The aim of predictive maintenance is to proactively maintain machines and equipment and to minimise downtimes by identifying faults before they appear. Predictive Process Control is the next big step – using data, process anomalies can be detected early and proactive, automated countermeasures are taken.

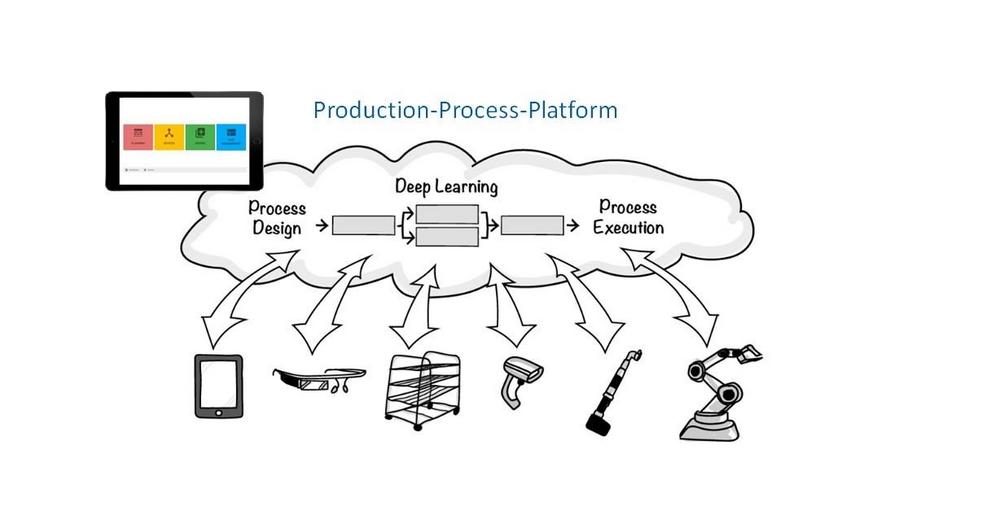

In order to implement this scenario, nextLAP has developed the IP/1 production process platform, which serves as a basis for the planning, development, management and monitoring of entire process chains. The software uses relevant data sources to create a digital real-time overview of the production and logistics processes. Various IIoT technologies developed by nextLAP, including mini PCs and intelligent devices, are connected to the platform. The production process platform instantly recognises anomalies, autonomously identifies potential problem-solving scenarios and takes countermeasures before an incident can actually occur.

Algorithms make autonomous decisions for improvement

The platform collects various process parameters from production and logistics – for example, when and where a part is installed, machine throughput or the location of a truck that is delivering parts a factory. Based on this real-time data, the resulting empirical values get pooled on the production process platform and put into context, and out of this nextLAP develops algorithms that can make autonomous decisions for improvement and feed them back into the process.

“Data science methods are nothing new for the factories – they are often well-prepared for predictive maintenance and servicing. In the realm of digitisation, Predictive Process Control is the icing on the cake and holds a great deal of potential for value creation. That’s why we’ve developed an easy-to-use, effective platform that’s already being used by leading automotive manufacturers”, says the Managing Director of nextLAP GmbH, André Ziemke.

nextLAP GmbH was founded in 2014 by former Audi managers and has offices in Munich and Mountain View, California. The company develops IIoT-based production and logistics solutions aimed at the automotive industry and other sectors, which combine cloud technology, AI, big data and in-house developed IIoT hardware. The SmartRack product family allows users to digitise production and logistics processes (e.g. order-picking processes) themselves, as the solution can be quickly and easily installed, configured and maintained, with no IT knowledge required. The big data obtained from the digitised process is used to generate improvement measures and alternative action (using algorithms and artificial intelligence). nextLAP’s solutions are leased "as a service" on a monthly basis with no fixed term; usage, maintenance and support are included. The company’s customers include leading premium automotive manufacturers in Germany and the USA. (www.nextlap.de)

nextLAP GmbH

Hofmannstraße 61

81379 München

Telefon: +49 (89) 999533725

http://www.nextlap.de

President

Telefon: +49 (89) 999533725

E-Mail: aziemke@nextlap.io

punctum pr-agentur GmbH

Telefon: +49 (211) 9717977-0

E-Mail: pr@punctum-pr.de