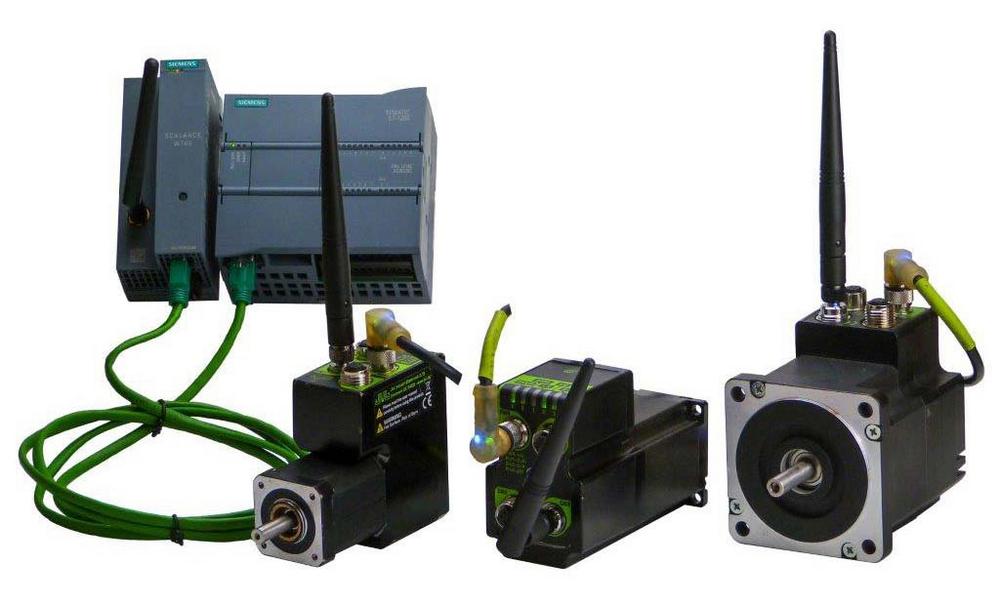

JVL’s ServoStep integrated stepper motors combine a microstepping motor and drive with motion controls and a variety of interfacing and comms’ modules in a single compact unit. The single package integrated motor solution makes wiring straightforward and significantly reduces installation costs, and furthermore provides much better electrical noise protection compared to cabinet housed drives with long noise-prone, motor power and control cable runs. The same ‘builtin technology is applied to JVL’s wide range of integrated servo motors – also available from Mclennan.

ServoStep’s feature a Hall-sensor and an encoder in a proprietary control technology that produces higher torque and precision compared to open loop stepper motors. Options are available with rare-earth rotor magnets that produce up to 40% more torque in same housing size. Motor power through the range spans from 50 to 400 W with speeds up to 3000 rpm and a step resolution of 0.01 revs. An absolute multiturn encoder option boosts positioning resolution up to 409,600 counts per rev. Automatic current-control reduces heating and the quiet motor performance suits noise sensitive applications. The ServoStep MIS series is already available with wired Industrial Ethernet, which is compatible with all major Ethernet protocols – meeting the requirements for IIoT and Industry 4.0 with further options including STO SIL3 for machine safety. A built-in e-PLC™ with eight digital I/O points, or analogue inputs, adds additional application functionality.

Configuration, programming, and communication diagnostics is made straightforward with JVL’s MacTalk® PC application software which includes a graphical programming environment and a wide selection of motion control commands and machine I/O interaction functions.

JVL’s new Wireless Industrial Ethernet option can equally accommodate use with an antenna equipped PLC or a wireless access point for long range communications. MacTalk takes care of set-up with a range of commands including SSID, encryption and credentials as well as signal strength. Two selectable operation modes are available: Station Client, which establishes wireless point to point control of individual antenna equipped integrated motors, and Access Point that allows a number of wirelessly-controlled motors to each be hard-wired to other ServoStep motors through a secondary Ethernet connection. Station Client mode is used where multi-axis synchronisation is not an issue, and Access Point mode should include a managed Ethernet switch of industrial grade in the wireless network topology for best axis and machine I/O synchronisation.

With its own UK-based design and build service Mclennan is a distribution partner for JVL and other selected motion control component and systems manufacturers, providing stepper and servo motor-based automation solutions from single components to complete systems including software, training and comprehensive after saes support. For further information please contact Mclennan at sales@mclennan.co.uk or visit www.mclennan.co.uk.

Mclennan works closely with a small number of global motion control manufacturers and with its own inhouse design and manufacturing capability the Hampshire based motion specialist offers complete integrated mechatronics assemblies with customised mechanics, gearheads and other power train components. Motor technologies include brushed and brushless servo motors, stepper motors, small AC motors and complementary gear unit drive technologies together with motion controls for competitively priced multi-axis motion and machine control for use throughout industrial and OEM automated machine applications – contact Mclennnan at sales@mclennan.co.uk or www.mclennan.co.uk.

Mclennan Servo Supplies Ltd

Unit 1, The Royston Centre, Lynchford Road,

GU12 5PQ Surrey

Telefon: +44 (1252) 531444

Telefax: +44 (0) 8707 700699

http://www.mclennan.co.uk/contact-us

Telefon: +44 (1252) 531444

E-Mail: jon.bentley@mclennan.co.uk

MEPAX

Telefon: +44 (7748) 815-825

E-Mail: e.palmer@mepax.com

![]()