Lyko`s leading market position online and their 38 wholly-owned retail stores produces a continuous, rapid growth in the current markets in Sweden and Norway. To be able to handle this strong growth, strategy for geographic expansion, a large number of articles and to maintain a high service level towards their customers were the reasons for Lyko to increase efficiency of their warehouse operations.

Lyko has announced that it will secure their future in warehousing by cooperating with one of the world’s leading suppliers of logistics solutions, SSI Schaefer.

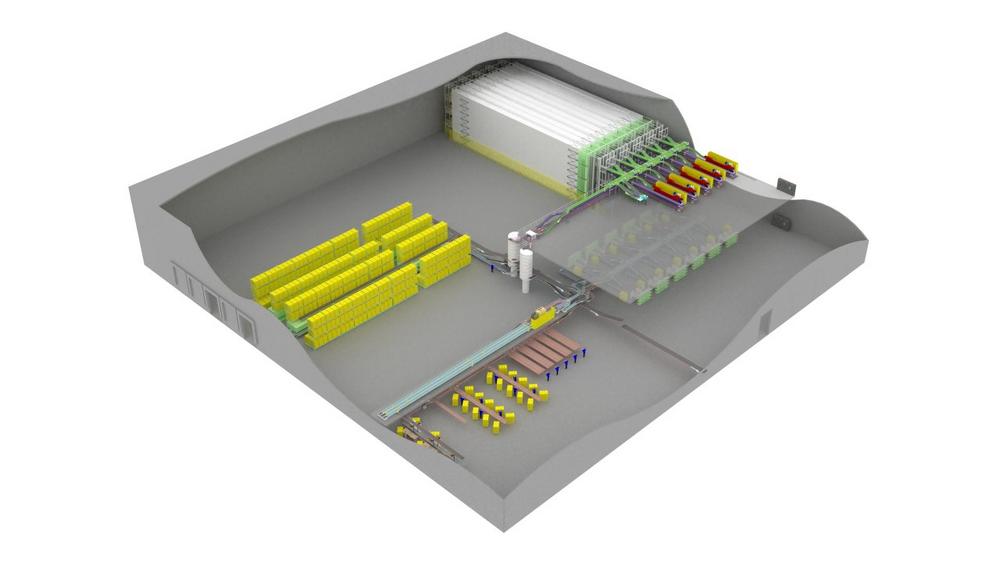

SSI Schaefer is going to realize a state-of-the-art warehouse for Lyko in a 10,000-square-meter facility including a 5-aisle shuttle system that will provide Lyko`s customers with around 50,000 different beauty products. Following the specific Nordic health & safety requirements, the goods-to-person-work stations will be installed accordingly to SSI Schaefer’s principle ergonomics@work!®. A bin and carton conveying system will connect the different warehouse areas efficiently. Furthermore, the WAMAS® logistics software from SSI Schaefer is going to coordinate the transparent warehouse processes.

Partnering with SSI Schaefer enables Lyko to increase significantly their productivity and storage capacity, improve picking performance and produce overall operational simplicity with consistent and streamlined warehousing processes.

Lyko`s Logistics & Purchasing Officer, Anna Persson explains: “SSI Schaefer served us with a strong intralogistics concept that offers a great flexibility. This together with excellent team work and cooperation were the main reasons that we choose SSI Schaefer as the system supplier for our new logistics center in Vansbro”.

The system is scheduled to go live in the beginning of 2020.

The SSI Schaefer Group is the world’s leading provider of modular warehousing and logistics solutions. It employs approximately 10,500 people at its group headquarters in Neunkirchen (Germany), at more than ten domestic and international production sites, and at approximately 70 worldwide operative subsidiaries. Across six continents, SSI Schaefer develops and implements innovative industry-specific answers to its customers‘ unique challenges. As a result, it plays a key role in shaping the future of intralogistics.

SSI Schaefer designs, develops and manufactures systems for warehouses, industrial plants, workshops and offices. Its portfolio includes manual and automated solutions for warehousing, conveying, picking and sorting, plus technologies for waste management and recycling. In addition, SSI Schaefer is now a leading provider of modular, regularly updated software for in-house material flows. Its IT team, with a headcount in excess of 1,100, develops high-performance applications, and provides customers with in-depth advice on the intelligent combination of software with intralogistics equipment. SSI Schaefer’s broad IT offering, including its own WAMAS® and SAP products, delivers seamless support for all warehouse and material flow management processes. Solutions from SSI Schaefer improve the productivity and efficiency of customer organizations – not least through the highly precise monitoring, visualization and analysis of operational metrics for proactive intralogistics management.

SSI Schaefer offers highly sophisticated, turnkey systems. As an international player, it can deliver one-stop solutions to all four corners of the earth. Its comprehensive portfolio encompasses design, planning, consulting, and customer-specific aftersales services and maintenance.

SSI SCHÄFER

Fritz-Schäfer-Strasse 20

57290 Neunkirchen / Siegerland

Telefon: +49 (2735) 70-1

Telefax: +49 (2735) 70-396

http://www.ssi-schaefer.de

Senior Global Communications Manager

Telefon: +49 (2735) 70-252

E-Mail: melanie.kaempf@ssi-schaefer.de