The developers have done an excellent job of updating the SilverLine. The aim was to increase the productivity and efficiency of the milling cutter and improve process security. And that’s exactly what they’ve done. Many materials can be cut more efficiently with the new generation of SilverLine milling cutters. Due to their universal application capabilities, manufacturing is highly flexible and does not require a large tool portfolio, even when a wide range of services is being offered – for many milling operations the SilverLine is perfectly adequate and will be the tool of choice.

Higher cutting speed, longer service lives

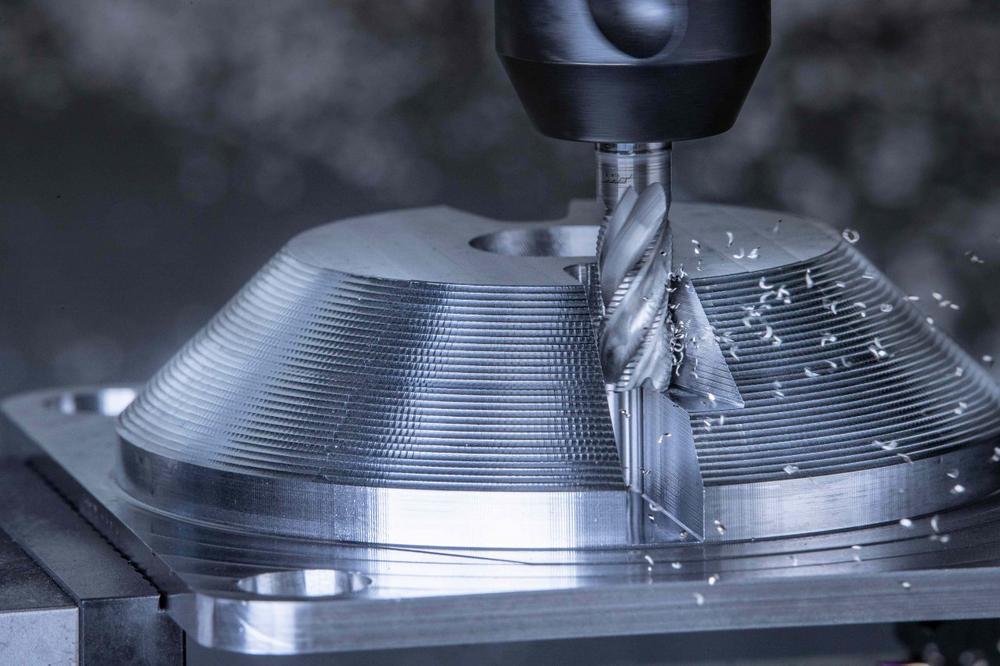

If you liked the WNT SilverLine milling cutters before, you’ll love them now. The results from numerous tests in the Technical Center at CERATIZIT, as well as those from several months of field trials at customer sites, revealed that the new SilverLine achieved a longer service life, despite the higher cutting speeds. The tangible difference: 20 to 40 percent higher cutting values, depending on the material, whether stainless steel or steel, flame-cut, uncoated or scaled. At the same time the service life increased by 30 to 40 percent. In addition, the new SilverLine tools are quieter and reduce the burden on the machine.

Noticeable differences

How are such results possible? After all, the SilverLine VHM milling cutters hardly differ in appearance from those of the new generation. But even though the differences are small they have a significant impact. For example, the milling cutters have a revised cutting edge geometry which ensures an optimised chip flow. Heat generation on the tool is therefore reduced and the tool becomes less susceptible to wear. Furthermore, the modified core geometry protects against an annoying tendency to vibrate even at high contact angles, which reduces chipping on the cutting edge.

Highly efficient protection against wear

In terms of stability the new SilverLine impresses in every detail. A reinforced core diameter increases tensile strength by an astonishing 50% compared to the previous generation. Furthermore, an efficient protective layer protects the SilverLine from wear: the Dragonskin. The latest multilayer coating is characterized by high temperature resistance and enables exceptional service lives to be achieved even with dry machining. Even though these changes can barely be seen with the naked eye, users will certainly notice them.

Extended SilverLine range

Part of the upgrade includes even more versions of the new SilverLine milling cutters. These latest versions will help cover as many application ranges as possible. They feature a larger choice of diameters, several HA shank versions as well as milling cutters with thro‘ coolant. The milling cutters are also available with roughing and rough grinding geometries and there’s even a heavy duty version for full slot milling. Users can therefore draw on unlimited resources and benefit from the latest SilverLine generation in every respect.

The new generation of SilverLine will be available ex-stock when the new CERATIZIT Up2Date catalogue is released in mid-January. A product video and further information will also be found from the above date at cuttingtools.ceratizit.com.

For more than 95 years, CERATIZIT has been a pioneer in the field of ambitious hard material solutions for machining and protection against wear. The private company, with registered offices in Mamer, Luxembourg, develops and produces highly specialised cutting tools, indexable inserts, rods made from hard materials and wearing parts. We are the global market leader in various application segments for wearing parts and are successfully developing new carbide, cermet and ceramic grades, for example in woodworking and stone working.

With more than 9,000 employees at 34 production facilities worldwide and a sales network with over 70 branches, the Group is a global player in the carbide sector. Our international network also includes subsidiaries KOMET, WNT, Becker Diamantwerkzeuge and Stadler Metalle, as well as the CB-CERATIZIT joint venture. As a technology leader, we continuously invest in research and development and hold over 1,000 patents. Our innovative carbide solutions are used in the mechanical engineering and tool making sectors, in the automotive industry, the aviation and aerospace industry, and in the medical industry.

We are represented on the market by our seven flagship brands, Hard Material Solutions by CERATIZIT, Toolmaker Solutions by CERATIZIT, Tool Solutions by CERATIZIT, Cutting Solutions by CERATIZIT, KOMET, WNT and KLENK.

CERATIZIT Deutschland GmbH

Zeppelinstraße 12

87437 Kempten

Telefon: +49 (831) 57010-0

Telefax: +49 (831) 57010-3559

http://cuttingtools.ceratizit.com

PR Manager Cutting Tools

Telefon: +49 (831) 57010-3405

Fax: +49 (831) 57010-3678

E-Mail: norbert.stattler@ceratizit.com

![]()