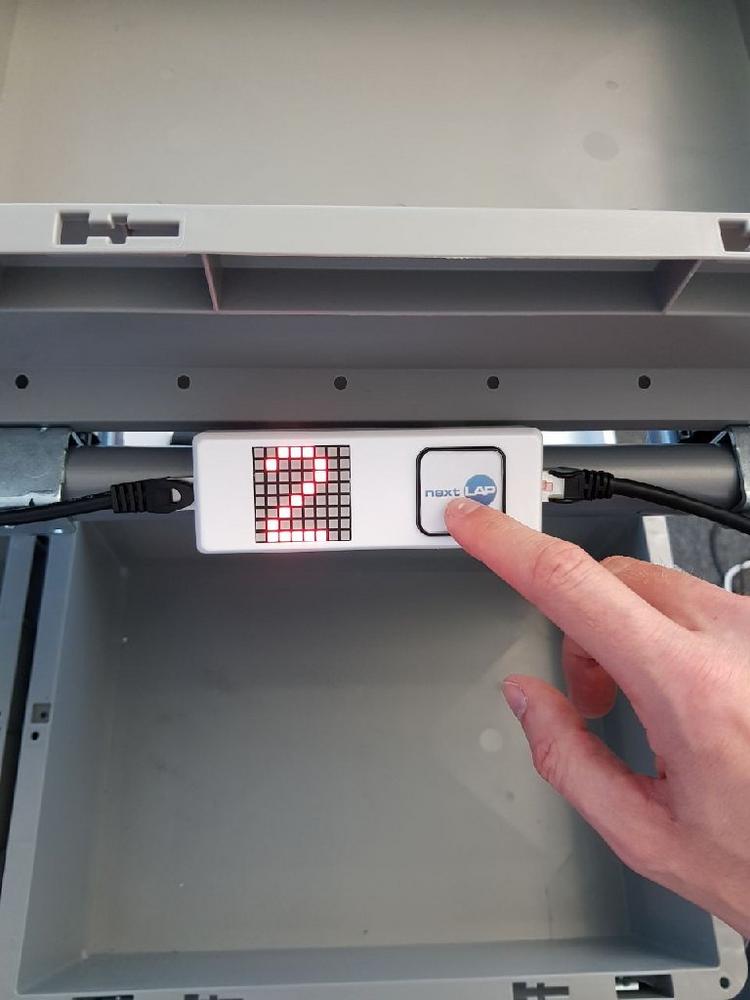

Thanks to the modular SmartRack system, which is employed, for example, in the automotive sector, all kinds of order-picking processes can be easily digitised and automated, from pick-to-light, pick-to-box, eKanban and multi-pick to forward/reverse order-picking of batches and sequences. To do this, storage racks and areas are equipped accordingly with IoT components and connected to nextLAP’s IP/1 platform. The system includes buttons with a processor and LED screen, a controller and a screen or tablet. Because the system has been designed like an app, its operation and configuration can be tailored precisely to the various areas of application.

All data is collected centrally in the platform, where it is processed in real time. The system can be connected to existing MES and ERP systems. The big data obtained from the digitised process is used to generate improvement measures and alternative action (using algorithms and artificial intelligence). Building on IoT, SmartRack thus combines conventional automation features of order-picking processes with digitisation features involving big data and machine learning.

SmartRack keeps administrative costs low, as it is quick and easy to install, configure and maintain, with no IT expertise or knowledge of automation required. The solution is leased “as a service” on a monthly basis with no fixed term; usage, maintenance and support are included.

Electronics factory expects potential savings of around 30 percent

At Limtronik, where the SmartRack system is already in its launch phase, savings of approximately 30 percent are anticipated on the standard costs for order-picking processes (routes, ergonomics, inventories, process times etc.). SmartRack enables the flagging of defective parts, incorrect components in the box or special retrievals; the control station/group leader to be called; real-time inventory management; replenishment control based on real-time consumption; flexible repositioning and reconfiguring by the technical department; online monitoring of the availability of the SmartRack components, and much more.

Limtronik will demonstrate the SmartRack and all its components at HANNOVER MESSE 2018 at stand D26 in hall 7 (joint stand with SEF Smart Electronic Factory e.V.).

nextLAP GmbH was founded in 2014 by former Audi managers and has offices in Munich and Mountain View, California. The company develops IoT-based production and logistics solutions aimed at the automotive industry and other sectors, which combine cloud technology, AI, big data and in-house developed IoT hardware. The SmartRack product family allows users to digitise production and logistics processes (e.g. order-picking processes) themselves, as the solution can be quickly and easily installed, configured and maintained, with no IT knowledge required. The big data obtained from the digitised process is used to generate improvement measures and alternative action (using algorithms and artificial intelligence). nextLAP’s solutions are leased “as a service” on a monthly basis with no fixed term; usage, maintenance and support are included. The company’s customers include leading premium automotive manufacturers in Germany and the USA. (www.nextlap.de)

nextLAP GmbH

Hofmannstraße 61

81379 München

Telefon: +49 (89) 999533725

http://www.nextlap.de

punctum pr-agentur GmbH

Telefon: +49 (211) 9717977-0

E-Mail: pr@punctum-pr.de

President

Telefon: +49 (89) 999533725

E-Mail: aziemke@nextlap.io