Cooperation with Phoenix Contact

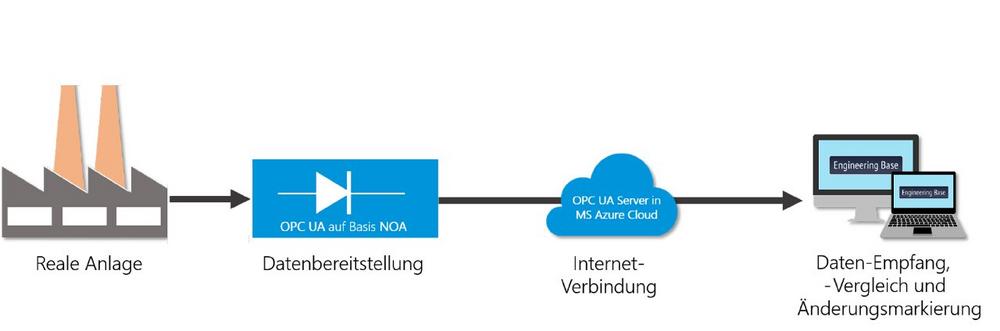

Aucotec’s platform Engineering Base (EB) is the single source of truth for the mapping of the plant. EB’s cross-disciplinary data model detects via OPC UA when a device in the plant is changed or replaced. The new "Hart-IP Gateway" from Phoenix Contact, which can be easily connected to a top hat rail in the field distributor and "translates" the usual Hart signals of the devices into OPC UA, enables all field devices that were not previously OPC UA-capable to communicate via this protocol.

Aucotec and Phoenix Contact will present this solution together for the first time at the Namur Annual General Meeting at the beginning of November. It will then be presented to a wider audience at the SPS shortly afterwards. In a live demonstration at the Aucotec stand, visitors can watch how a device replacement is reflected in the entire plant documentation in no time at all. EB’s object orientation, web capability and OPC UA understanding make this possible, as do the gateways, which save expensive remote I/Os or the replacement of functional devices just because they do not have an OPC UA interface.

Live and automatic: current "health status"

Brownfield operators can thus not only be sure that they have the current status of their plants at hand at all times. EB is also able to map the Namur recommendation NE 107 to any object in any view, from graphic to list. This makes it possible to identify each individual "health status", which shows, for example, whether a device is functioning properly, whether there is a fault or maintenance is required.

It is not documents that need to be updated, but data!

"All this information is available in EB directly on the object. EB is data-centred, not file-based and therefore does not update just any document, but the complete data model of the digital twin," emphasizes Martin Imbusch, Product Manager at Aucotec. This principle is becoming increasingly important because, according to a VDMA/PwC study on large-scale plant construction, the proportion of data-controlled service models will triple by 2025.

The digital upgrading of brownfield plants and their documentation, developed together with Phoenix Contact, is a logical next step for Aucotec. At the Namur Annual General Meeting in 2018, Aucotec, together with the ifak Institute of the University of Magdeburg and the Höchst IGR, demonstrated for the first time ever that and how a plant can communicate with its digital twin using a test plant. Now it has become a workable solution for plants in real-time operation.

Aucotec at the SPS: Hall 6, Stand 110

Aucotec AG has more than 30 years‘ experience in the development of engineering software designed for use throughout the service life of machinery, plant equipment and mobile systems. Available solutions range from flow diagrams and process-control/electrical technology for large-scale plant systems to modular on-board power supply units designed for the automotive industry. Software supplied by Aucotec is currently in operation throughout the world. Hanover-based Aucotec also operates six further sites in its home country of Germany, along with subsidiaries in China, South Korea, France, the UK, Italy, Austria, Poland, Sweden and the United States, while counting on a global network of partners to supply local support throughout the world.

AUCOTEC AG – EN

Hannoversche Straße 105

30916 Isernhagen

Telefon: +49 (511) 6103-0

Telefax: +49 (511) 614074

http://www.aucotec.com

Presse & Öffentlichkeitsarbeit

Telefon: +49 (511) 6103-186

Fax: +49 (511) 614074

E-Mail: jki@aucotec.com

![]()