NAST 16 grinding table for grinding dust LIVE OPERATION

The NESTRO® NAST 16 grinding table with a 1,250 x 1,000 mm work surface is the smallest of the NAST series. The version exhibited features all the options available: Hydraulic table height adjustment, the pneumatic component clamping fixture that makes work much easier and the high-pressure extraction port for manual machine extraction and cleaning.

NZL 4 chipper LIVE OPERATION

NESTRO® shredders convert your disposal costs into energy gains – very quietly. With the NZL 4, the offset arrangement of the turning plates ensures low energy consumption while the low speed guarantees quiet operation. All wearing parts are designed to be very robust with a long lifespan. Large viewing windows allow visitors to clearly observe the always impressive chipping of the material (hardwood, softwood and chipboard) between the rotating knives on the rotor shaft and the fixed bed knife in the machine bed. Due to a window integrated in the floor of the 2nd level visitors can even risk a view into the shredder from above.

NE 250 deduster LIVE OPERATION

Both – the grinding table and the shredder – are connected to a NESTRO® deduster NE 250 featuring an operating volume flow of 5,600 m³/h to extract chips and dust. This type is the probably most sold power pack in the product family. It has nominal volume flow of 3,530 m³/h with corresponding negative pressure of 2,500 Pascal. The BG-certified deduster, BG-certified according to German legislation – can be set up in the immediate vicinity of the machine in the production hall and can also be used for filtering related materials such as plastic, leather, paper or other types of industrial dust.

NST 75 grinding bench for grinding dust LIVE OPERATION

The NESTRO® NST 75 grinding bench with an air volume of 7,500 m³/h removes dust from a 4,000 x 3,100 mm work surface with a separation rate of up to 95%. This ensures maximum freedom of movement, even with large work pieces. Trade fair visitors can see for themselves how grinding dust is effectively bound in the easy to clean filter elements by means of a low-turbulence directed airflow. Recirculating air operation reduces energy costs for the user and ensures a pleasant room atmosphere with minimal drafts in full compliance with the workplace directive.

PAINTLINE system for spray mist LIVE OPERATION

NESTRO® offers the PAINTLINE system in three performance classes with flow rates between 7,500 and 24,500 m³/h for the highest coating demands. The company is giving a live demonstration of medium performance class spray mist extraction at its exhibition stand. As solvents and paints sink to the ground due to their greater density, the paint particles are suctioned up in a continuous, low-draught airflow near the floor and then bound in the filter mats. The PAINTLINE systems allow a paint finish of consistently high quality even in continuous operation with extremely easy handling. NESTRO® custom-designs each of these systems based on the requirements of the customer and the space available. The individual systems are also scalable on demand thanks to the modular design.

NFHSU 11/11-35 filter house with NBP TH500 LIVE OPERATION

with spark detection & extinguishing system

The NESTRO® clean gas filter house allows large filter areas to fit in the tightest of spaces and material accumulated through the day to be stored temporarily. This system features a filter area of 305 m² and two fans for an air volume of 13,000 m³/h each. It allows visitors to experience live how wood chips and wood dust are filtered, collected and processed into briquettes with a diameter of 50 mm. Material is supplied to the filter house from the extraction of numerous HOMAG processing machines in the “HOMAG-City” in hall 14 through duct 1. The use of an active spark detection and extinguishing device can also be shown to the visitors.

Deduster NE 300 with briquetting press / NE 350 LIVE OPERATION

NESTRO® extracts dust and chips from processing machines typical for woodworking live in the workshop-concept-area of “HOMAG-City”. The type NE 300 with briquetting press NBP C150 turns waste material into energetically valuable briquettes. Its operating volume flow is 7,500 m³/h, the nominal volume flow is 5,085 m³/h with corresponding negative pressure of 2,400 Pascal. Since all NESTRO® dedusters work in clean gas operation – the fan comes after the filter – highest energy efficiencies and absolute dust tightness are guaranteed. The clean gas technology also reduces the risk of fire due to sparks since metal particles cannot get to the fan impeller. The residual dust content in the air discharged into the exhibition hall is less than 0.1 mg/m³.

The NE 350 deduster with an operating volume flow of 9,500 m³/h is the successful product family’s power pack. It has nominal volume flow of 6,927 m³/h with corresponding negative pressure of 2,750 Pascal, making it predestined for the extraction of CNC machines with high-speed processing or larger standard trains of machines in the wood industry where the simultaneous operation of various machines demands a high air volume.

Intermediate filter 9/4-30 with use of return air LIVE OPERATION

with spark detection & extinguishing system

A NESTRO® intermediate filter 9/4-30 with a construction height of more than 8 m is set up inside the “HOMAG-City” of the HOMAG stand at the western façade of hall 14. It provides extraction for additional HOMAG processing systems through the second duct. This filter well exemplifies the modular design with individual add-on elements. In practice the extraction performance can be freely chosen from 4,000 to 150,000 m³/h according to individual customer requirements. The 9/4-30 design used here has a filter area of 77 m² in each element. Three fans generate a flow rate of up to 45,000 m³/h. The outstanding visual quality of the filter is achieved thanks to its smooth surface due to consistent inside bending so typical for NESTRO®. Return air is discharged back into the exhibition hall, reducing the load on the air conditioning system and effectively improving the air quality (residual dust content < 0.1 mg/m³). This big size filter is equipped with a spark detection and extinguishing system, too.

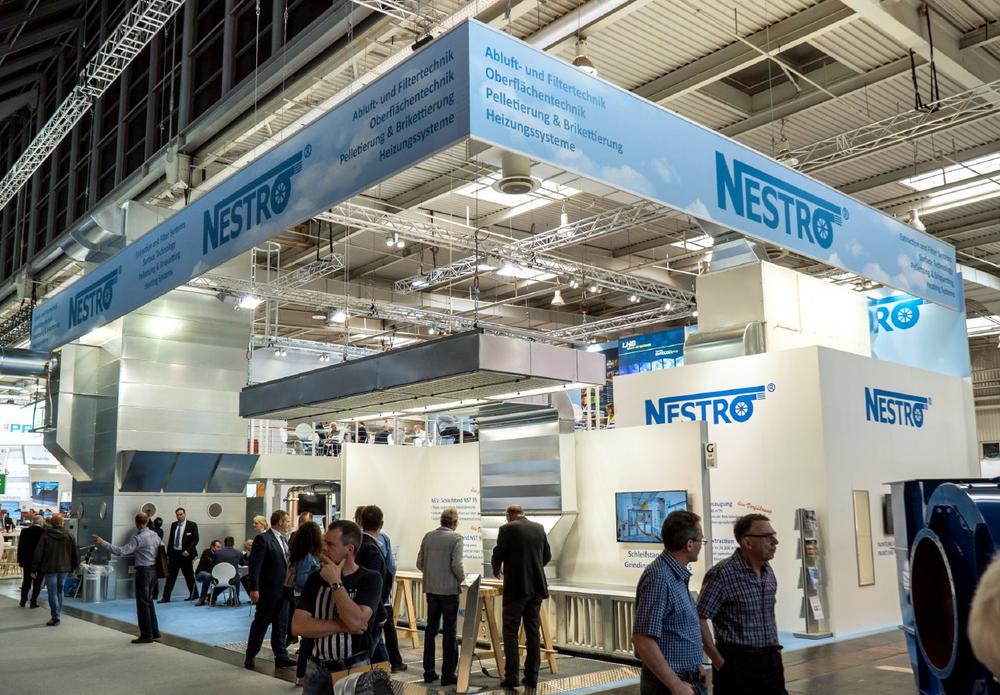

Founded in 1977, NESTRO® Lufttechnik GmbH is currently one of the large established manufacturers of products and systems for extraction and filter technology and for their downstream heating technology, for surface engineering and for sorting and disposal technology. About 180 employees develop and produce the equipment according to individual customer specifications at the three production sites in Germany, Poland and Hungary.

If you have any queries about this press release, please contact:

NESTRO® Lufttechnik GmbH, Paulus-Nettelnstroth-Platz, D-07619 Schkölen

Till Uhle, Director Marketing & Director Sales D|A|CH

Tel.: +49 (0)171 3003570 | E-Mail: t.uhle@nestro.de

Nestro Lufttechnik GmbH

Paulus Nettelnstroth-Platz

07619 Schkölen

Telefon: +49 (36694) 41-0

Telefax: +49 (36694) 41-260

http://www.nestro.de

Marketingleiter & Vertriebsleiter D|A|CH

Telefon: +49 (36694) 41-203

E-Mail: t.uhle@nestro.de