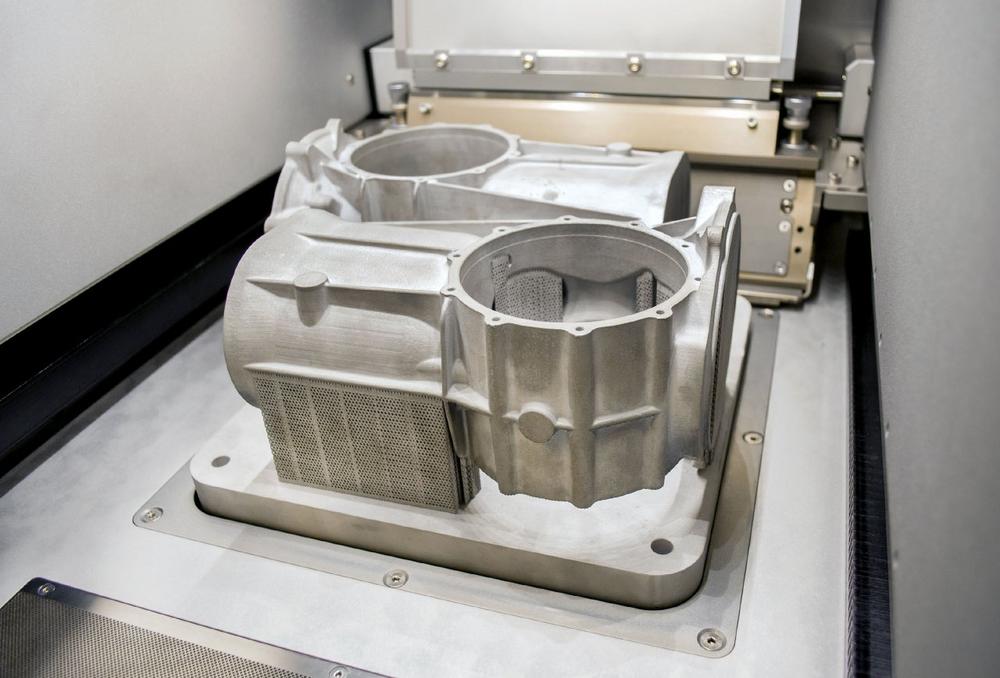

Founded in 2014, the Light Alliance now has more than 30 members from a variety of disciplines. It brings people from all applications together. From the engineers who develop and produce lightweight, complex products, and the companies in the automotive and aerospace industries who utilize these products, to 3D printer suppliers; the Additive Alliance is focused on the exchange of cross-industry experiences and joint research. Its ultimate goal is to develop innovative solutions along the entire value chain.

As a manufacturer of X-ray and CT systems designed to test and analyze a wide range of components and materials, Yxlon’s experience in quality assurance completes the picture by offering a non-destructive way to inspect intricate additively manufactured parts. Simultaneously, Yxlon is now privy to the latest in R & D and additive manufacturing applications, helping them better understand how to best provide testing solutions for the field. Every manufacturing technique, material or composite, as well as complexity and functionality of a component brings its own unique challenges that require tailored test solutions. By sharing experiences through each step of the development, these challenges can be recognized before entering the mainstream market. With an unparalleled online resource database, members have free access to all study results, lecture notes, and finding reports produced by the work group. This membership also helps Yxlon to expand its competence and enable better support to those customers using 3D printing in their manufacturing and design tailor-made solutions for their specific applications.

YXLON International designs and produces radioscopic and CT inspection systems for the widest variety of applications and fields. Whether situated in the aviation & aerospace, automotive or electronics industry, our customers are among the largest producers, major enterprises that place their confidence in our quality worldwide.

The name YXLON stands for assurance and quality for all types of cast parts, tires, electronic components, turbine blades, welded joints and a lot more. Our product portfolio includes X-ray systems for installation in radiological inspection envelopes, universal X-ray inspection systems on the basis of fully shielded devices, as well as solutions specific to a customer. Whether in manual, semi or fully automated operation, our inspection systems are ideal for deployment in research & development and can be integrated into any production process.

CT systems have been an integral part of our product portfolio since as far back as 2003. Computed tomography provides a three-dimensional insight into inspection items, thus enabling the analysis of inner structures, dimensional measurement tasks in metrology applications or actual-to-nominal comparisons to CAD data, to name only a few examples. Besides delivering a more precise inspection evaluation when compared with radiography, computed tomography also provides valuable information about the production process. Above and beyond such advantages, our microfocus systems permit highly detailed looks into the most intricate structures and tiniest components.

With our headquarters in Hamburg, sales and service locations in Tokyo, Osaka, Hudson (Ohio), San Jose (California), Beijing, Shanghai, Hattingen and Heilbronn, as well as a network of representatives in over 50 countries, as YXLON we’re local for our customers all over the world.

Since 2007, YXLON International has been a member of the COMET Group.

YXLON International GmbH

Essener Bogen 15

22419 Hamburg

Telefon: +49 (40) 52729-0

Telefax: +49 (40) 52729-170

http://www.yxlon.com

Marketing Communications

Telefon: +49 (40) 52729-404

Fax: +49 (40) 52729-170

E-Mail: gina.naujokat@hbg.yxlon.com

Sales Manager Science & New Materials

Telefon: +49 (40) 52729-205

E-Mail: philip.sperling@hbg.yxlon.com