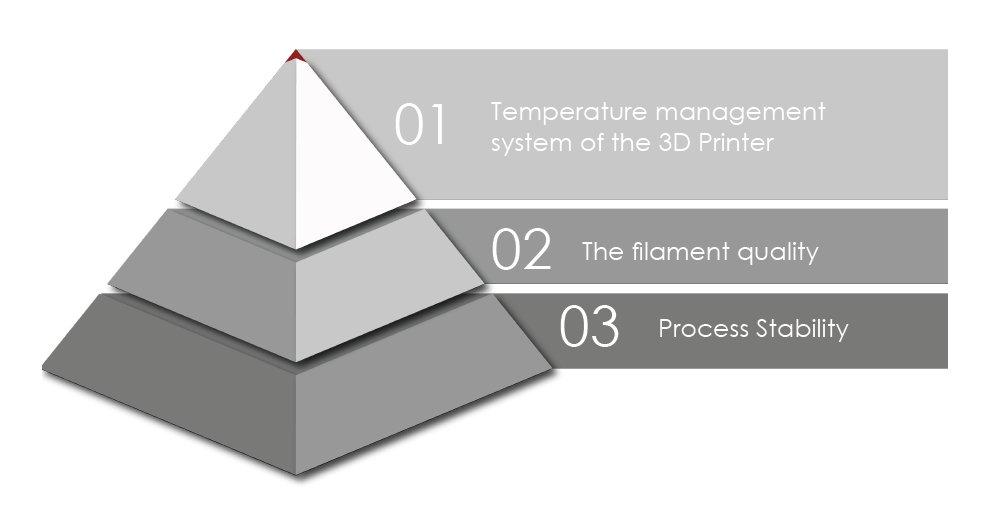

1. Temperature management system of the 3D printer

2. The filament quality

3. Process stability

PEEK`s Usage for its Chemical Resistance

PEEK can be used in very demanding applications as replacement of metal. Most notably aerospace, automotive and chemical sectors prefer PEEK because of its strength, durability and chemical resistance. It exhibits excellent resistance to a wide range of organic and inorganic chemicals.

Key Applications

– Piston Units

– Seals

– Bearings

– Washers

– Fasteners

– Various active components in applications such as

»» Transmission systems

»» Braking Systems

»» Air-conditioning Systems

Chemical Testing of 3D Printed PEEK Parts

The chemical resistance of each polymer is mainly determined by the chemical structure of the material and the strength of the weakest link in this specific structure. Because of this, different processing methods might affect the chemical resistance of a polymer. A chemical test is conducted on 3D printed PEEK parts to examine the changes in chemical properties.

Test specimens of Apium PEEK 450 Natural were immersed in different chemicals at constant room temperature 24,5 °C for a minimum of 7 days. In the first step, chemical compatibility was assessed via weight or dimensional changes, physical degradation and discoloration.

Apium Additive Technologies GmbH

Siemensallee 84

76187 Karlsruhe

Telefon: +49 (721) 13 20 95 0

Telefax: +49 (721) 13 20 95 77

http://www.apiumtec.com/

Head of Marketing and Quality Management

Telefon: +49 (721) 6803087-0

E-Mail: pinar.karakas@apiumtec.com

![]()