The costs for refrigerants with high global warming potential (GWP) are rising around the world. As a driver of innovation in the refrigeration and air-conditioning industry, BITZER has been offering climate-friendly, energy-efficient CO2 solutions for a whole host of applications for more than 20 years. These are ideal for a populous country like India, where around 40 per cent of food spoils due to a lack of refrigeration – and where energy is in short supply, but the transition to sustainable, intelligent technologies is a high priority due to the significant environmental impact.

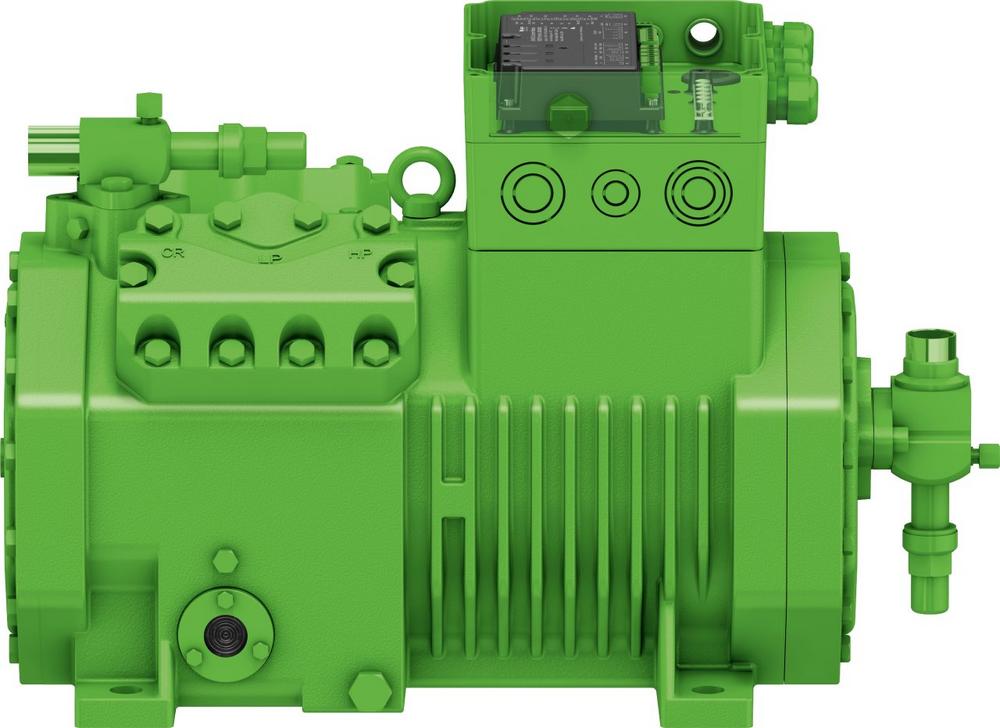

Efficient progress: ECOLINE reciprocating compressors with IQ module

ECOLINE reciprocating compressors offer maximum energy efficiency in full and part-load and are designed for a very extensive range of applications in supermarkets and beyond. The exhibit at ACREX India has a displacement of up to 41 m3/h (50 Hz). One of the series’ benefits: it offers maximum freedom in the selection of the refrigerant. Whether new climate-friendly refrigerants such as R1234yf, R1234ze(E), low-GWP blends or natural refrigerants, users will always find a suitable, eco-friendly solution in ECOLINE. Thanks to the intelligent IQ module, BITZER ECOLINE reciprocating compressors represent a milestone in terms of energy efficiency. In combination with the VARISTEP mechanical capacity control users are able to infinitely adjust compressor capacity between 10 and 100 per cent – a true alternative to frequency inverters. The IQ module monitors the system independently and sends out a warning if the specified applications limits are exceeded. It improves the efficiency of the entire system and expands the compressor’s potential applications, whilst simplifying operation, installation and maintenance.

‘CO2 is one of the refrigerants of the future. With the ECOLINE series, we make efficient CO2 technology simpler and easier to understand,’ explains Rainer Große-Kracht, Chief Technology Officer at BITZER. ‘With its global warming potential (GWP) of 1, CO2 is climate-neutral and therefore offers users planning security over the long term.’

Flexible and eco-friendly: OS.A95 screw compressors for ammonia solutions

With its energy-efficient OS.A95 screw compressor series, BITZER offers a climate-friendly and powerful solution for ammonia applications. The natural refrigerant has no global warming potential (GWP = 0) and doesn’t damage the ozone layer. Their cooling capacity and automatic Vi adjustment make OS.A95 screw compressors suitable for a whole host of applications. In combination with automatic Vi adjustment, the series’ extensive application limits diagram enables efficient use of the series in air-conditioning, medium and low temperature systems as well as in heat pump applications. The optimised rotor profiles, the high internal tightness and the large flow cross sections in the compressor also contribute to efficient operation. Typical applications of the OS.A95 screw compressors include medium and low temperature refrigerated distribution warehouses, shock freezers and process liquid chillers. The series offers a large capacity range with a displacement of up to 1,015 m3/h at 2,900 rpm per compressor, as well as the option of parallel connection for expanding system capacity. A key component of the OS.A95 series is the integrated double slider, which can be used to infinitely adjust the compressor’s cooling capacity and internal volume ratio within a wide application range for greater efficiency. The integrated BITZER IQ module enables precise, stepless compressor control in accordance with the requirements of the superior system controller, and ensures high operating reliability through the continuous, automated monitoring of application limits as well as through integrated three-stage warning and alarm management.

Intelligent compact screw compressors: the CSVH3 series

The intelligent, speed controlled CSVH3 series is a unique innovation in the field of compact screw compressors. The particularly powerful inverter-driven compressors have a displacement of up to 1,156 m3/h (50 Hz) and are optimised for air-cooled liquid chillers and heat pumps. Thanks to an integrated frequency inverter, they simplify to a high degree the installation and safe use of speed controlled compressors in air-conditioning, process cooling and heat pump applications. The series operates with a wide range of control, is ideal for systems with high part-load and meets the most stringent requirements in terms of seasonal efficiency.

A strong team – ORBIT 6 and 8 scroll compressors

The proven ORBIT 6 and 8 scroll compressors are designed for air-conditioning systems and heat pumps. They’re extremely compact and boast low energy consumption, low noise operation and a variable speed range (ORBIT 6: 40 to 75 Hz, ORBIT 8: 35 to 75 Hz). Even when it comes to displacement, the two series offer exceptional flexibility with capacities of 20 and 77 m3/h at 50 Hz. And in conjunction with the integrated variable speed drive (VSD), the extended frequency ranges offer major benefits: users can precisely tailor the speed and cooling capacity of ORBIT scroll compressors to match actual load requirements for outstanding energy efficiency in both part-load and full-load operation. This leads to especially high EER, ESEER/IPLV and SCOP values and lowers operating costs. Thanks to their high evaporation temperature limits, the compressors are also suitable for large data centres. They can be combined very easily with the proven BITZER Advanced Header Technology (BAHT) to form tandem units. ‘BAHT even works with different capacities and without active oil equalisation – in many cases even if a compressor is frequency-regulated,’ adds Große-Kracht.

The BITZER Group is the world’s largest independent manufacturer of refrigeration compressors. BITZER is represented across the globe through distribution companies and production facilities for reciprocating, screw and scroll compressors, pressure vessels and heat exchangers. In 2016, 3,400 employees generated sales of €680 million.

Overview of images

Images may only be used for editorial purposes. They can be used free of charge if the source is given – ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.

BITZER Kühlmaschinenbau GmbH

Peter-Schaufler-Platz 1

71065 Sindelfingen

Telefon: +49 7031 932-0

Telefax: +49 7031 932-147

http://www.bitzer.de

Head of Public Relations

Telefon: +49 (7031) 932-4327

Fax: +49 (7031) 932543-70

E-Mail: patrick.koops@bitzer.de

![]()