The XTO is the first joint project of NOVEXX Solutions and EIDOS – a NOVEXX Solutions company – since their merge in 2017. Customers around the world benefit from the combined expertise and know-how of these two companies. EIDOS already has many years of experience in developing and producing Thermal Transfer Overprinting (TTO) systems. For NOVEXX Solutions the new XTO product is an extension in the product portfolio and a journey into a new product era. Instead of printing on labels, NOVEXX Solutions can now also offer to print directly on packaging film with thermal transfer technology.

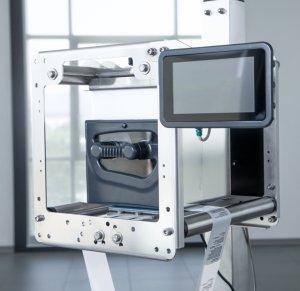

The XTO promises Thermal Transfer Overprinting in a new dimension. It has been developed based on extensive market research and with a strong operator-centric approach. The innovative TTO printer combines excellent print quality and an outstanding uptime with several features that make the machine particularly flexible and easy to operate.

Outstanding ease of operation

The XTO was developed with the operator in mind for maximum user-friendliness. For example the ribbon change is easy and fast. In addition, the printhead can be changed without using any tools. Furthermore, the operator menu for settings, print job selection and printer performance visualization is very intuitive. Another operator friendly benefit is the quick and easy accessibility of components for maintenance and service.

Ribbon change within seconds: the QUICKRIBBON X-LOADER

With the QUICKRIBBON X-LOADER the XTO offers a revolutionary plug & play mechanism for automated ribbon feed and super quick ribbon change. The ultralight loader is affordable, extremely easy to handle and results in increased uptime.

SMART X-MOTOR for optimal print performance

A motor drives the printhead for optimal and controlled printing, resulting in improved performance and uptime. Since no compressed air is required, integration is less complex and operating costs are significantly lower.

The QUICKTRONIC X-CHANGER

The XTO is built on a separation of mechanical and electronical parts. The whole electronic unit can be detached easily even while the XTO is still installed in the packaging line, resulting in improved unit uptime and reduced idle times. All electronic components are easily accessible for fast servicing and maintenance.

The QUICKCHANGE X-PLATE

The XTO has an innovative print plate offering a flexible exchange using VelcroTM material. In case the print plate is damaged or used up, the first layer of the plate can easily be exchanged using the innovative hook and loop system. This results in a reduction of downtime in maintenance as there is no need to uninstall the whole print plate.

Superior print performance and increased uptime

The print area of 53 x 100 mm is about 30 % larger than the market standard and allows more flexibility. The increased "safe operating area" guarantees increased accuracy and excellent print quality even at high printing speed. Additionally, the XTO’s intelligent ribbon save function and maximum ribbon length of 1,200 m lead to an increased uptime.

Revolutionary modular concept

The XTO consists of a print unit, a separate power supply and a separate HMI touchpanel, making it easy to integrate into any existing packaging line. This modularity also leads to increased flexibility in offer and price as every component is optional.

Connectivity and IoT

Various interfaces and features ensure that the XTO is future proof in terms of connectivity and IoT. The printhead includes a crypto chip to store important information such as running kilometers, running hours and print head dotline status. A web server application guarantees maximum flexibility in controlling the XTO. It can be integrated into the display of the packaging machine, run on a separate touch screen or be displayed on an external screen via the browser. This allows a greater operational flexibility as well as remote diagnostics, setup, and maintenance.

"With the XTO, we have achieved a true milestone in the history of TTO technology", says Paolo Bori, Managing Director at EIDOS – a NOVEXX Solutions company. "It combines usability, flexibility and first-class print performance in a unique way and has the best price-performance ration on the market."

About EIDOS – a NOVEXX Solutions Company

Eidos is one of the leading companies in the design and manufacturing of printers for labeling, marking and automatic coding of industrial products. For over 40 years the company benefits from a proprietary technology for the digital thermal transfer printing that prints variable data in real time. Since 2017 EIDOS is a subsidiary of NOVEXX Solutions GmbH.

For further information about Eidos please visit http://www.eidos.eu

NOVEXX Solutions stands for outstanding products and individual complete solutions when it comes to industrial labeling and identification along the supply chain. NOVEXX Solutions combines 50 years of top-class, international expertise with the straightforward flexibility of a powerful mid-size enterprise. The product and service portfolio of NOVEXX Solutions includes hardware and software solutions, high-quality consumables, and professional on-site service. NOVEXX Solutions operates in eleven locations across three continents. For more information, please visit www.novexx.com.

Novexx Solutions GmbH

Ohmstraße 3

85386 Eching

Telefon: +49 (8165) 925-0

Telefax: +49 (8165) 3143

http://www.novexx.com

Marketing Communications Manager

Telefon: +49 (8165) 925-141

Fax: +49 (8165) 925-327

E-Mail: caroline.fiedler@novexx.com

![]()