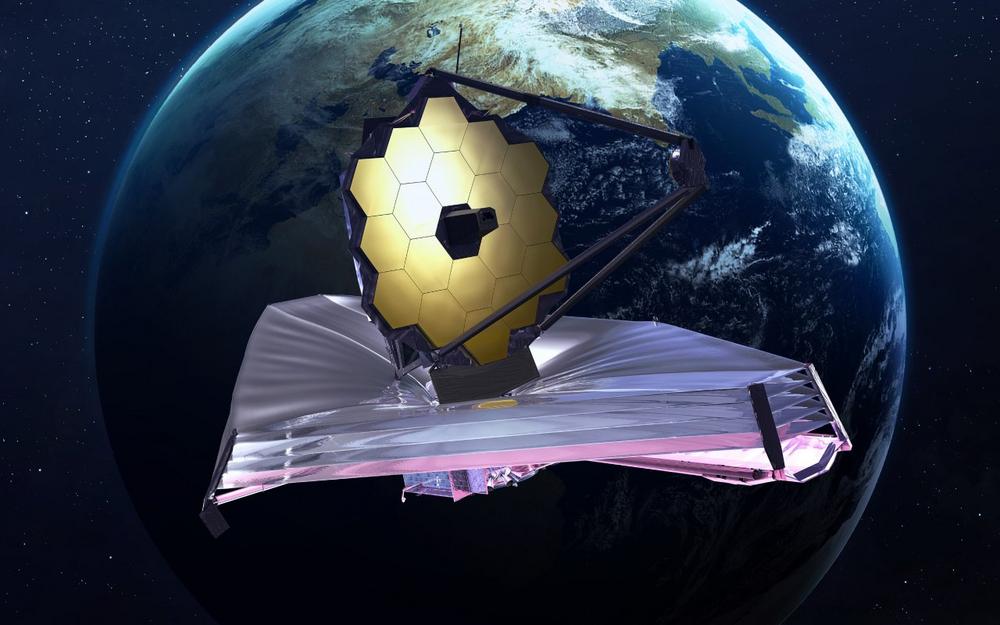

This primary mirror is a triumph of engineering. It folds up small enough to fit into a launch vehicle, and then deploys to full size once in space. Once completely opened, the positioning and surface shape of the mirror segments is accurate enough – to within tens of nanometers – to enable the assembly to deliver the optical performance of a single 6.5meter mirror.

The primary mirror segments themselves are the result of contributions from several different organizations. These include companies that created the beryllium mirror blanks and then formed them into hexagons before sending them to Coherent Tinsley for surface shaping and polishing, and then other companies that performed tests on the mirror segments before eventually sending them back to Coherent for even more polishing and final gold coating.

There are just a few organizations in the entire world that possess the expertise, skill, equipment, and dedication to fabricate freeform optics this large to the astonishing level of precision required for the James Webb Space Telescope to operate properly. Coherent Tinsley is immensely proud to have contributed a key component for this project. And, now, our work continues as we perform polishing and hexing of 231 of the 492 freeform, aspheric, 1.52meter diameter mirror segments for the ground-based Thirty Meter Telescope.

Coherent

Dieselstr. 5b

64807 Dieburg

Telefon: +49 (6071) 968-0

Telefax: +49 (6071) 968-499

https://www.coherent.com/de

PR Europa

Telefon: +49 (6071) 968-0

Fax: +49 (40) 73363-4138

E-Mail: petra.wallenta@coherent.com

![]()