Thanks to nextLAP’s modular rack system, all kinds of order-picking processes can be easily digitized and automated. The "Smart Shelf" comprises IoT buttons with an LED screen, controller, and a screen or tablet. Shelves and storage areas are equipped with IIoT components and connected to the IP/1 platform, where all data are brought together and analyzed in real time.

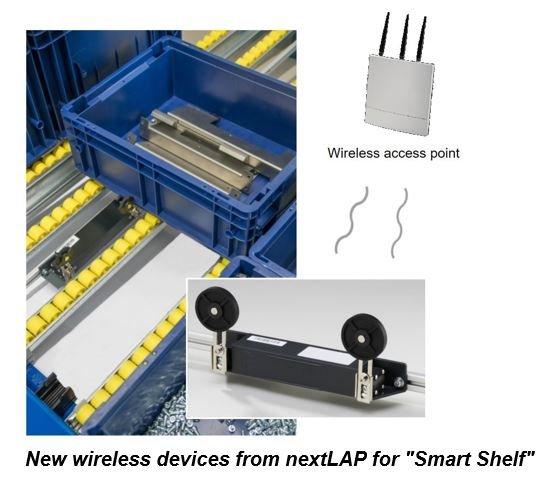

The new call button and roller rail sensor complement nextLAP’s wireless IIoT hardware portfolio. The wireless devices give the solutions the highest level of flexibility.

Wireless call button

The wireless call button enables material to be retrieved in real time ‒ directly and error-free ‒ at the press of a button, for instance for delivery to large load carriers (LLC). In addition, the call button sends selected information to the operator using a graphics-capable, high-contrast, yet energy-saving e-paper display. This applies, for instance, to order status, part numbers, or barcodes for material linking by scanner, allowing valuable information to be accessed and viewed easily and quickly.

Wireless roller rail sensor

The wireless roller rail sensor reliably registers the allocation status of roller conveyor positions – optionally from one or two container positions. If a container position is empty, a wireless message is sent that is directly translated to a material request. The flow rail concept allows a very flexible and simple connection to existing rail systems in flow racks.

Plug and play installation and easy connection to "Smart Shelf"

Both devices are plug and play components and 100% wireless. They are battery operated and maintenance free for 2 to 12 years. They communicate via the LoRa™ wireless network. This interference-resistant and energy-efficient technology allows ranges of up to 1000 m and ensures very high scalability up to several hundred devices that can be quickly and easily configured and connected to the nextLAP "Smart Shelf" app.

nextLAP Inc. was founded in late 2016 by former Audi managers and is based in Mountain View, California. Based on many years of profound industry experience in Production, Logistics & IT, the company developed the AI Production-Process-Platform IP/1. It brings together Engineering & Execution of any Manufacturing & Logistics processes, pushing towards the self-optimizing Factory of the Future that autonomously takes decisions based on AI. nextLAP’s SmartRack product family enables their customers to digitize Production and Logistics processes themselves. The big data obtained from the digitized processes is played back to the AI Production-Process-Platform IP/1. Using algorithms and artificial intelligence, improvement measures and alternative actions for decision making are generated real-time. All nextLAP’s solutions are leased "as a service" on a monthly basis with no fixed term; usage, maintenance and support are included. The company’s customers include leading premium automotive manufacturers in the USA and Germany. (www.nextlap.io)

nextLAP GmbH

Hofmannstraße 61

81379 München

Telefon: +49 (89) 999533725

http://www.nextlap.de

President

Telefon: +49 (89) 999533725

E-Mail: aziemke@nextlap.io

![]()