Demands on the particulate cleanliness of parts for mechatronic assemblies such as, e.g., hydraulic or pneumatic systems, as well as pump housings and motor housings are becoming ever more stringent. Specifications calling for zero particles larger than 400 µm or even less are now commonplace. Reliable deburring is a basic prerequisite for meeting such requirements.

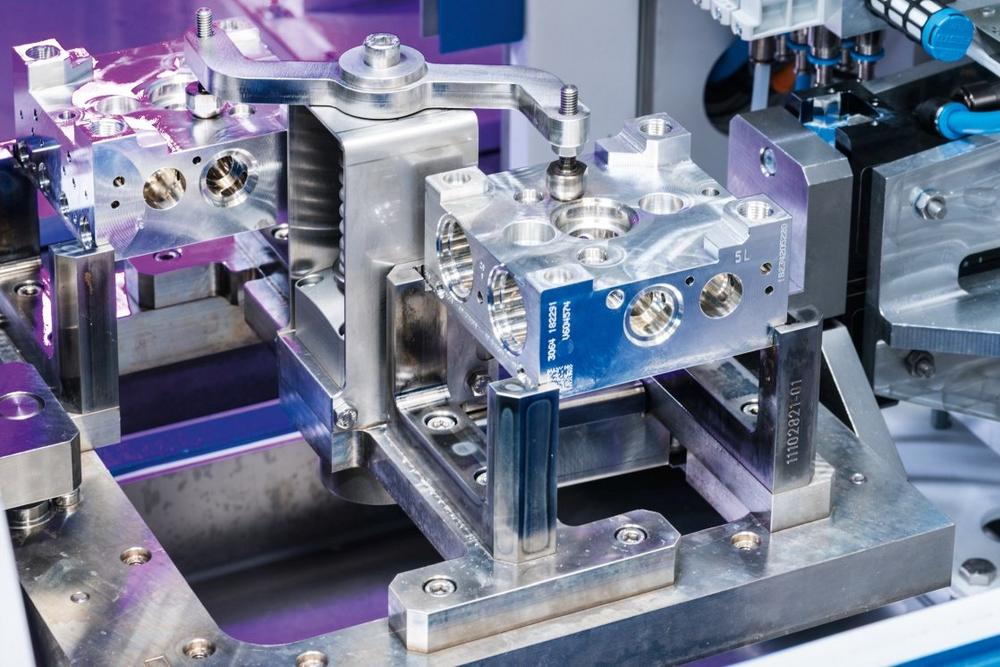

At this year’s parts2clean (hall 7, booth B31) in Stuttgart, Ecoclean will present its innovative EcoCvelox system – a world first that combines 5-axis high-pressure deburring with various part cleaning and drying processes in an efficient and space-saving machine design. The system can be configured and expanded to meet specific process needs and allows parts measuring up to 200 x 200 x 200 mm to be deburred within a 15-second cycle per pallet. For rapid and easy programming of the high-pressure deburring step, whether performed with a single spindle or using a high-pressure turret carrying up to five tools, a CAD/CAM interface has been integrated. This feature, along with the highly dynamic part handling system, allows process workflows for new workpieces to be implemented in a minimum of time. For cleaning and drying, respectively, the parts can be subjected to injection flood washing, spraying, selective rinsing and ultrasonic processes plus high-speed air blowing and vacuum drying. Depending on the task at hand, the EcoCvelox can be combined and interlinked with other products from this manufacturer’s range such as, e.g., a solvent-based system for precleaning oily parts. Fine-cleaning can afterwards be performed using, for instance, the water-based EcoCwave cleaning system that will likewise be on exhibit at this trade fair.

Where very exacting cleanliness requirements need to be fulfilled reliably and efficiently in processing parts for the optical, medical equipment, toolmaking and high-tech or high-purity industries, the multi-stage ultrasonic cleaning systems supplied by UCM AG – an SBS Ecoclean Group company – are the right solution. Thanks to diverse equipment and engineering details and optimum design and process development, these systems set new standards in fine cleaning and ultra-fine final cleaning technology.

The digitalization of cleaning processes is another field for which Ecoclean will be presenting effective solutions at parts2clean. This capability can provide enhanced production planning and hence, increased productivity, in addition to full end-to-end documentation, whether lot- or part-specific, of plant and process conditions and much more.

Forward-looking service solutions, including the use of augmented reality for maintenance and repair work, round out the offering at Ecoclean’s trade fair booth. In addition, experienced customer service personnel staffing the "service island" will provide information on subjects such as predictive maintenance, tailor-made service concepts, customer staff training, and equipment modernization and adaptation.

Ecoclean GmbH at parts2clean (22 – 24 October 2019) in Stuttgart: Hall 7, Stand B31

The SBS Ecoclean Group (formerly Dürr Ecoclean) develops, produces and markets forward-looking machinery, systems and services for industrial part cleaning and surface treatment applications. Its globally leading solutions help companies around the world in conducting efficient and sustainable manufacturing to high quality standards. The client base comes from the automotive industry and its suppliers in addition to a broad range of market sectors ranging from medical equipment, micro technology and precision devices through mechanical and optical engineering to power systems and aircraft industry. Ecoclean’s success is based on innovation, cutting-edge technology, sustainability, closeness to the customer, diversity and respect. The Group employs a workforce of approx. 900 at its 12 sites in nine countries worldwide.

Ecoclean GmbH

Mühlenstraße 12

70794 Filderstadt

Telefon: +49 (711) 7006-0

Telefax: +49 711 7006-148

http://www.ecoclean-group.net

Journalistin (DJV) und Texterin

Telefon: +49 (711) 854085

E-Mail: Doris.Schulz@PresseTextSchulz.De

![]()