- Positive leach recovery results reported from Aachen TM pilot scale testwork

- AachenTM is a relatively simple, proven process being used by a number of successful gold producers globally and specifically in Africa. These operations have consistently demonstrated an uplift in gold recoveries with AachenTM

- AachenTM results on Namdini flotation concentrate indicates the following potential improvements:

– increased gold recovery (Table 1)

– coarser regrind size compared with the current flowsheet

– reduced power consumption (ie lower installed power requirements and Opex)

– improved mass transfer of oxygen and reactivity of reagents

– reduced reagent consumption leading to reduced operating costs

– expected reduction of both Capex and in particular, Opex

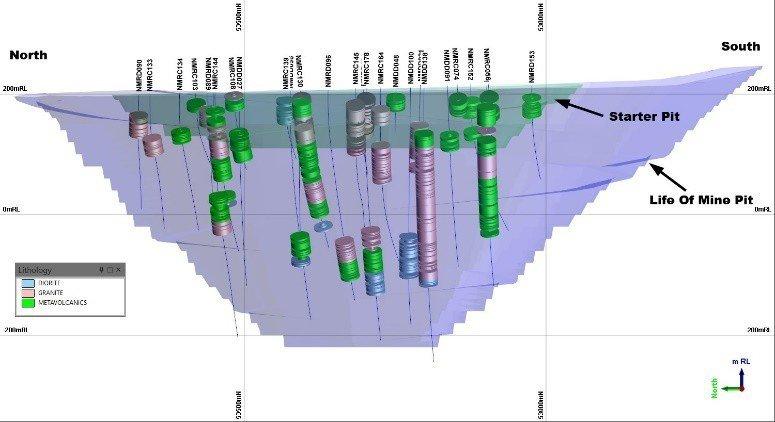

- Cardinal has already tested 4,447 kg (>4 tonnes) comprising 7 pilot scale composites from 47 drill holes (Table 2) across the entire deposit. Cardinal is finalizing the testwork programme with a further 2,310 kg (>2 tonnes) of samples from an additional 24 drill holes

- Final AachenTM testwork is in progress to further support the results received to date for potential inclusion into the Namdini Feasibility Study

Peter Lotz, Gold Process & Environment Manager, Maelgwyn Mineral Services Africa, stated:

“Our AachenTM process is currently deployed at 9 different mine sites in 6 countries, with the longest service life of over 10 years on one of the largest bullion producers within the African continent.

“We’ve seen our process increase gold recoveries between 2% and 19% in gold producing operations. Former Randgold Resources (now Barrick), a major client of MMS, is using AachenTM equipment at its Loulo and Morila mines in Mali, at its Tongon operation in Côte d’Ivoire, and at the Kibali gold mine in the Democratic Republic of Congo.

“We look forward to our continuing work with Cardinal in this regard”.

Cardinal’s Chief Executive Officer / Managing Director, Archie Koimtsidis stated:

“These highly encouraging results from the metallurgical optimisation programme are potentially an opportunity to further enhance the Namdini project financial outcomes and should be incorporated into the process flowsheet being designed by Lycopodium.

“The metallurgical optimisation test results recently received and evaluated show promising recovery, capital and operating cost improvements, which can be achieved over and above the current outcomes justifying incorporation into the Feasibility Study”.

Cardinal has recently completed its current testwork to consider the introduction of an AachenTMsystem into the Namdini process flow sheet which is being established by Lycopodium. The testwork has been completed at the Maelgwyn Mineral Services Africa (MMSA) metallurgical laboratory in South Africa.

The base premise of the process is to scour the mineral surfaces and maximise oxygen transfer to the ore slurry prior to leaching, which enhances leach kinetics, resulting in improved recovery of gold. It is a relatively simple, proven process already being used at 9 gold producing mines.

In addition to a potential increase in gold recovery (and therefore a potential uplift to annual gold production rates), there are typically power and reagent savings (Opex savings) and installed power requirements (Capex savings) that can be realised.

Testwork on integrating the AachenTM process into the Namdini flowsheet demonstrated potential to increase recoveries for the Life of Mine study and also suggested an increase in the grind size from sub 10 microns (µm) into the coarser range of 20 to 45 microns (µm) for certain lithologies. Further testwork is ongoing to consider the optimal grind size and target recovery, with detailed cost/benefit analysis underway as part of the programme.

The AachenTM process has also been successfully used for cyanide destruction, post leach circuit, which will also be analysed for further Opex and Capex savings.

Next Steps

As a result of the positive leach results which are expected to enhance Namdini Project economics, further testwork samples have been submitted. All aspects of the Feasibility Study are on track for delivery this quarter, however, Cardinal is reverting to the original Q3 – 2019 Feasibility Study publication timeline in respect of the Company’s flagship Namdini Gold Project in Ghana so that final testwork results from the AachenTM process can be incorporated.

Study Manager Lycopodium continues to accelerate the full integration of all project disciplines and to coordinate the efforts of our other study partners.

Lycopodium is a highly respected mining services company with over 25 years’ global experience in the minerals industry, designing and building large-scale mines, processing plants and associated infrastructure, particularly in Africa and West Africa.

ABOUT MAELGWYN – AachenTM Process

Maelgwyn Mineral Services (MMS) is a world leader in the development and implementation of innovative cost- effective technologies and processes in the field of mineral, chemical and waste processing. It has had many patents granted and has won a number of national innovation awards for its process.

The AachenTM process is one of Maelgwyn’s primary business metallurgical technologies which can be tested at their fully certified and commercial laboratory in South Africa. The AachenTM process can be tested at bench and pilot scale in this laboratory.

The AachenTM process uses a pipe shear device designed to improve oxidation of slurries using oxygen. It uses a slot aerator to introduce micron-sized (200µm) oxygen bubbles into the device which has different chambers separated by orifice plates creating a highly efficient contact of oxygen to the slurry. The equipment is especially efficient for high- rate oxidation of sulphides which is ideal for Namdini’s ore since the gold is particulate and occurs as free gold, in fractures in pyrite or in pyrite grains.

The objective is to increase efficient utilisation of the oxygen and as a consequence of the significant increase in real-time oxidation it could allow grind sizes to be coarser thus reducing overall power and reagent costs. The device contains no moving parts, and is designed to withstand erosive effects of mineral slurries.

MMS have commissioned more than 60 of the AachenTM units on the African continent, working with several high-profile mining companies across several jurisdictions.

Former Randgold Resources (now Barrick), a major client of MMS, is using AachenTM oxidation technology at its Loulo and Morila mines, in Mali, at its Tongon operation, in Côte d’Ivoire, and at the Kibali gold mine, in the Democratic Republic of Congo.

MMS has also provided the process to Liberian gold miner Avesoro Resources’ (formerly Aureus Mining’s) New Liberty gold mine and to South African gold miner Pan African Resources at its Barberton Mines operation, where the Aachen units are used in the cyanidation circuit and are also used to support the cyanide detoxification processes.

MMSA is also working on several tailings storage facility reclamation projects in South Africa and aims to use Aachen oxidation technology in the various reclamation processes.

On-site Due Diligence

Cardinal Resources’ management undertook a due diligence review of the AachenTM process in March 2019. The due diligence review included a site visit to the Maelgwyn laboratory facility in Northcliff South Africa followed by a site inspection of two AachenTM devices installed at a gold mine operating in Southern Africa.

A summary of observations made during the site visit is highlighted below:

- There are 63 AachenTM units currently employed at 9 sites in Africa.

- Scale up from laboratory to full production has generally shown greater improvements. Generally, a 5% recovery improvement in the laboratory can translate into 7 or 8% in full-scale operation.

- Slurry input to the unit is generally ~2 m/s and the velocity through the contact zone is ~10 m/s. Oxygen is introduced with micron-sized bubbles (200µm), with + 10 m/s velocity.

- Maelgwyn expect 4,000 to 5,000 hours service between maintenance intervals based on operational experience.

In general terms, high shearing of slurry particles and high velocity of oxygen, results in improved kinetics by scouring the particle surfaces and accelerating the oxidation of the sulphide species which then allows for less residence time and less reagent requirements within the leaching circuit.

AachenTM Testwork Procedure

The scope of work for the pilot scale experiments is outlined in the diagram below. The seven (7) bulk composite sample ID’s were sequentially processed via primary milling, to a grind specification of 50% passing 212 μm, followed by Knelson gravity separation and secondary milling to 80% passing 106 μm. The milled gravity tails were subjected to froth flotation to generate concentrate for the subsequent AachenTM testwork series.

Summary of the AachenTM testwork results on Namdini samples:

Maelgwyn’s AachenTM Process is showing encouraging results on a number of fronts with the most significant being:

- Recovery improvement

- Leach kinetics

- Potential increase in grind size without compromising recovery

- Power and reagent consumption reduction, specifically oxygen and cyanide

All the above points could result in project economic benefits by reducing OPEX and CAPEX whilst improving gold recovery which has provided a clear path forward for Cardinal and the Aachen™process.

Position of Aachen™ equipment within Namdini Flowsheet

AachenTM will be deployed after the flotation concentrate regrind circuit as indicated in Figure 6. The process throughput is relatively small since only flotation concentrate is treated through the device.

ABOUT CARDINAL

Cardinal Resources Limited (ASX/TSX: CDV) is a West African gold exploration and development Company that holds interests in tenements within Ghana, West Africa.

The Company is focused on the development of the Namdini Project with a gold Ore Reserve of 5.1Moz (0.4 Moz Proved and 4.7 Moz Probable) and a soon to be completed Feasibility Study.

Exploration programmes are also underway at the Company’s Bolgatanga (Northern Ghana) and Subranum (Southern Ghana) Projects.

Cardinal confirms that it is not aware of any new information or data that materially affects the information included in its announcement of the Ore Reserve of 3 April 2019. All material assumptions and technical parameters underpinning this estimate continue to apply and have not materially changed.

Swiss Resource Capital AG

Poststrasse 1

CH9100 Herisau

Telefon: +41 (71) 354-8501

Telefax: +41 (71) 560-4271

http://www.resource-capital.ch

CEO

Telefon: +41 (71) 3548501

E-Mail: js@resource-capital.ch