Highly efficient compressors, effective compressed air treatment systems, smart engineering and intelligent services are just a few of the highlights that reveal the modern face of needs-based compressed air production, combined with good planning.

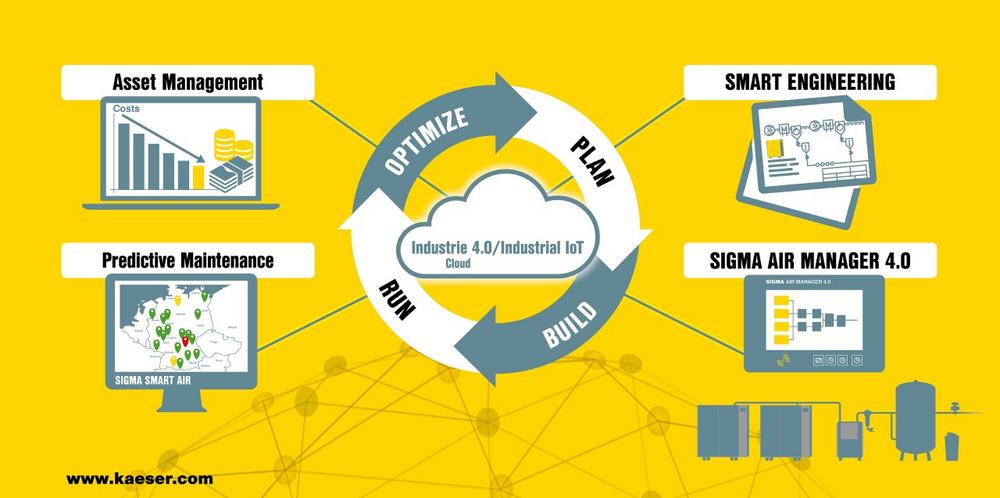

We are offering a glimpse of the future. Smart engineering station simulations make it possible to see a fully operational compressed air station before it has even been built. Moreover, the new Sigma Smart Air shows how maintenance is carried out in the age of Industrie 4.0: with the comprehensive service package, Sigma Smart Air offers a combination of remote diagnosis and data-based, predictive maintenance that saves the user both time and money, whilst ensuring the availability of the compressed air supply. The basis of these forward-looking concepts is the Sigma Air Manager 4.0 in combination with the Sigma Network. The powerful, closed network and the intelligent controller are perfectly coordinated cornerstones of Kaeser’s Industrie 4.0 package.

Operating efficiency is of key importance at Kaeser on every level, together with a responsible approach to resource conservation. Therefore, all variable-speed rotary screw compressors are being systematically equipped with a synchronous reluctance motor, which boasts considerably lower losses – and, in turn, greater efficiency – in the crucial partial-load range, compared to asynchronous motors. Following in the footsteps of the ASD series, the CSD/CSDX series is the next to feature efficiency improvements of up to 10%, with flow rates ranging from 1.1 to 17.5 m³/min., paving the way for minimal energy costs.

If oil-free compressed generation air is required, FSG series rotary screw compressors provide the perfect solution in combination with i.HOC rotation dryers: not only highly efficient and cost-effective, they also achieve stable pressure dew points to minus 30 degrees Celsius.

With a drive power of 7 to 45 kW, Kaeser’s innovative boosters are the powerhouses of choice when higher pressure compressed air is called for (up to 45 bar). Compact and space-saving, with low-noise, vibration-free performance, they are ideal all-in-one booster solutions and are also available as variable-speed versions.

The needs of trades and workshops are also well catered for at Kaeser Kompressoren, with a compressed air solution for every application. The new i.Comp reciprocating compressors are robust, powerful, compact, maintenance-friendly, efficient – the list goes on. The centrepiece is the new drive concept, which offers a host of advantages. Every reciprocating compressor model delivers exactly the output required and can be infinitely adjusted to suit actual compressed air demand. Manufactured to the very highest industrial quality standards for which Kaeser is world-renowned, i.Comp models are available as portable models and as space-saving i.Comp tower compact stations – a completely new compressed air supply concept that was specially developed for workshops.

Kaeser can be found in Hall 12, stand A16.

KAESER KOMPRESSOREN SE

Carl-Kaeser-Str. 26

96450 Coburg

Telefon: +49 (9561) 640-0

Telefax: +49 (9561) 640-130

http://www.kaeser.com

Pressestelle

Telefon: +49 (9561) 640-452

Fax: +49 (9561) 640-129

E-Mail: daniela.koehler@kaeser.com

![]()