For the first time, Ensinger will be presenting insulbar RE-LI, which conserves valuable resources in two ways. The insulating profile combines the outstanding environmental footprint of unmixed recycled polyamide with the greater insulating effect of foamed material. Compared to conventional polyamide bars, consumption of fossil fuels and CO2 emissions drop by around 90 %, and water consumption by almost 75 %, in its production phase. In addition, the lambda value is significantly improved thanks to the foamed design of the material.

insulbar insulating profiles for sustainability and efficiency

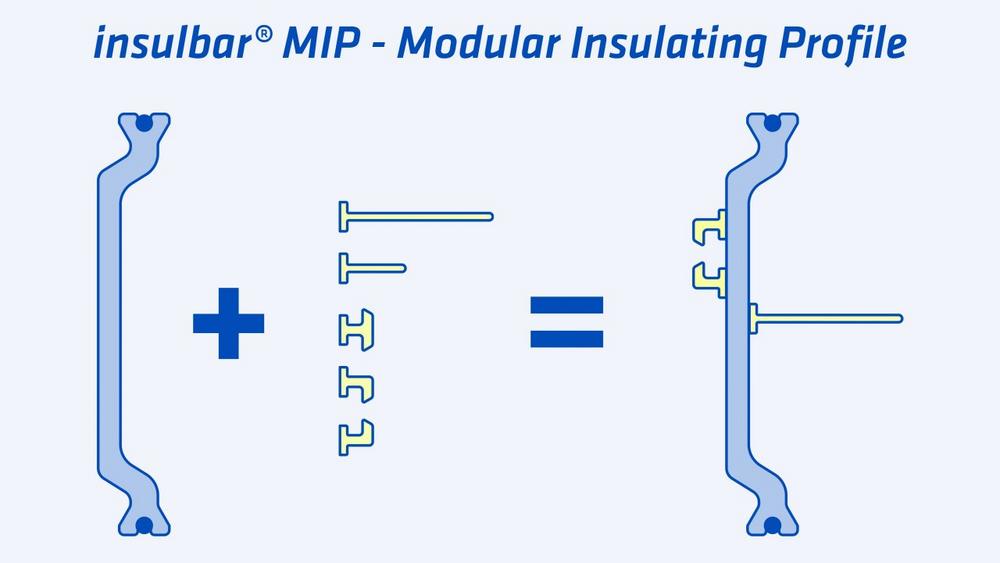

A further innovative concept in the form of insulbar MIP (Modular Insulating Profile) will be showed and discussed. This is a ‘construction kit’ for insulating bars for which a patent has been filed. It allows basic profiles and functional zones to be combined without the need to develop new tools each time. The intention is to use this modular concept to produce a wide variety of profile geometries even more quickly and easily in the future.

Ensinger’s showroom is all about sustainability and conserving resources. All insulbar product solutions contribute to green construction and to the attainment of climate goals. It is not only the core benefit of insulbar, the thermal break in metal frames of windows, doors and façades, but also the materials used, e.g. unmixed recycled polyamide in the case of insulbar RE and RE-LI, which pay into this ‘account’.

About insulbar®

Ensinger GmbH is one of the world’s leading developers and producers of thermal insulating profiles for window, door and facade construction. The profiles marketed under the brand name insulbar create a thermal barrier between the inner and outer shells of metal frames. Insulation solutions using insulbar profiles achieve the best values in terms of energy saving and reduced heating and air conditioning costs, while complying with the most stringent quality standards in every respect. They have been in successful application the world for more than forty years. For more information, go to insulbar.com

The Ensinger Group is engaged in the development, manufacture and sale of compounds, semi-finished materials, composites, technical parts and profiles made of engineering and high-performance plastics. To process the thermoplastic polymers, Ensinger uses a wide range of production techniques, such as extrusion, machining, injection moulding, casting, sintering and pressing. With a total of 2,600 employees at 35 locations, the family-owned enterprise is represented worldwide in all major industrial regions with manufacturing facilities or sales offices. ensingerplastics.com

Ensinger GmbH

Rudolf-Diesel-Straße 8

71154 Nufringen

Telefon: +49 (7032) 819-0

Telefax: +49 (7032) 819-100

http://www.ensinger-online.com

Telefon: +49 (7032) 819-674

E-Mail: k.skrodzki@de.ensinger-online.com

oha communication

Telefon: +49 (711) 508865821

E-Mail: oliver.hahr@oha-communication.com

![]()