For several years, Herbold has been operating a washing test centre on an industrial scale in which customers, potential buyers, planners and researchers can test and simulate recycling processes way beyond laboratory level.

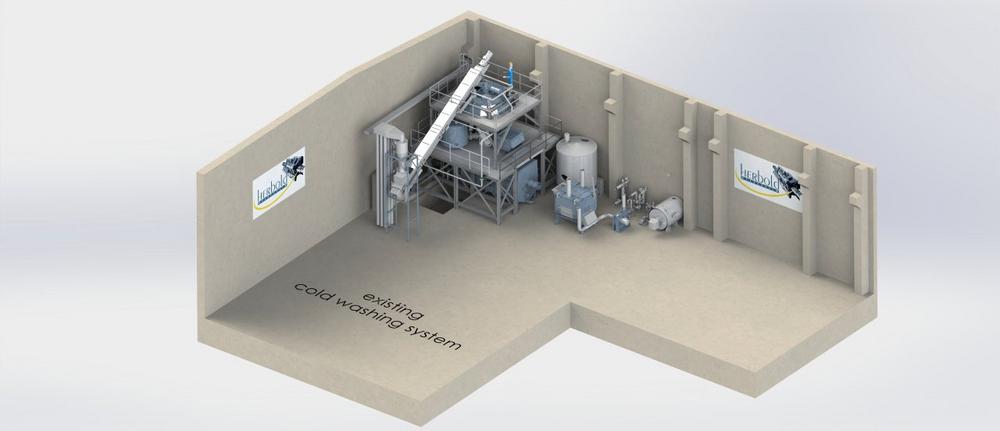

This plant is going to be expanded by a suitable hot washing step. “The new hot washing system replaces the previous pilot plant with which we have been developing the hot washing technology for polyolefin to market maturity in recent years. The new system is far more than a simple hot washing reactor and represents the latest state of technology as it is also implemented in our large-scale plants”, according to Achim Ebel, division manager for washing plants.

The plant allows customers to test the treatment of rigid plastics and films with an output of up to 1,000 Kg/h also in the hot washing system. The plant has been designed for continuous operation and operates in line with the existing hydrocyclone washing plant.

It can be verified whether and how an improvement of the final product is achievable. Especially common in the PET recycling, the hot washing system was traditionally used to remove adhesives with which labels were glued on bottles. The hot washing system is on its way to a demanded process step in the recycling of polyolefin and other plastics; anywhere where complicated residual material, heavy contamination, persistent odours are to be treated or just simply highest quality is demanded. With the hot washing system, a considerable reduction of organic contamination is achieved.

Herbold Meckesheim has delivered a number of plants for hot washing of PET, polyolefin and other plastic materials in recent years and worked for a wide know-how. This is what the pilot plant is now to offer to other projects.

Herbold Meckesheim GmbH is a leading recycling specialist for the plastics industry. The plants contribute worldwide to the reduction and recycling of plastic waste. Herbold’s plants are worldwide in operation. They treat the "clean" waste of the plastic processing industry as well as the used, mixed ad contaminated plastics. The machines are also used in the pulverisation of plastic granules and waste as well as in the other numerous applications in the waste treatment, raw material recovery and material preparation of different industrial processes. Today, Herbold is being managed in the 4th generation by Karlheinz and Werner Herbold and develops and tests the plants in its own test centre. The more than 170 employees in Meckesheim and the employees of the international agencies accompany the machine that was manufactured according to the customer’s application from the planning stage through commissioning to the end of the machine’s operational use. www.herbold.com

Herbold Meckesheim GmbH

Industriestrasse 33

74909 Meckesheim

Telefon: +49 (6226) 932-0

Telefax: +49 (6226) 932-495

http://www.Herbold.com

Marketing

Telefon: +49 (6226) 932-140

E-Mail: daniela.thurner@herbold.com

![]()