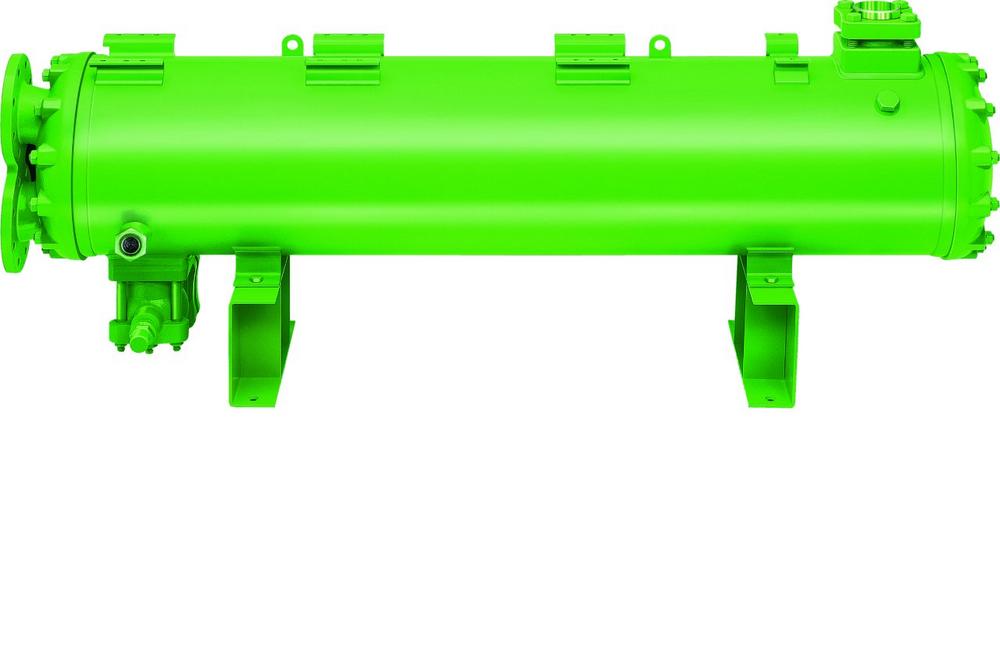

At Chillventa 2018, BITZER is launching the world premiere of its new water-cooled condensers for fresh water and seawater, which have bigger capacities than before. These new condensers with capacities up to 1 MW possess the features of the well-known K condensers, such as a compact design, low-fouling exchange tubes and high corrosion resistance. Furthermore, BITZER is presenting its CRF high-efficiency condensers and SQD high-efficiency shell and tube evaporators from its recent acquisition. The unique square-shaped evaporator reaches the highest efficiency available in the industry for a dry-expansion heat exchanger. A part of BITZER’s HEXPV stand is dedicated to CO2 solutions, displaying the new WGC shell and tube gas cooler – which is designed for transcritical applications, has 120-bar design pressure and ensures high pressure/thermal fatigue resistance – and a liquid receiver from the proven F series for subcritical CO2 applications.

Alongside its core business of compressors, BITZER is systematically expanding its portfolio of heat exchangers and pressure vessels with manufacturing sites around the world. One of the key quality characteristics of BITZER heat exchangers is the fact that they’re brazed. They therefore boast greater tightness and a more consistent coating than rolled heat exchangers. All BITZER HEXPV products are HFO-ready. Andrea Serena, Global Manager Heat Exchangers and Pressure Vessels at BITZER, explains: ‘Taking over the shell and tube heat exchanger product group from Alfa Laval SpA has made us the world’s largest independent manufacturer of shell and tube heat exchangers. We now have at our disposal huge expertise in dry-expansion evaporators, flooded evaporators and condensers for fresh-water and seawater applications with a capacity of up to 2,000 kW. This is an important step in further developing our HEXPV segment.’

Going flexible with product customisation

Flexibility is the top priority when it comes to customer requirements, which is why BITZER offers customers the choice between standard products and those products tailored to their specific requirements. ‘With our project for heat exchanger and pressure vessel adjustment, we’re addressing our partners’ demands for flexible product solutions,’ says Serena. ‘Horizontal liquid receivers and water cooled condensers from the F and K series are just the beginning, with more of our products to follow.’ Up to five product components can be relocated from the standard position within a space established by BITZER, from the inlet and outlet refrigerant connections to the welded support legs. In this way, BITZER meets customers’ special requirements in terms of dimensions and functions. They can simply enter the new measurements either in the approval drawing in the document section of the BITZER website or using the BITZER software.

■

The BITZER Group is the world’s largest independent manufacturer of refrigeration compressors. BITZER is represented across the globe through distribution companies and production facilities for reciprocating, screw and scroll compressors, heat exchangers and pressure vessels. In 2017, 3,500 employees generated sales of €740 million.

Overview of images

Images may only be used for editorial purposes. They can be used free of charge if the source is given – ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.

BITZER Kühlmaschinenbau GmbH

Peter-Schaufler-Platz 1

71065 Sindelfingen

Telefon: +49 7031 932-0

Telefax: +49 7031 932-147

http://www.bitzer.de

Head of Public Relations

Telefon: +49 (7031) 932-4327

Fax: +49 (7031) 932543-70

E-Mail: patrick.koops@bitzer.de

![]()