- Components and systems from Schaeffler electrify the powertrain and enable sustainable mobility

- New releases: Schaeffler 800-volt power electronics and thermal management system increase the range of electric vehicles

- Highly efficient 3-in-1 electric axle combines electric motor, transmission, and power electronics in one system

The automotive and industrial supplier Schaeffler is presenting innovative components and systems at the IAA Mobility 2021 under the motto "On Track to Sustainable Mobility": In addition to efficient bearing and damper solutions for hybrid transmissions, the company is presenting new releases in the form of an 800-volt power electronics system and a highly integrated thermal management system. "Whether individual components or complete systems, Schaeffler is the technology partner of choice for its customers worldwide," says Matthias Zink, CEO Automotive Technologies, Schaeffler AG. "Our decades of expertise in internal combustion engine drives also provides the foundation for shaping the change in e-mobility that will move the world. Numerous serial nominations in the field of electric drives prove that Schaeffler is on the right path.” The volume of orders received in the E-Mobility Division in the first half of 2021 is valued at 2.1 billion euros, which means that the target planned for the whole of 2021 has already been achieved. "Schaeffler’s high level of production and technological expertise across all components of electric drive systems plays a pivotal role in achieving products that are both technically advanced and economical," says Dr. Jochen Schröder, Head of the E-Mobility Division. "An annual order intake of 2-3 billion euros is planned in the E-Mobility Division with effect from 2022."

High-voltage power electronics complement the product range

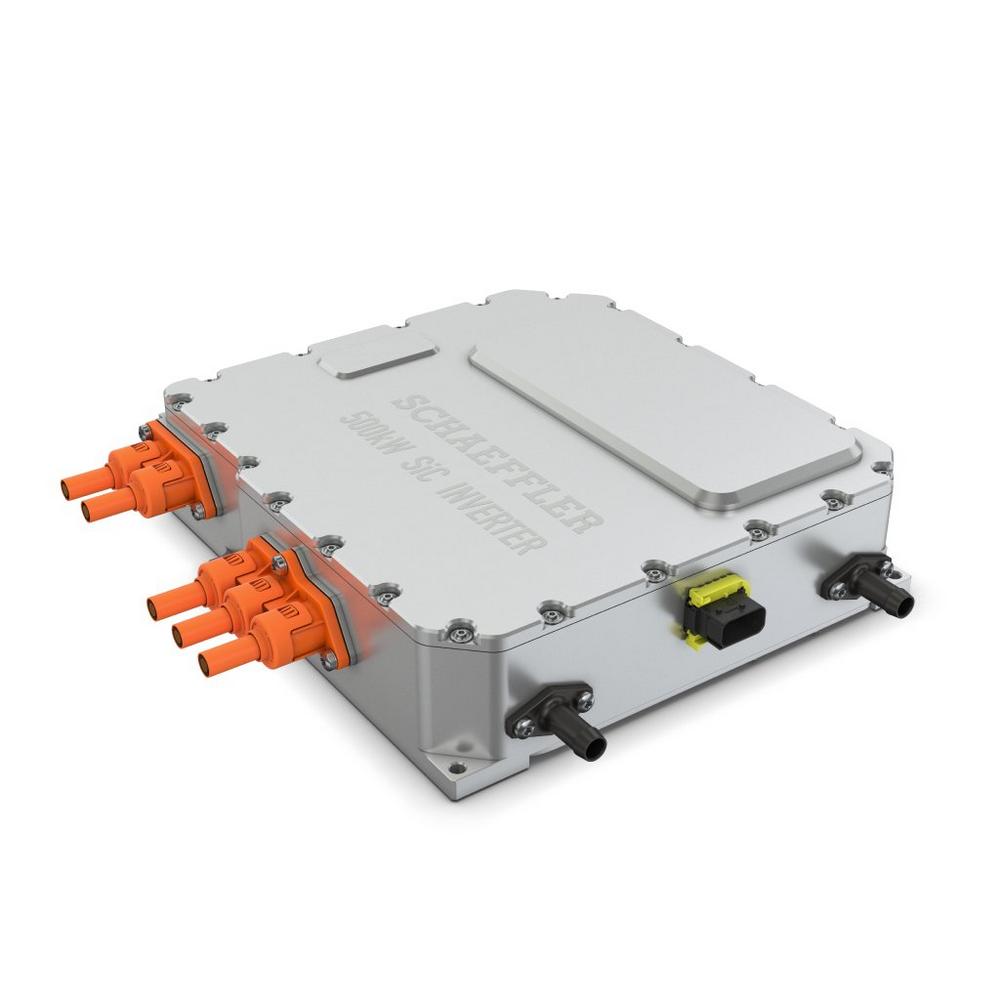

As a new release, Schaeffler is presenting an in-house 800-volt power electronics system for electric axle applications in high-performance vehicles. The scalable solution enables continuous outputs of up to 330 kW and short-term peak outputs of up to 500 kW. The achievable power density of up to 70 kW per liter denotes small housing dimensions and consequently advantages in integration. Power electronics make a decisive contribution, alongside the motor, to powertrain efficiency. Schaeffler has opted to use the latest silicon carbide wide bandgap technology in the 800-volt on-board power supply, which will significantly reduce power losses compared with conventional silicon IGBT technology and enable efficiencies of over 99 percent in defined load ranges. As a result, the overall range of electric vehicles will be noticeably increased. Furthermore, the charging speeds achievable with the 800-volt voltage class are considerably higher than those achieved with the 400-volt voltage class that has been widely used to date. An in-house motor control solution is also used, which enables various modulation processes and variable switching frequencies.

Highly integrated 3-in-1 electric axle

At the IAA, Schaeffler will use its 3-in-1 electric axle, which combines the electric motor, transmission, and power electronics in one system, to demonstrate how performance electronics blend into the overall system. Signal processing and control of the drive is performed by proprietary Schaeffler software. Featuring a transmission with excellent torque density, the performance electric axle from Schaeffler makes a convincing case and is characterized, above all, by its compact dimensions, high performance density, high system efficiency, and excellent acoustic behavior. Thanks to a modular structure, the system can meet different usage requirements and can be used for various vehicle platforms.

Thermal management in a single system for the first time

Thermal management is crucial for the range of electric vehicles. In order to achieve a high level of efficiency, the Schaeffler thermal management system continuously regulates the temperature – particularly of the battery but also of the electric motor, and the power electronics – which is adapted to the ambient and operating conditions. The system also controls the temperature in the interior of the vehicle and simultaneously ensures the best possible vehicle range. Two electric water pumps, the central electronic unit for the pumps and valves, and a refrigeration circuit interface are all integrated in the central control unit for coolants and refrigerants. Compared with conventional, non-integrated systems, this reduces the required installation space by up to 60 percent and, with its hydraulically optimized design, lays the foundation for a high degree of overall system efficiency.

Come and visit Schaeffler at IAA Mobility in Hall B3, Stand A80. The press conference will take place on September 6, 2021, at 1:45 pm and can be followed online at http://schaeffler.gomexlive.com/.

Schaeffler Group – We pioneer motion

As a leading global automotive and industrial supplier, the Schaeffler Group has been driving groundbreaking inventions and developments in the fields of motion and mobility for over 70 years. With innovative technologies, products, and services in the fields of CO₂-efficient drives, electric mobility, Industry 4.0, digitalization, and renewable energies, the company is a reliable partner for making motion and mobility more efficient, intelligent, and sustainable. The technology company produces precision components and systems for powertrain and chassis applications as well as rolling and plain bearing solutions for a multitude of industrial applications. The Schaeffler Group generated sales of approximately EUR 12.6 billion in 2020. With approximately 83,900 employees, the Schaeffler Group is one of the world’s largest family-owned companies. According to the German Patent and Trademark Office (DPMA), Schaeffler was ranked as the second most innovative company in Germany in 2020, submitting more than 1,900 patent applications.

Schaeffler AG

Industriestraße 1-3

91074 Herzogenaurach

Telefon: +49 (9132) 82-0

Telefax: +49 (9132) 82-3584

http://www.schaeffler-group.com

Leiter Finanzkommunikation und Öffentlichkeitsarbeit

Telefon: +49 (9132) 825000

E-Mail: presse@schaeffler.com

E-Mail: daniel.pokorny@schaeffler.com

![]()