets all requirements stated in the VDI guideline 5600. Individual HYDRA applications based on a central MES database can be combined without the use of interfaces. Thus, HYDRA guarantees a 360-degree view on all resources in production and can incorporate overlapping processes. Powerful tools for con-figuration and customization ensure that HYDRA can be modified in order to cater for company and industry specific requirements. HYDRA can be integrated into existing IT landscapes and is used as a link between production (shop floor) and the management level (e.g. ERP system). Production compa-nies are particular reactive using an MES system like HYDRA and therefore remain competitive – es-pecially looking at Industry 4.0.

MPDV Mikrolab GmbH (www.mpdv.com) headquartered in Mosbach/Germany is developing Manu-facturing Execution Systems (MES) and is looking back on over 40 years project experience in the production environment. MPDV’s product portfolio comprises of MES products, services for the MES environment and entire MES solutions. MPDV currently employs more than 380 people across ten sites in Germany, Switzerland, Singapore, China and USA. Customers from different industry sectors, ranging from metal processing to medical engineering, benefit from more than 1.000 installations of MPDV’s MES solutions. These include medium-sized companies to global enterprises. Being part of the TOP 100 businesses MPDV is one of the most innovative medium-sized companies in Germany.

MPDV Mikrolab GmbH

Römerring 1

74821 Mosbach

Telefon: +49 (6261) 9209-0

Telefax: +49 (6261) 18139

http://www.mpdv.com

Marketing Manager

Telefon: +49 (6202) 9335-0

E-Mail: n.neubig@mpdv.com

![]()