There is a difference between adhesives that form direct bonds on the skin and those that are used as laminating adhesives and do not come into direct contact with human skin. Adhesives that are allowed to come into direct contact with skin are used in the manufacture of plasters, such as artimelt M11.1506, which is ideal for contact with sensitive skin. Surgery drapes are often made up of multiple layers. The individual layers are stuck together using a laminating adhesive such as artimelt M12.317. Sometimes, a self-adhesive edge strip is applied to ensure that the drape can be affixed to the patient’s skin. artimelt M11.1566 is very well suited for this purpose.

Laminating adhesives are also used in the manufacture of ECG electrodes in order to ensure that the individual components remain reliably and constantly stuck together. At room temperature, these adhesives are dry and non-sticky. However, once they are warmed up, they become soft and their adhesive properties are awakened. The adhesive subsequently forms a bond to the substrate when pressure is applied. These adhesives are different from pressure-sensitive adhesives (PSA) that are constantly sticky and must be covered with a release liner.

During the sterilization process, the question of “what happens to the adhesive?!” is always asked. Does the form, color, smell, etc. of the adhesive change? artimelt carried out a comprehensive study and subjected selected artimelt adhesives to individual sterilization methods:

- Ethylene oxide sterilization (EtO)

- Gamma radiation

- X-ray radiation

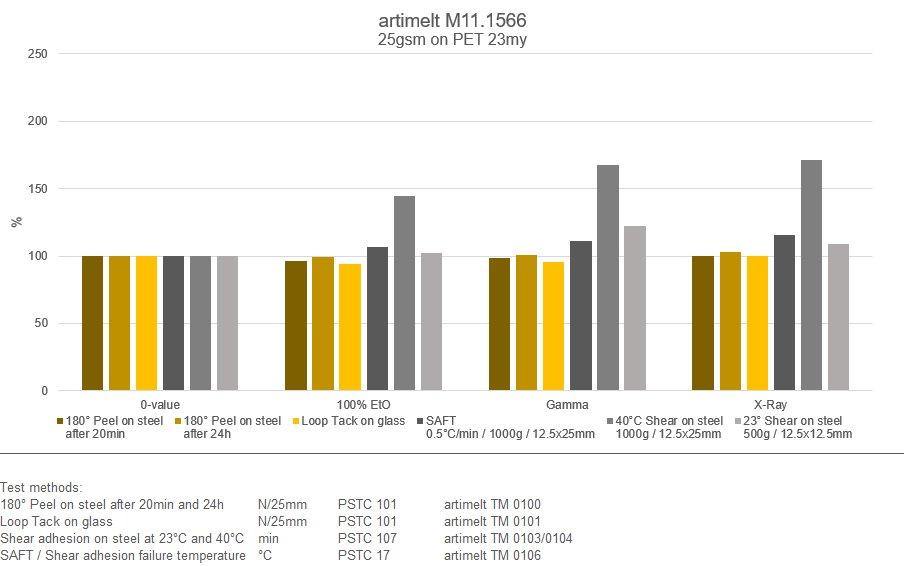

The results from the investigation into artimelt M11.1566 – an adhesive for plasters and tapes – are listed as an example.

The chart shows the change in the adhesion and cohesion values following sterilization.

The “0-value” values show the adhesive properties prior to sterilization. Depending on the method used, barely any differences were recorded. This means that the adhesive almost retains its original properties. The sterilization process can even be said to have positive effects on the adhesive, as the cohesion – and therefore the internal strength – increase and the adhesion remains the same! Based on this study, we can say that the artimelt adhesives are ideally suited for sterilization.

In addition to high-quality raw materials, extensive specialist knowledge is also required to manufacture premium products for medical applications. artimelt has over 30 years‘ experience in the development and manufacture of adhesives for medical applications. artimelt adhesives form a secure bond and can still be removed from human skin without causing any pain or leaving any residue behind. In addition, the special formulations are breathable and thus prevent the skin from macerating. It comes as no surprise that artimelt adhesives are tested for their suitability for coming into contact with human skin and are classified as being harmless.

artimelt meets the high standards demanded in the heavily regulated market for medical and sterile applications. We also offer the right products for related markets in which there are high safety standards, such as in the foodstuffs and cosmetics industries. artimelt customers are not only able to choose products from the existing range – artimelt can work in close coordination with customers to develop tailor-made adhesive solutions that are a perfect fit with their processing methods and fields of application.

If you have any questions related to adhesives for use in a sterile environment, please do not hesitate to contact us. The artimelt team would be delighted to hear from you.

artimelt AG

Wassermatte 1

CH6210 Sursee

Telefon: +41 (41) 92605-00

Telefax: +41 (41) 92605-29

http://artimelt.com

Business Operations

Telefon: +41 (41) 92605-32

E-Mail: patrizia.fussen@artimelt.com

![]()