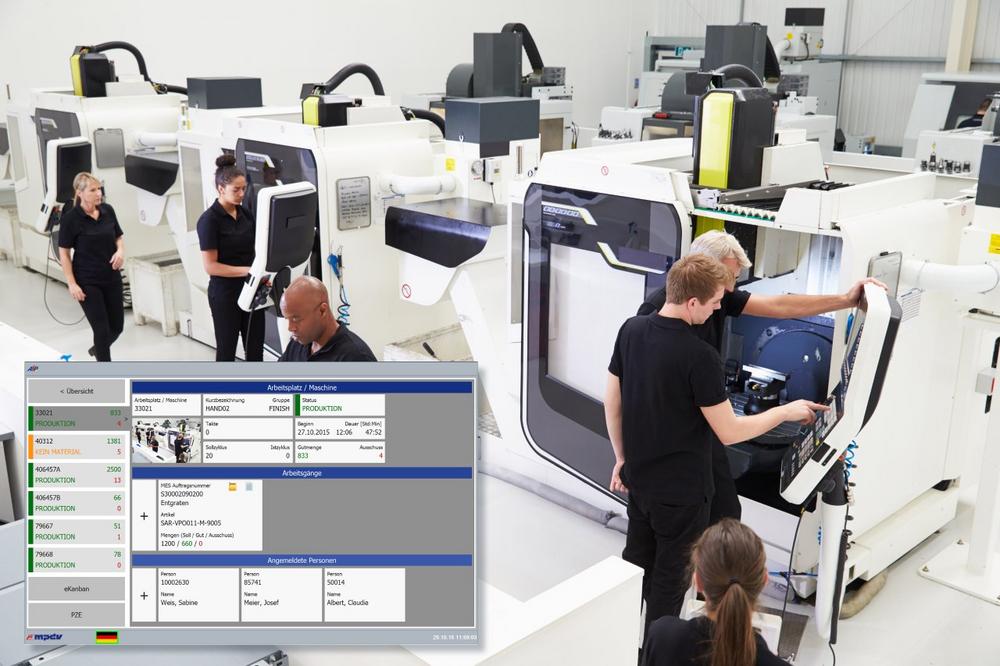

For example, HYDRA can be used to collect order-related information. The aim is to support the production process with digital information and to monitor actual data such as order progress in real time. At the same time, HYDRA BDE with its diverse evaluations and KPIs provides the basis for the entire production control system. HYDRA also supports an improved cost accounting and post-calculation process in the ERP based on actual data. Furthermore, controlling teams benefit from the increased transparency and the fact that KPIs are calculated in a reproducible manner.

Addition to the ERP system

HYDRA BDE adds to the functions of an ERP system that manages all customer orders. A modern BDE system such as HYDRA BDE supports departments close to production to collect order and article-related data according to their own specifications and to plan and organize production processes. HYDRA BDE collects data, evaluates the data and then creates statistics with the supplied information. This allows problems in the production process to be identified and eliminated earlier.

HYDRA BDE supports the production control using simple functions for sequence planning and the resulting reports for connected areas. HYDRA BDE allows supervisors and shift managers to keep track of current orders and work processes and to view and evaluate the progress of past shifts. Users can call different evaluations at all times. As is customary with modern software systems, HYDRA BDE also has flexible administration and editing functions to create or import master data and to correct collected data if necessary.

Overview of functions and benefits of shop floor data collection with HYDRA BDE

- Total transparency of all workflows in production

- Transfer of production orders from the ERP

- Paperless, precise recording of times and quantities

- Improved on-time deliveries

- Shorter throughput times due to the reduction of idle times

- Improved data quality that also benefits the ERP system

- Order monitoring in real time

- Order controlling, evaluations and target and actual comparisons

Please find more information about HYDRA Shop Floor Data (BDE) at: http://mpdv.info/prbde

MPDV, headquartered in Mosbach/Germany, is the market leader for IT solutions in the manufacturing sector. With more than 40 years of project experience in the manufacturing environment, MPDV has extensive expertise and supports companies of all sizes on their way to the Smart Factory. Products such as MPDV’s Manufacturing Execution System (MES) HYDRA or the Manufacturing Integration Platform (MIP) enable manufacturing companies to streamline their production processes and stay one step ahead of the competition. The systems can be used to collect and evaluate production-related data along the entire value chain in real time. If the production process is delayed, employees detect it immediately and can initiate targeted measures. More than 900,000 people in over 1,400 manufacturing companies worldwide use MPDV’s innovative software solutions every day. This includes well-known companies from all sectors. The MPDV group employs around 500 people at 13 locations in China, Germany, Luxembourg, Malaysia, Singapore, Switzerland and the USA. Further information: www.mpdv.com.

MPDV Mikrolab GmbH

Römerring 1

74821 Mosbach

Telefon: +49 (6261) 9209-0

Telefax: +49 (6261) 18139

http://www.mpdv.com

Marketing Manager

Telefon: +49 (6202) 9335-0

E-Mail: n.neubig@mpdv.com

![]()