The surface finish of blisks (“Blade Integrated Disks”) in airplane and other turbines affects to a large extent the airflow characteristics and, thus, the overall efficiency, fuel consumption and noise emissions.

To date the surface finishing of blisks was done manually with grinding disks and other manually operated tools. Due to the “human factor” the quality of the final finish could greatly vary between work pieces. Frequently, it could even happen that certain surface areas were not finished at all.

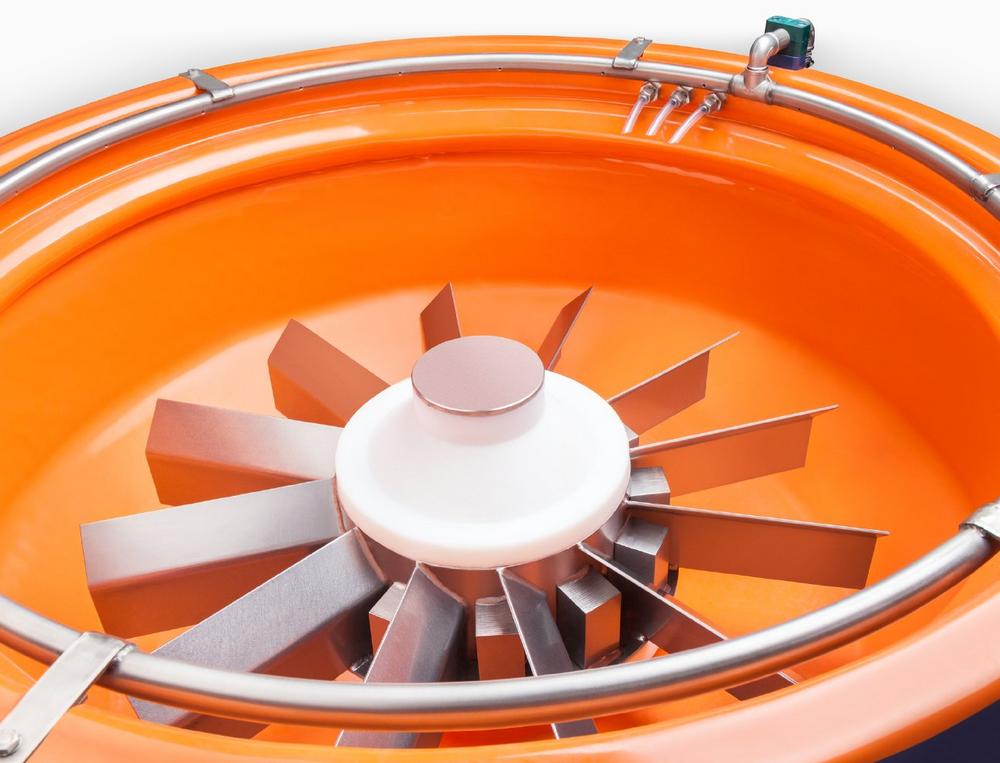

For the consistent and high quality finishing of circular high value components Walther Trowal redesigned the rotary vibrator “CM” in close cooperation with leading turbine manufacturers to make it more suitable for treating all kinds of turbine components.

The “CM” system allows deburring and general surface improvement of components with diameters of up to 980 mm.

Single work pieces are mounted to the inner dome of the processing bowl. The height of the inner dome itself has been drastically shortened. After grinding media has been filled into the bowl, a vibratory motor causes the complete work bowl to vibrate. This causes a constant “rubbing” of the media against the fixed work piece. Since the “rubbing” action is highly homogeneous, a uniform, even finish on all surface areas of the disk and blades is achieved. After completion of the process the surface roughness readings amount to Ra = 0.2 to 0.4 µm.

Starting with an initial surface roughness of Ra = 4 to 5 µm, the desired finishing results are achieved within about five to six hours. Compared to this innovative method the manual finishing of blisks can take several days.

Christoph Cruse, sales manager at Walther Trowal, is commenting on the special conditions prevailing in the aerospace industry: “Especially for the production of turbine components any manual manufacturing operations must be viewed with great skepticism, because the quality of the work will vary greatly. With our new finishing machine we have completely eliminated the vagaries of the human factor. And, we can reduce the finishing times for blisks from several days to just a few hours”.

For finishing of blisks Walther Trowal is recommending the special finishing media, type V 2030. This media produces very smooth surface finishes on materials and shapes, which are typical for blisks. Of course, the V 2030 media is globally approved for the aerospace industry.

For 85 years Walther Trowal has been a pioneer and market leader in various surface treatment technologies. The company offers modular and custom engineered solutions for a wide range of surface treatment problems.

Initially only making vibratory finishing equipment, over the years Walther Trowal has continuously broadened its product range and today offers a wide portfolio of equipment and services for improving all kinds of surfaces, e.g. mass finishing, part cleaning, shot blasting and drying of a wide spectrum of work pieces, last but not least, the coating of mass produced small parts.

Walther Trowal offers not only various types of equipment but complete surface treatment systems: By linking the various equipment modules and automating the complete process, we are able to precisely adapt our process technologies to the technical requirements of our customers. This also includes various types of peripheral equipment and process water cleaning and recycling systems. Of course, we also offer comprehensive pre- and after-sale service like sample processing in one of our demonstration labs and global repair and maintenance service.

Walther Trowal serves many customers in many industries around the world. For example, in the automotive and aerospace industry, medical engineering and wind power generation.

Walther Trowal GmbH & Co. KG

Rheinische Str. 35-37

42781 Haan

Telefon: +49 (2129) 5710

Telefax: +49 (2129) 571225

http://www.walther-trowal.de/

Telefon: +49 (2129) 571-455

Fax: +49 (2129) 571-225

E-Mail: m.huebner@walther-trowal.de

V.I.P. Kommunikation

Telefon: +49 (241) 89468-55

Fax: +49 (241) 89468-44

E-Mail: stein@vip-kommunikation.de