Repairing machines before they break down – this is made possible by predictive maintenance. The experts at Arno Arnold have been studying the extent to which this affects the development of protective machine covers from an early stage. One of the many ideas is the “self-signaling bellows”. As the company explains, the crucial part is the intelligent networking of sensors in the bellows. Depending on the elasticity of the bellows or protective cover in machine operation, higher demands are placed on the sensor elements. The result is a “smart safety cover” that provides high process reliability and minimizes the fault rate in the machine. The design of the bellows wall comprises a double-layer laminate as a minimum, with the sensor elements inserted into the laminate. This option protects the sensors from external factors. The signals can form an alarm system as part of the device or be integrated into an existing data system. Another interesting option, the company reports, is that the bellows are able to trigger an order when they need replacing. This could ensure uninterrupted operation of the machine and save valuable time for the machine operator’s materials management department.

Arno Arnold has been working with intelligent communication protective systems for decades. This resulted in the first application to register the property rights for a “bellows with integrated detector device” in 1985, which led to granting of a patent (DE 35 32 702) in 1993. In view of the multitude of sensors available today, the company is now making what was a pioneering achievement back then IOT-compatible. A protective cover that re-orders parts itself will fit in well in the completely networked, unmanned production systems of the future.

Sensor systems integrated into protective covers are supplying increasingly precise data about real loads as part of Industry 4.0 concepts. This offers many advantages:

- Predictive maintenance

- Precise planning of spare parts and spare parts procurement

- High-availability package – prompt notification when wear limits are reached

- Prevention of unauthorized spare parts copies

- Remote monitoring for unmanned operation

Roover-Connect: Arno Arnold is extending its Roover roof covering team to include the Roover-Connect product. This light-permeable, seamed roof solution for large machine roofs opens up to provide access to the work table for unobstructed crane loading. The Roover-Connect is made of transparent material that is combined with light-permeable or different colored material. In addition to the ergonomic benefits, this allows operators to save on costs for operation and maintenance of work space lighting in the long term. Arno Arnold is unveiling the latest design (version 4.0) at AMB 2018

Roller systems as protection for man and machine: when safety is required in production and automation, machine coverings i.e. additional safety devices are used. We at the protective cover manufacturer Arno Arnold understand the needs of machine builders and also offer roller systems for areas with limited space. These roller covers – which are only available as customized solutions – offer protection particularly where space is limited. An integrated spring motor ensures reliable rolling of the plastic or steel sheet mounted on the moving axis.

Arno Arnold describes its WMB spiral springs as aids to machine protection. They provide machine protection that creates optimal conditions for safe functioning of shafts, columns and spindles. Permanent, maintenance-free spindle protection is ready for delivery within 24 hours. You can also see this at AMB 2018.

End position damping: Machines with very high dynamics can cause the individual folds to continue oscillating when the machine stops. Application of force to the moving parts by the dynamics and net weight is absorbed by damping elements in the ramp frame. Arno Arnold shows how this works at its exhibition stand.

Other interesting protective cover solutions: Visitors also have the chance to see bellows with high puncture strength. In modern turning and milling centers, things literally get thrown around. Doors, inspection windows, housings and protective covers not only have to withstand a constant hail of chips. If cutting plates burst, tools break off or even workpiece debris flies about, the puncture strength determines the extent of damage to man and machine. Modified covers from Arno Arnold absorb impact energies of over 400 joules. Combined with other materials, the retention capacity can be increased above 1,100 joules, as confirmed by an extensive series of tests to DIN EN 12417. Tests for determining the puncture strength of protective systems for lathes are defined in DIN EN 12415. Arno Arnold offers a protective cover that has passed the extensive tests set out under DIN EN 12415.

Also on display: The miniature sample of a customized application consisting of a rear wall and 2 side walls in a winglet design. It shows the advantage of Fix & Finish at various levels (2 or more). The back wall can be moved in 2 axes, the side walls show the covering option in the 3rd axis.

Elegano 100 folds is also of interest. The exhibit shows how small the Lmin of 100 folds can be with a covering from Arno Arnold: 100 folds in 190 mm.

Other interesting exhibits include Strapano, the modular minimalist, the leading design of the Elegano protective cover with a Lmin per fold of just 1.99 mm, the Perigano with a Lmin < 1.8 mm, which is a world first and is ideal for use both vertically and horizontally, and the transparent Perigor.

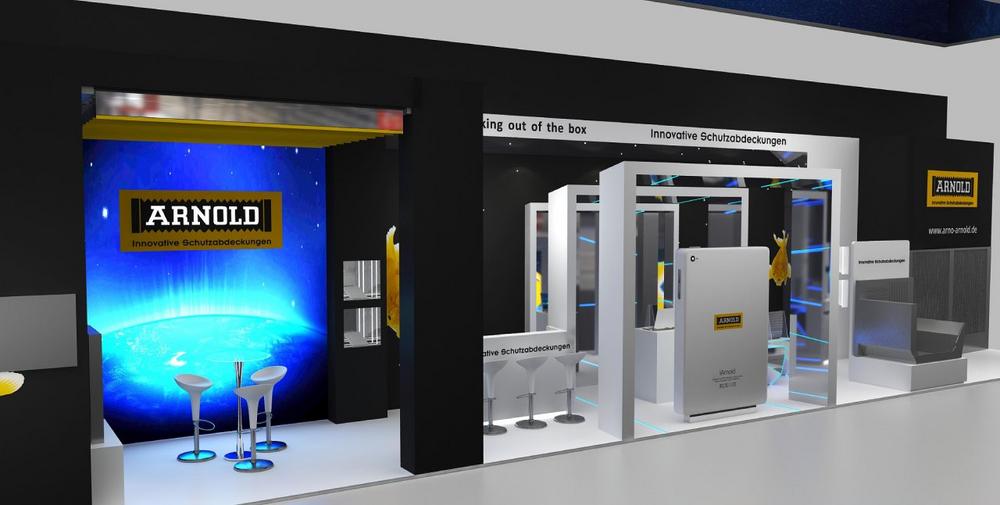

So there is plenty to see at the Arno Arnold stand (Hall 10/A01) at the AMB from September 18. – 22. 2018.

ARNO ARNOLD GmbH

Bieberer Str. 161

63179 Obertshausen

Telefon: (+49) 6104 4000-0

Telefax: +49 (6104) 400099

http://www.arno-arnold.de

Telefon: 06104 4000-20

Fax: +49 (6104) 4000-11

E-Mail: s.mang@arno-arnold.de