Guide ring material H-Glide

With the glass and PTFE-filled polymer H-Glide for guide rings, spherical plain bearings or bearing shell inserts, Hunger DFE has a particularly efficient, exceptionally pressure- and wear-resistant material in its product range. With minimal dynamic coefficients of friction and excellent dry-running properties, this material achieves high load-bearing capacities, thereby rendering it predestined for extreme loads in applications in the fields of heavy hydraulics, the offshore and marine sector or mobile hydraulics in mining.

H-Glide is manufactured by injection moulding, is highly dimensionally stable with negligible water absorption and low thermal expansion coefficients. Hunger DFE offers guide mechanisms manufactured from H-Glide of the types FI, FA and FAI, as well as RFI and RFA in a large dimensional range.

As a result, it is possible to specifically adapt the geometry and material to the respective operating conditions of the hydraulic cylinder as a supplement or in combination with the standard material POM compound, which has already proven itself millions of times over.

The result is the best possible performance with regard to functionality and friction, as well as a clear improvement in operational reliability due to the protection it offers against metallic contact.

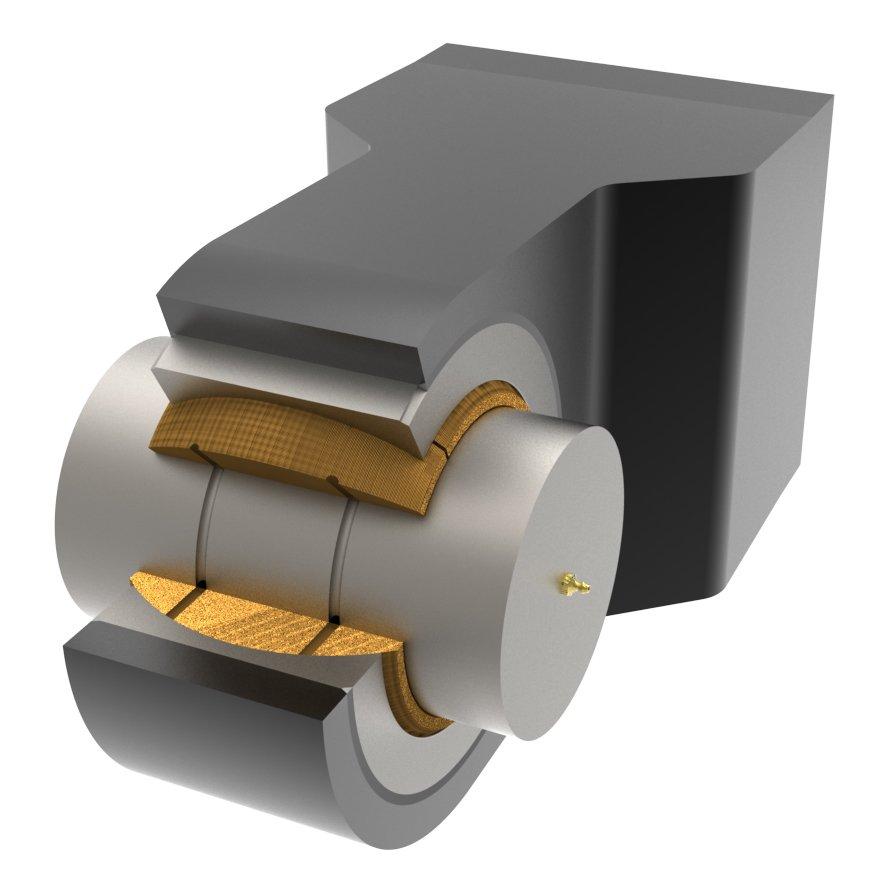

Guide and bearing material H-Tex

(synthetic fibre / phenolic resin / PTFE)

The new fabric composite material H-Tex complements the product range for highly stressed technical components such as bearings, spherical bearings and guide mechanisms. Hunger DFE uses this composite to manufacture complex individual solutions for the oil and gas, heavy and mining industries, as well as highly stressed mobile hydraulics.

Owing to its composition, this phenolic resin-synthetic fibre composite material with integrated PTFE offers excellent and low-friction sliding properties. The extremely high dynamic and static compressive strength with extremely low water absorption, which is far below the measuring limit, makes it particularly suitable for use in maritime applications or in aqueous media.

Due to the material combination with PTFE, almost maintenance-free operating conditions can be achieved and the tribological requirements of materials, especially for bearings or sliding systems, fulfilled.

More information: www.hunger-dichtungen.de

Hunger DFE GmbH, Dichtungs- und Führungselemente

Alfred-Nobel-Str. 26

97080 Würzburg

Telefon: +49 (931) 90097-0

Telefax: +49 (931) 90097-30

http://www.hunger-dichtungen.de

![]()