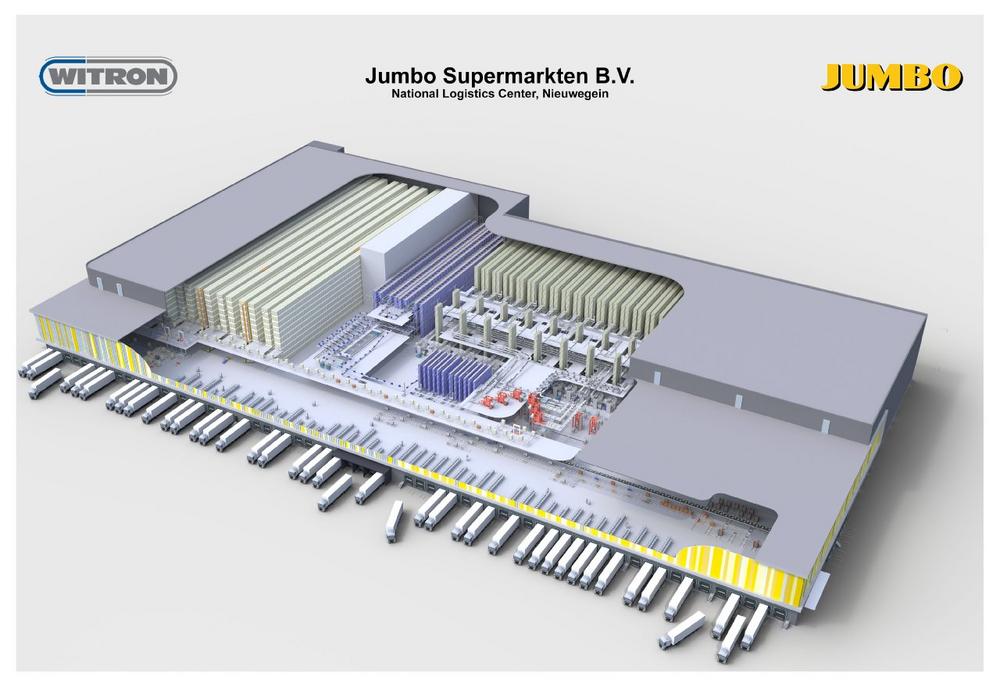

In the first phase the facility, with a size of 45,000 square meters located near Utrecht, will supply all Jumbo stores with 12,000 different dry goods. In this stage, the distribution center is designed for peak pick performance of 2,000,000 cases per week. To achieve this goal, Jumbo relies on WITRON’s Order Picking Machinery (OPM) solution – with a total of 20 Case Order Machines (COMs), expandable to 32 COMs – providing a fully automated case picking operation onto roll containers. In addition, WITRON will be installing its semi-automated Dynamic Picking System (DPS), which is used to pick small-volume items highly dynamically into totes at 30 multi-functional picking workstations. Both systems are successfully implemented in food and general merchandise retail projects across the globe. Replenishment and pick front profiling are done fully automatically by means of stacker cranes. A high bay warehouse with 22,000 pallet locations is located in front of the picking areas and is used for the Car Picking System (CPS), which is used to pick bulky goods from flow channels in a route-optimized manner. Replenishment has also been automated for this product range.

Once all customer orders are picked and consolidated in the various sub-systems, they are manually prepared for dispatch in the shipping area.

Innovative conveyor system elements and high-speed stacker cranes developed and manufactured by WITRON’s subsidiary FAS, ensure an optimally linked and highly dynamic material flow. The “National Logistics Center” will be controlled by WITRON’s logistics software, which is integrated into Jumbo’s entire IT eco-system through WITRON’s software portal 4.0.

As a general contractor, WITRON is responsible for the entire design and realization of all IT, control engineering, and mechanical components. The order scope also includes the operational system support, as well as servicing, and maintenance of the system. The WITRON OnSite team will be located directly at the Jumbo site and will ensure continuous high availability of all components and logistics areas.

The Dutch food retailer, Jumbo Supermarkten B.V. headquartered in Veghel generated a revenue of 7,01 billion Euros in 2017. The company employs some 70,000 staff members and distributes its products via the store brand Jumbo as well as through its extensive online portal.

WITRON Logistik + Informatik GmbH, established in 1971 (headquarters Parkstein, Bavaria, Germany), designs, realizes, and operates customized logistics and material flow systems that generate sustainable competitive advantages for its clients. WITRON has all the decisive key elements of a successful project under one roof: logistics design, information and control technology, mechanics design and production, as well as functional responsibility as general contractor for logistics.

To date, WITRON has successfully realized more than 2,000 logistics projects in different business sectors. It is not without good reason that WITRON is one of the most innovative market leaders worldwide. We pave the way for our customers‘ decisive logistic advantages in the conceptual stages of system design. Only through design, realization, and the service of a system is it possible to take over real system and functional responsibility.

For many years, numerous top companies throughout Europe and North America have relied on WITRON’s solutions to successfully and cost-efficiently operate their distribution centers. The high number of existing customers (80%) – that means customers that have already realized two or more logistics systems with WITRON – shows how satisfied the customers are with WITRON.

WITRON Logistik + Informatik GmbH

Neustädter Str. 21

92711 Parkstein

Telefon: +49 (9602) 600-0

Telefax: +49 (9602) 600-211

http://www.witron.de

Vertrieb Logistiksysteme

Telefon: +49 (9602) 600-340

E-Mail: wedl@witron.de