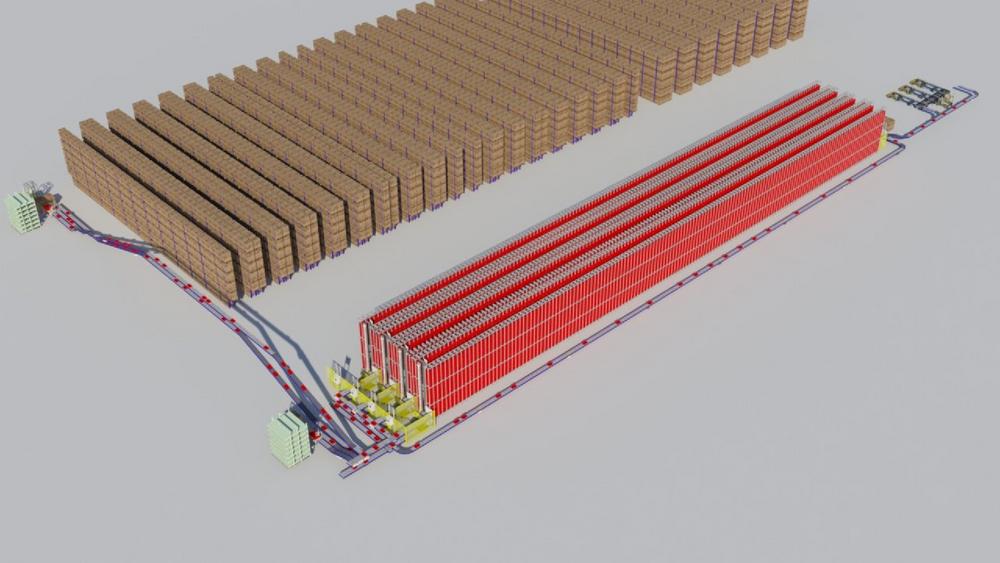

ZF is a global leader in driveline and chassis technology as well as active and passive safety technology. The company has a global workforce of 146,000 with approximately 230 locations in some 40 countries. ZF is one of the largest automotive suppliers worldwide and required a modern semi-automated system to meet the need of their in-plant production line. In order to improve working capacity, reduce manual power and lower error rate by using an empty space of their existing warehouse, a 4-aisle miniload and a 19-aisle VNA are equipped in the existing warehouse which will optimize the storage volume and improve picking efficiency. The project is intended to increase the degree of automation in the warehouse, and to increase process efficiency and performance.

For this purpose, SSI Schaefer will install a pallet conveying system to transport the spare parts on pallets to two different storage areas. The pallets are transported to the VNA storage area automatically by 12 VNA forklift trucks which is operated by the logistics software SAP. Then it goes to the existing production line. Or the full pallet will be transported to the depalletizing robot system. After decanting, the bins are moved on the bin conveying system to the miniload with 56,400 bin storage locations for storage. 4 Schaefer Miniload Cranes (SMC) with a turnover performance of 430 totes per hour take care of storage and retrieval. After receiving the instruction from SAP, totes will be transported to the picking area. The system is perfected by the powerful logistics software WAMAS® by SSI Schaefer to control and monitor warehouse operations.

The project is in progress now – go-live is scheduled for August 2019.

The SSI Schaefer Group is the world’s leading provider of modular warehousing and logistics solutions. It employs approximately 10,500 people at its group headquarters in Neunkirchen (Germany), at eight domestic and international production sites, and at approximately 70 worldwide operative subsidiaries. Across six continents, SSI Schaefer develops and implements innovative industry-specific answers to its customers’ unique challenges. As a result, it plays a key role in shaping the future of intralogistics.

SSI Schaefer designs, develops and manufactures systems for warehouses, industrial plants, workshops and offices. Its portfolio includes manual and automated solutions for warehousing, conveying, picking and sorting, plus technologies for waste management and recycling. In addition, SSI Schaefer is now a leading provider of modular, regularly updated software for in-house material flows. Its IT team, with a headcount in excess of 1,100, develops high-performance applications, and provides customers with in-depth advice on the intelligent combination of software with intralogistics equipment. SSI Schaefer’s broad IT offering, including its own WAMAS® and SAP products, delivers seamless support for all warehouse and material flow management processes. Solutions from SSI Schaefer improve the productivity and efficiency of customer organizations – not least through the highly precise monitoring, visualization and analysis of operational metrics for proactive intralogistics management.

SSI Schaefer offers highly sophisticated, turnkey systems. As an international player, it can deliver one-stop solutions to all four corners of the earth. Its comprehensive portfolio encompasses design, planning, consulting, and customer-specific aftersales services and maintenance.

SSI SCHÄFER

Fritz-Schäfer-Strasse 20

57290 Neunkirchen / Siegerland

Telefon: +49 (2735) 70-1

Telefax: +49 (2735) 70-396

http://www.ssi-schaefer.de

Senior Global Communications Manager

Telefon: +49 (2735) 70-252

Fax: +49 (2735) 70-382

E-Mail: melanie.kaempf@ssi-schaefer.de