The customer awarded the final acceptance certificate following a very short revamp and successful re-commissioning.

The aim of the revamp – to reduce the force on the gearbox during the AOD converter refining process that had been causing uncontrolled vibrations and damage to the bull gear, bearings and foundation of the converter drive – has been fully achieved.

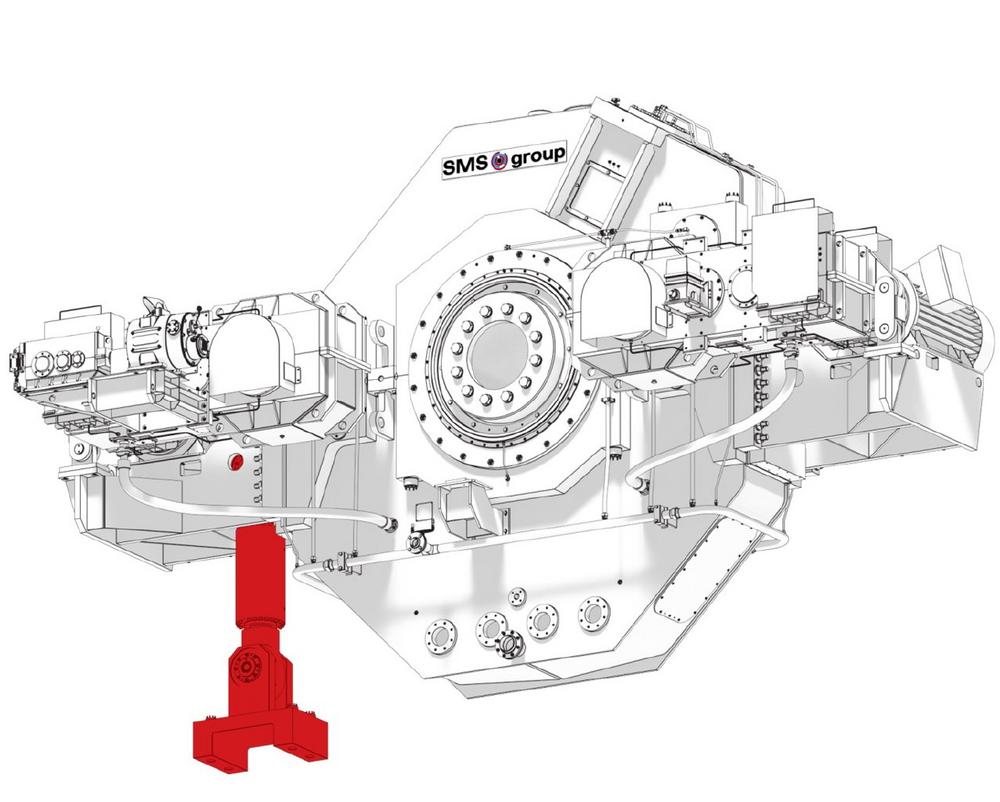

SMS group supplied the torque retainer made in Germany as a compact electro-hydraulic unit.

Engineering and erection supervision were also included in the scope of supply. The revamp took place during a scheduled shutdown. The converters resumed operation and were running at full production capacity at an interval of two days. The first converter reached the guaranteed values three days after hot commissioning, while the second converter had already attained the guaranteed values after only one day.

Both, cold and hot commissioning were completed jointly with the customer. The good cooperation and high commitment of the teams from Columbus and SMS group made this success possible.

Gus Schepers, Project Manager Engineering Projects, Columbus, is completely satisfied: “We rely on SMS group technology. The torque retainer from SMS group is an innovative target-oriented solution consisting of tried and tested components, which means the whole system is very easy to maintain. Given the reduced maintenance costs, we project a very good return on investment.”

SMS group is a group of companies internationally active in plant construction and mechanical engineering for the steel and nonferrous metals industry. It has some 13,500 employees who generate worldwide sales of more than EUR 3 billion. The sole owner of the holding company SMS GmbH is the Familie Weiss Foundation.

SMS group GmbH

Eduard-Schloemann-Straße 4

40237 Düsseldorf

Telefon: +49 (211) 881-0

Telefax: +49 (211) 881-4902

http://www.sms-group.com

Fachpresse

Telefon: +49 (211) 881-4449

Fax: +49 (211) 881-774449

E-Mail: thilo.sagermann@sms-group.com

![]()