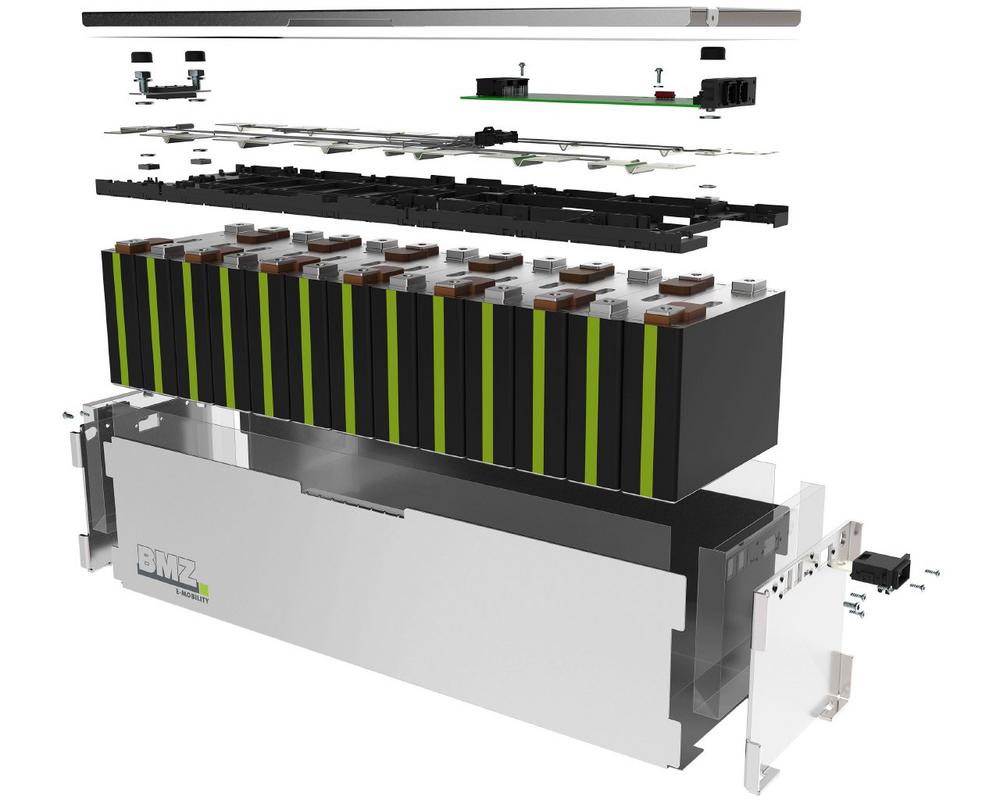

Module production with laser welding robots

These customer-specific BMZ lithium-ion batteries use battery cells from the automotive industry. The new technology fulfils the highest safety and stability requirements. The high-quality installed automotive cells withstand 4,000 charging cycles. Module production at BMZ is handled fully automatically by laser welding robots. BMZ supports its customers in building the car of the future, helping them achieve new dimensions of mobility. Electric vehicles are quiet, reliable, and low-emission. They use the best infrastructure for recharging.

Batteryuniversity Tests Large-Scale Batteries

BMZ is working closely with DAKKS accredited Batteryuniversity GmbH, an independent subsidiary of the BMZ Group, to meet all of the safety requirements and obtain all permits required for global shipment and sale. For the customer, the advantage is that we can handle all required nationally-specific permits quickly and reliably from a single source. New test benches at Batteryuniversity GmbH are able to test large batteries for electric cars or forklifts. The 120 kilonewton BU shaker can handle loads of up to 800 kilogrammes, and can test noise profiles, sine sweeps, superimposed sine waves, and shock impulses.

BMZ Germany GmbH

Zeche Gustav 1

63791 Karlstein

Telefon: +49 (6188) 9956-0

Telefax: +49 (6188) 9956-900

http://www.bmz-group.com

Head of Global Marketing & Communication

Telefon: +49 (6188) 9956-770

E-Mail: Susanne.Kaschub@bmz-group.com

![]()