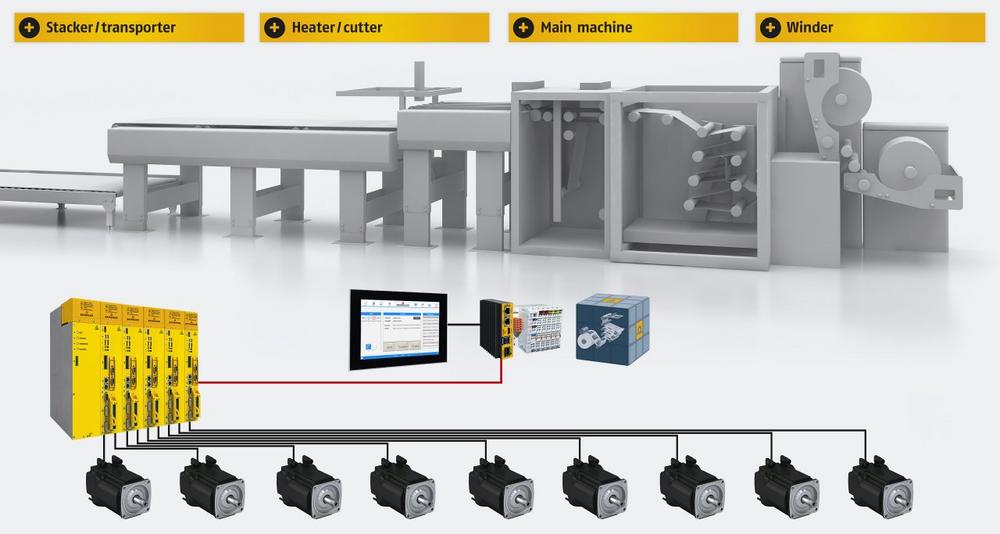

Baumüller’s software templates save developers a lot of time: The templates contain a large number of the required functions as well as motion modules and templates for functions such as alarm handling and prepared visualizations. This means that machine programmers no longer have to worry about the basics during development and can instead put the time saved to full use in process programming. With the Web & Foil software template specifically tailored to web processing machines, Baumüller is expanding its machine templates to include another industry solution.

Web processing machines usually have a virtual master axis to which the other drives of the individual process steps are synchronized. The template can be used for machines and systems for paper and foil production, e.g. in foil bag, corrugated board, folded carton and printing machines.

The advantage: Complete template instead of individual libraries

Many automation providers merely deliver the individual libraries for the respective software project. By contrast, the Web & Foil template not only contains the necessary libraries but also, e.g. includes general templates for implementation of the visualization or fault management.

In addition to the basic functions, the Web & Foil software template also includes machine functions.

Basic functions

The developer does not have to set up the basic functions again from scratch, but instead they are selected and parameterized directly. Routine tasks such as the instancing of motion modules or linking variables with the modules are no longer necessary.

- Virtual master – maser shaft, on which the other drives can synchronize within the machine. The function is mapped via the MC_MasterEngine function module.

- Cams – specified movement of a slave axis depending on the position of the virtual maser. Not only dynamic, jerky profiles, but also jerk-limited movement profiles can be mapped.

- Recipe management – management of the product-related settings at the machine. With this function the settings can be stored, loaded, edited and exported.

- User level management – Each user can be assigned different rights for operation and access to functions and settings of the machine.

- Monitoring – monitoring of the individual machine modules, for example, monitoring of the status of the inputs/outputs, the fieldbus or specific values on the basis of a graphic evaluation (e.g. servo motor temperature).

- Alarm handling – machine faults are collected and displayed. These can be acknowledged via the visualization after they have been eliminated.

- Manual mode – The individual motors can also be run in manual mode, for example, for material or format change.

Machine functions

The templates contain frequently used machine functions for paper and foil processing. These only have to be adjusted to the respective application.

- Impeller – Is the connection between the welding unit and foil placement. Modules for this are provided in the template, which enable operation via cams.

- Register control – The modules for print mark detection are included. Based on this, machine-specific register control can be implemented.

- Cam group – control, for example, of time-controlled or position-controlled cams including dead time compensation.

- Heating bar – The temperature control for the heating bar is included.

- Cutting – Depending on how the cutting unit is executed mechanically, here it is possible to implement this function using different technologies.

- Feed – Material is conveyed into the machine.

- Stacking– Foil placement can also be implemented via existing cam functions. Positioning via positioning modules would also be possible.

With the Web & Foil software template for web processing machines, developers save a lot of time, especially in the start-up phase of a project, and can therefore better concentrate on the important machine functions. For the machine manufacturer, this means a faster time-tomarket and significantly reduced development costs.

Based in Nuremberg, Baumüller is a leading manufacturer of electric automation and drive systems. At production sites in Germany, the Czech Republic, Slovenia and China as well as in over 40 branches worldwide, around 2,000 employees develop and produce intelligent system solutions for machine manufacturing and e-mobility.

In addition, the range of services offered by the Baumüller Group includes engineering, assembly and industrial relocation as well as services, thus covering all aspects of life cycle management.

Baumüller Gruppe

Ostendstraße 80-90

90482 Nürnberg

Telefon: +49 (911) 5432-0

Telefax: +49 (911) 5432-130

http://www.baumueller.com

Marketing Communications Manager

Telefon: +49 (911) 5432-319

E-Mail: stefanie.lauterbach@baumueller.com

Marketing Manager

E-Mail: L.Kemnitzer@baumueller.de

![]()