BITZER has been a pioneer for new products with a unique CO2 balance for many years – especially with regard to energy efficiency, particularly low-GWP-refrigerants and user-friendliness. For decades, the traditional company has been developing refrigeration and air conditioning components for refrigerants such as CO2, ammonia and from the A2L group as well as new methods of capacity control. In recent years, the focus has been exclusively on the discussion about the refrigerants in use; now the industry will start re-focusing on the effects of the energy consumption of refrigeration plants. Therefore, the BITZER stand at EuroShop 2020 will include product highlights for CO2 as well as other intelligent components and A2L condensing units.

The specialist for refrigeration and air conditioning technology provides components for sustainable solutions – for natural and ultra-low-GWP refrigerants, efficiency improvements and with a high recycling capability. A holistic view of the CO2 balance of refrigeration systems and the taxation of CO2 emissions, not only from leaked refrigerants, requires new ideas. The experts from BITZER will be happy to discuss these at their EuroShop stand.

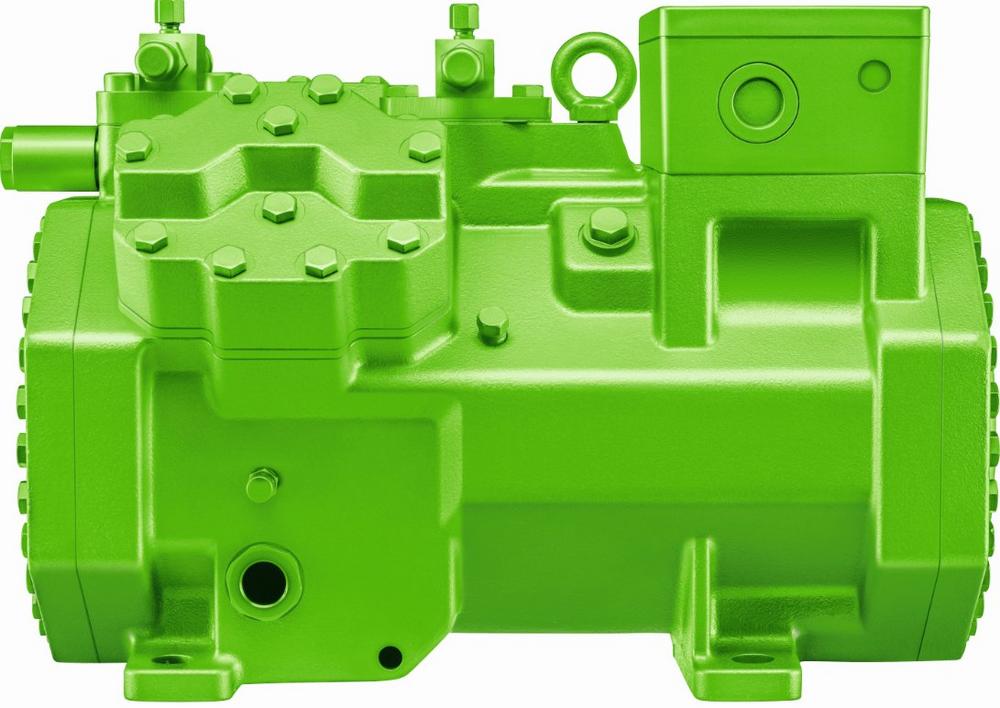

Reciprocating compressors: efficient progress

BITZER ECOLINE reciprocating compressors are highly energy-efficient both in full and part load and are designed for a very wide range of applications going beyond supermarket applications. One advantage of the series: it offers maximum freedom in the choice of refrigerant. Whether new low-GWP mixtures, HFO refrigerants such as R1234yf, R1234ze(E) or natural refrigerants – with BITZER reciprocating compressors, users find a suitable solution for every requirement. The ECOLINE series also includes the ME compressor series, which was especially designed for subcritical CO2 applications with high standstill pressures up to 100 bar. BITZER has now supplemented this series with two 6-cylinder models. With 54 m³/h and 64.9 m³/h delivery volume at 50 Hz, the two larger models are particularly suitable for large refrigeration systems in hypermarkets and distribution warehouses.

ECOLINE+, the latest reciprocating compressor series from BITZER, is available as 4- and 6-cylinder version for CO2 applications and is particularly suitable for supermarket applications. ECOLINE+ was developed with line start permanent magnet motors, which provide double efficiency benefits due to increased motor efficiency and thus reduced heat transfer into the refrigerant. This motor technology enables the compressors to achieve an up to 14 per cent higher SEPR (annual performance factor).

ECOLITE: flexible use for medium and low temperature refrigeration

The ECOLITE LHL3E and LHL5E condensing units open up a wide range of applications from 1.5 kW to 5 kW in the low temperature range and from 3.5 kW to 16 kW in the medium temperature range. One of their great advantages: Each of these models can be used for different applications and refrigerants. For the first time, BITZER is now also exhibiting ECOLITE in a version for low-GWP refrigerants of the A2L category at a trade fair – and thus a future-proof solution for refrigerants with a GWP below 150. The design of the condensing units ensures that their components are easily accessible and can be serviced quickly and easily if necessary. With all ECOLITE models, users enjoy the option of quick installation and commissioning thanks to the user-friendly controller with BEST software.

OS.95: efficient, powerful and universally applicable

With its energy-efficient OS.A95 screw compressor series, BITZER offers a climate-friendly and powerful solution especially in the field of ammonia applications for large cooling capacities. The wide application limit diagram of the series in combination with the automatic Vi adjustment allows the efficient use of OS.A95 in air conditioning, refrigeration and low temperature systems. The further developed rotor profiles and the generous flow cross-sections in the compressor also contribute to an efficient operation. Furthermore, the integrated IQ module simplifies compressor operation, control and monitoring. The series includes the universal models of the OSKA series for all applications and the OSNA series for specific low temperature applications.

■

As an independent specialist for refrigeration and air conditioning technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always considering highest possible energy efficiency and quality. BITZER is represented all over the world with 65 sites in 34 countries, including its sales companies and production sites. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2018, 3,500 employees generated a turnover of €740 million; expenditure for research and development totalled €37 million.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if “Photo: BITZER” – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.

BITZER Kühlmaschinenbau GmbH

Peter-Schaufler-Platz 1

71065 Sindelfingen

Telefon: +49 7031 932-0

Telefax: +49 7031 932-147

http://www.bitzer.de

Head of Public Relations

Telefon: +49 (7031) 932-4327

Fax: +49 (7031) 932543-70

E-Mail: patrick.koops@bitzer.de

![]()