In all industrial sectors, component cleaning plays a major role when it comes to product quality and added value. If equipment does not function according to plan or if a cleaning system suffers unscheduled downtime, this usually has negative consequences, such as the return of faulty goods or disruptions to production or delivery processes. The result is increased unit costs, which are detrimental to profitability and competitiveness.

Optimized process quality and equipment availability

If process quality and the availability of the cleaning system are always kept at an optimal level, related costs and image damage can largely be avoided. Ecoclean has developed a comprehensive portfolio of services and products for this purpose. The services offered range from advice during the planning of a new system to ensuring the availability of the system throughout its entire service life, as well as assistance in optimizing cleaning processes, adapting the system to new requirements and improving energy efficiency. In the global service network of the equipment manufacturer with its locations and agencies, more than 125 customer service employees take care of around 5,000 installed systems.

Individually combinable services

Regular maintenance is key to ensuring consistently high process quality and system availability. To meet the wide-ranging requirements and wishes of equipment users, regular service agreements can be tailored to respective needs. In this way, maintenance can be carried out during a ‘controlled production downtime’ when it suits and at minimized cost.

If a malfunction needs to be rectified quickly, Ecoclean customer service is available 24 hours a day, seven days a week. Remote service enables experts with in-depth process and system knowledge to access equipment remotely, analyse the cause and help solve the problem at a time arranged with the user. Of course, faults can only be rectified fast if the equipment user has the necessary spare and wear parts in stock. For this reason, the customer service staff also recommend which spare parts should be procured for the respective system. If worst comes to worst, they make sure that the required spare and wear parts are shipped quickly anywhere in the world.

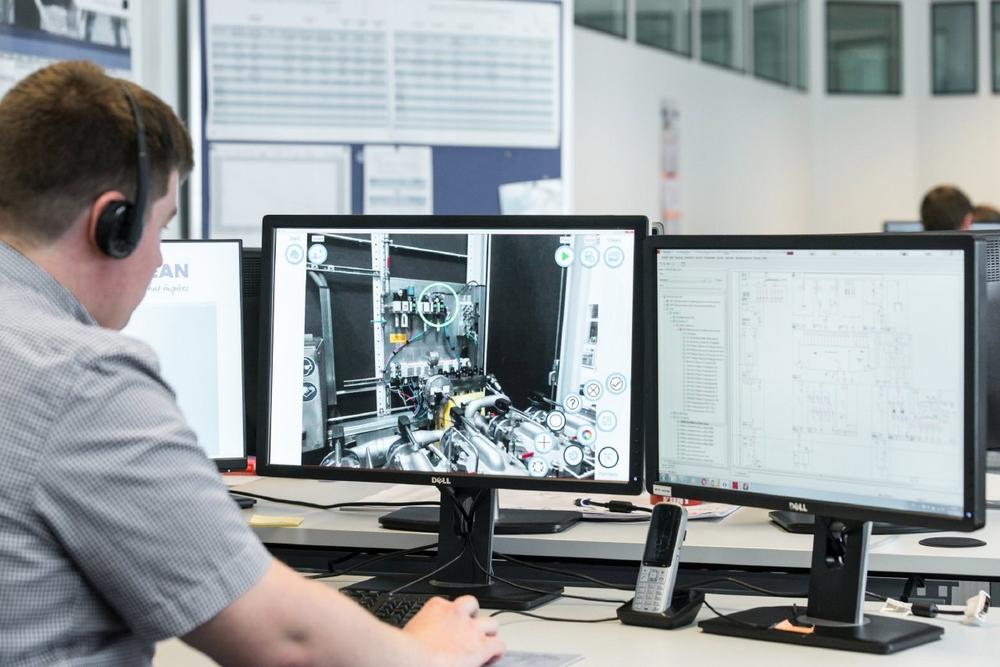

New service app for fast and efficient communication

The new service app for IOS and Android will be available from January 2020 and permit two-way exchange between equipment users and Ecoclean customer service employees via video call and chat functions. The information and instructions required for troubleshooting or system maintenance can be transmitted directly by smartphone. Using the phone’s camera, helpdesk employees can follow the work closely and intervene immediately if something goes ‘wrong’. The normal phone and chat function can be used to answer questions immediately or to clarify instructions. This state-of-the-art form of service support minimizes the need for long and costly trips. It not only reduces equipment downtimes but also CO2 emissions.

The SBS Ecoclean Group develops, produces and markets forward-looking machinery, systems and services for industrial part cleaning and surface treatment applications. Its globally leading solutions help companies around the world in conducting efficient and sustainable manufacturing to high quality standards. The client base comes from the automotive industry and its suppliers in addition to a broad range of market sectors ranging from medical equipment, micro technology and precision devices through mechanical and optical engineering to power systems and aircraft industry. Ecoclean’s success is based on innovation, cutting-edge technology, sustainability, closeness to the customer, diversity and respect. The Group employs a workforce of approx. 900 at its 12 sites in nine countries worldwide.

Ecoclean GmbH

Mühlenstraße 12

70794 Filderstadt

Telefon: +49 (711) 7006-0

Telefax: +49 711 7006-148

http://www.ecoclean-group.net

Journalistin (DJV) und Texterin

Telefon: +49 (711) 854085

E-Mail: Doris.Schulz@PresseTextSchulz.De

![]()