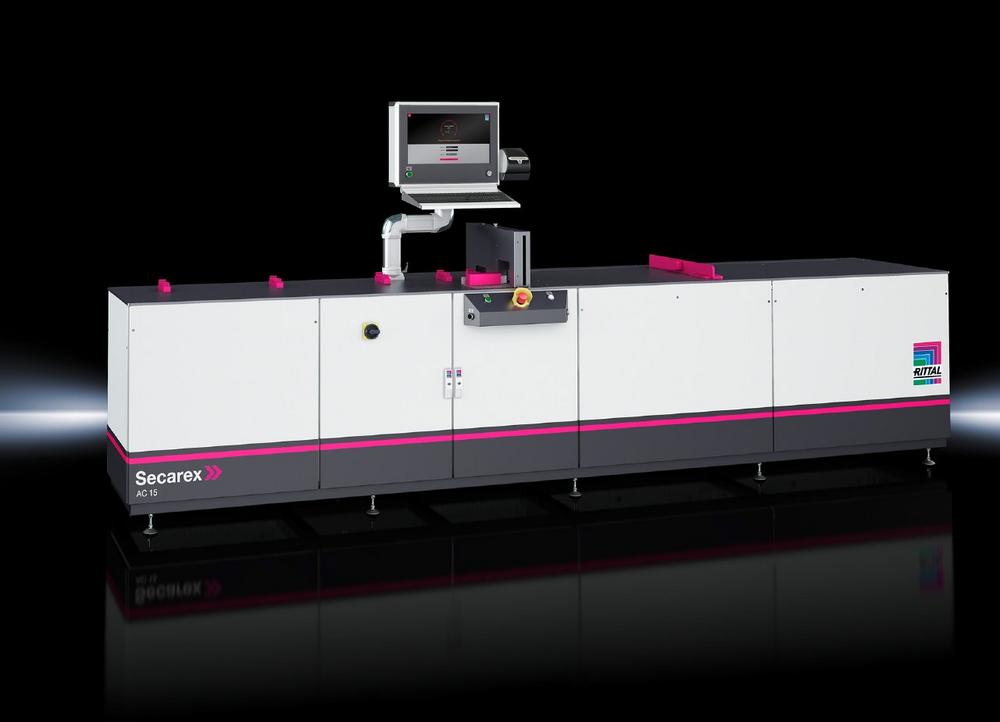

Cutting support rails and cable ducts to the right length is a task that many workshops still perform by hand. The required rail length is measured on the mounting plate and the support rail is then cut to the appropriate length. The rail may also be labelled using a felt-tip pen so that it can be allocated to an enclosure and, where necessary, to a position in the enclosure. The Secarex AC 15 cutting centre from Rittal, however, makes these tasks much easier, quicker and more efficient. An automatic length stop ensures accurate custom-cut rails.

The cutting centre is very convenient to use, operating via an industrial PC with a keyboard and trackball. The process of cutting the rails to length is particularly efficient when the dimensions are transferred directly from design planning, which can be performed on the EPLAN Pro Panel, for example. Where multiple rails are required, the cutting centre calculates the optimal denomination in order to minimise waste. As part of this process, the integrated label printer also marks the finished rails so they can be easily assigned during the subsequent assembly process. The cutting centre is able to cut DIN support rails, C rails and cable ducts in all standard sizes.

Cutting, bending and hole-punching copper bars

Copper bars used in switchgears for power distribution or as busbars must also be processed in the electronics workshop. In addition to cutting to length, other work steps such as bending or punching holes are often also necessary. These tasks can be performed more quickly and safely using the CW 120 (Copper Workstation) bending and hole-punching unit. The unit is available in two versions: A stationary benchtop unit for cutting, bending and hole-punching busbars, with external hydraulic supply. A mobile version designed with castors for flexible use in the workshop, with integrated hydraulic pump. A single simple 230-V mains connection is required for the supply. Both versions can process rails at a width of up to 120 mm and thickness of up to 12 mm. Round holes can be punched in sizes between 6.6 mm and 21.5 mm. For slots, a maximum width of 21 mm and length of 18 mm are possible. Stamps and dies for round holes and slots are available as accessories and come in different sizes.

The machines produced by Rittal Automation Systems for processing support rails, cable ducts and busbars are a perfect complement to semi-automated production in switchgear manufacturing. They simplify many of the tasks that previously had to be performed manually, making the process far more efficient. The outcome: Lower costs and better quality.

Rittal, headquartered in Herborn, Germany, is a leading global provider of solutions for industrial enclosures, power distribution, climate control and IT infrastructure, as well as software and services. Systems made by Rittal can be found in more than 90 percent of all global branches of industry, including mechanical and plant engineering, food and beverage production and in IT and telecommunications.

The wide range of products from the global market leader includes configurable enclosures, whose data is available throughout the entire production process. Intelligent Rittal cooling solutions with up to 75 percent lower energy and CO2 consumption can communicate with the production environment and enable predictive maintenance and service concepts. Innovative IT solutions ranging from IT racks and modular data centres through to edge and hyperscale computing solutions all form part of the portfolio.

Leading software providers EPLAN and Cideon complement the value chain, providing interdisciplinary engineering solutions, while Rittal Automation Systems offer automation systems for switchgear construction. Rittal delivers within 24 hours in Germany – precisely as needed, flexibly and efficiently.

Founded in Herborn in 1961, Rittal is the largest member company in the owner-operated Friedhelm Loh Group. The Friedhelm Loh Group operates worldwide with 18 production sites and 80 international subsidiaries. The entire group employs more than 11,300 people and generated revenues of around €2.2 billion in 2016. In 2017, it was named one of Germany’s leading employers by the Top Employers Institute, for the ninth year running. Within the scope of a Germany-wide survey, Focus Money magazine identified the Friedhelm Loh Group as one of the nation’s best providers of vocational training for the second time in 2017.

For more information, visit www.rittal.com and www.friedhelm-loh-group.com.

Rittal GmbH & Co. KG

Auf dem Stützelberg

35745 Herborn

Telefon: +49 (2772) 505-0

Telefax: +49 (2772) 505-2319

http://www.rittal.de

Corporate Communications

Telefon: +49 (2772) 505-2693

E-Mail: koch.hr@rittal.de

Corporate Communications

Telefon: +49 (2772) 5052527

E-Mail: wiechens-schwake.r@rittal.de

Corporate Communications

Telefon: +49 (2772) 505-1328

E-Mail: abels.c@rittal.de