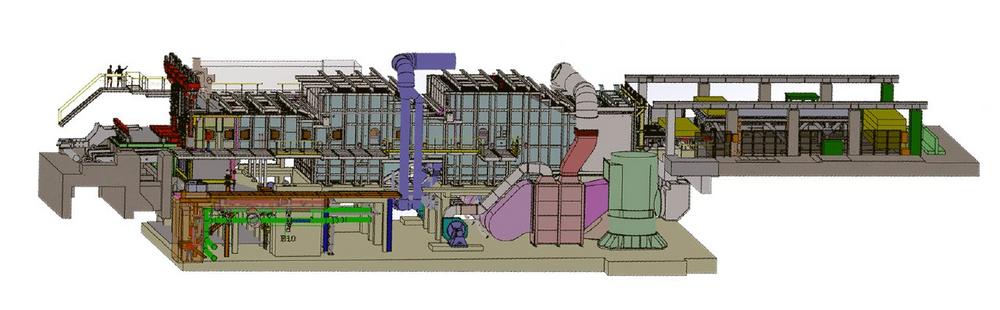

Dillinger France are currently in the process of refurbishing one of their heating furnaces in the rolling mill, pusher furnace no. 2, in the framework of the corporate plan to continuously develop and sustainably secure business activities. The furnace’s recommissioning is scheduled for July 2021. With this refurbishment project, Dillinger France will be enabled to increase their slab steel heating capacity for the rolling of heavy plates, whilst at the same time optimising their energy consumption and CO2 emissions by installing new "high-performance" burners, a heat recovery system for the waste heat inherent in the flue gas, the limitation of thermal losses, and the utilisation of new IT-based furnace operation management models.

With their strategy, the Dillinger Group and its subsidiary Dillinger France are pursuing the targets of the Paris climate agreement and intend to produce top-grade products in a sustainable steel industry environment. Just as their parent company Dillinger, Dillinger France have also been certified for energy management according to ISO 50 001 since 2013, have been striving for the protection of our environment, and have already realised a reduction of their energy consumption by about 6% as well as of their CO2 emissions by approximately 5% during the past seven years. Accordingly, the company has ensured that 60% of the investment volume are spent on the improvement of the furnace’s energy efficiency.

The state subsidies of 1.8 Million Euro provide support for Dillinger France in partially financing their investment volume connected with the decarbonisation, with the objective of increasing the furnace performance by 11 % and of saving 12 GWh of natural gas annually. This corresponds to a reduction of CO2 emissions by 2,300 tons per annum or 2.7 % of the overall emissions produced at the site respectively.

This new investment project of Dillinger France is an inherent part of the Dillinger Group’s "Green Steel" offensive, which furthermore included the introduction of Germany’s very first steel production based on hydrogen in their blast furnaces in August of 2020, following an investment programme of 14 million Euro.

DILLINGER France, a subsidiary of DILLINGER since 1992, one of the world’s largest manufacturers of heavy plates and quality steel, have been producing steel at a site of more than 50 ha in the French region of Dunkirk since 1962. With a staff of more than 500, the enterprise is capable of manufacturing approximately 750,000 tons of heavy plates per annum.

The Dillinger Group (headcount 7,300) generate an annual turnover of several billion Euro. Dillinger’s high-tech sheets are used all over the world for the implementation of exceptional and technically exacting projects, particularly in the construction of offshore wind parks, in steel and mechanical engineering, in the offshore sector in general, for the production of tube plates (line pipe), and in boiler engineering.

Please refer to: www.dillinger-france.com or www.dillinger.de for further information.

AG der Dillinger Hüttenwerke

Werkstraße 1

66763 Dillingen/Saar

Telefon: +49 (6831) 47-0

Telefax: +49 (6831) 47-2212

http://www.dillinger.de/

Telefon: +33 (3) 282939-83

E-Mail: Caroline.doucet@fr.dillinger.biz

Presse- & Öffentlichkeitsarbeit

Telefon: +49 (6831) 47-3011

Fax: +49 (6831) 47-3331

E-Mail: ute.engel@stahl-holding-saar.de

![]()