World first: automated sensor integration using functional foil bonding

Kurz will be demonstrating, for the first time ever, the FFB (Functional Foil Bonding) sensor integration process on a machine that was recently developed by its subsidiary Baier. This method enables touch sensors to be integrated into plastic components by fully mechanized means. The process can be connected directly to the injection mold. The FFB machine can be integrated into component production lines, and can operate in both inline or offline mode. The FFB operation can be performed by machine operators or, to a large extent, automated, thereby providing a never-before-seen ability to cost-effectively integrate sensors in serial production. This integration solution also has advantages over conventional methods in regard to durability, which will help achieve the stringent requirements of industry.

Integrated surface protection and reliable readability

Kurz has developed top coats that are highly resistant to a wide variety of influences, for example abrasion, scratches, chemicals and UV radiation. Visitors to the Fakuma booth will be able to see coatings that have also been tailored to the specific requirements of HMI surfaces. These novel coatings ensure easy, distortion-free readability of control panels and displays from various viewing angles and under different lighting conditions. Top coats with customer-specific features can also be produced: for high-gloss displays with exceptional color brilliance and a contrast-rich image; for matte anti-glare or even completely anti-reflective screens.

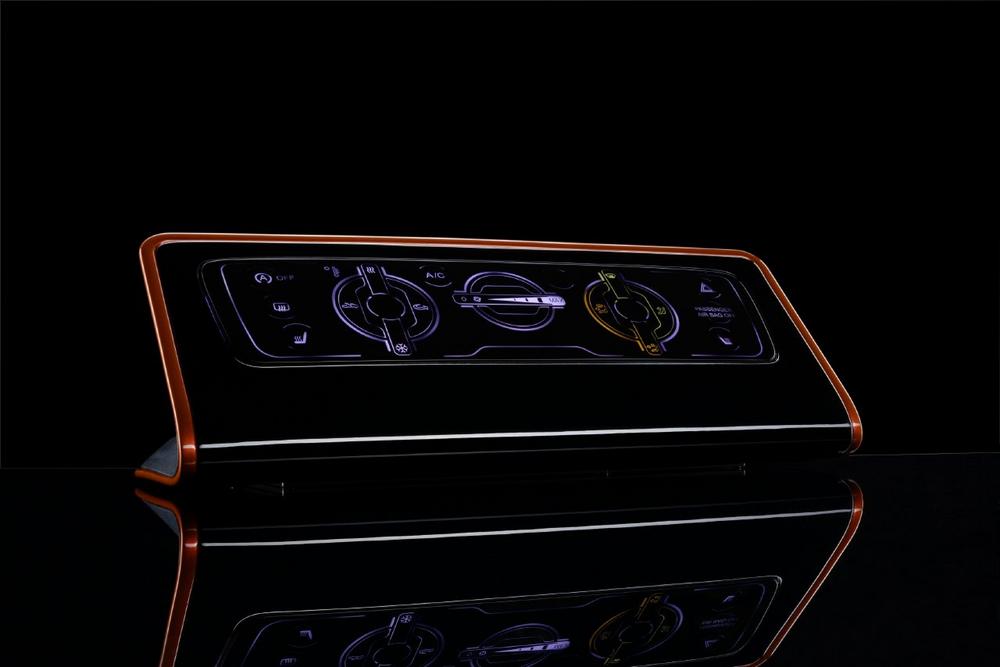

Design effects like day and night

New possibilities for touch-controlled surfaces and light designs using the sensor technology from Kurz subsidiary PolyIC will be presented with the aid of a number of demonstrators. On display will be expressive day/night effects with creative design flips. Designs that are opaque under daylight conditions but change their appearance in surprising ways on touch activation. They become bathed in mood-setting ambient lighting, and the color and intensity of the light can be changed by means of sliders or knobs. Sophisticated designs inspired by nature and technology that are partially or fully backlit, or which exhibit varying levels of transparency. Also on display will be silk-screen printed designs from Kurz subsidiary Burg Design that develop a special depth effect when backlit.

Novel soft-touch surfaces

For in-mold decoration of plastic components, Kurz has developed unique soft-touch surfaces. Various haptic effects can be produced, from silky smooth, to velvety, right through to strikingly grippy surfaces. The soft-touch haptics can be combined with a wide range of visual designs, offer high surface resistance, and have a sound-optimizing effect thanks to their acoustic damping properties.

Zum Unternehmen: Die KURZ-Gruppe ist ein weltweit führendes Unternehmen der Heißpräge- und Beschichtungstechnologie. KURZ entwickelt und produziert auf Trägerfolien applizierte Dekorations- und Funktionsschichten für verschiedenste Einsatzgebiete: metallisierte, pigmentierte und holografische Prägefolien für Verpackungen oder Printprodukte, Oberflächenfinishes für Elektronikgeräte oder Automobilteile, Schutz- und Dekorlacke für Möbel oder Haushaltsgeräte, Echtheits-Kennzeichen für Markenartikel, Metallic-Applikationen für Textilien und differenzierte Beschichtungen für viele weitere Anwendungen. Mit über 5.000 Mitarbeitern in 14 Werken in Europa, Asien und den USA, 24 internationalen Niederlassungen und einem weltweiten Netz an Vertretungen und Verkaufsbüros fertigt und vertreibt die KURZ-Gruppe eine umfassende Produktpalette zur Oberflächenveredelung, Dekoration, Kennzeichnung und Fälschungssicherheit, abgerundet durch ein umfangreiches Programm an Prägemaschinen und Prägewerkzeugen. Darüber hinaus investiert KURZ kontinuierlich in neue Technologien und entwickelt innovative Lösungen für die Integration von Funktionen in Oberflächen.

About KURZ: The KURZ Group is a global leader in hot stamping and coating technology. KURZ develops and manufactures decorative and functional layers applied to carrier foils for a large variety of applications. The range includes metallized, pigmented and holographic stamping foils for packaging or print products, surface finishes for electronic devices or automotive parts, protective and decorative lacquers for furniture or household appliances, authenticity features for brand name items, metallic applications for textiles, and different types of coatings for many other applications. With over 5,000 employees in 14 production plants in Europe, Asia and the USA, 24 international subsidiaries and a global network of agencies and sales offices, the KURZ Group manufactures and sells a comprehensive range of products for surface finishing, decoration, marking and counterfeit protection, rounded off by an extensive range of stamping machines and stamping tools. KURZ also continuously invests in new technologies, and is developing innovative solutions for integrating functionality into surfaces.

LEONHARD KURZ Stiftung & Co. KG

Schwabacher Str. 482

90763 Fürth

Telefon: +49 (911) 7141-0

http://www.kurz-world.com

Presse

Telefon: +49-911-7141-9638

Fax: +49 (911) 7141-9640

E-Mail: lucie.mengel@kurz.de

![]()