We cannot lay the foundations for or accelerate the digitization of politics, business or our private lives without powerful and reliable data centres. All of our data is stored and processed in data centres. They consume a tremendous amount of energy. According to a recent study by the German IT and telecommunications association Bitkom, data centre experts believe that efficiently cooling data centres and making effective use of the waste heat are the sustainability measures with the greatest potential.

We are used to using the internet anywhere and at any time, communicating digitally as part of a remote office or homeschooling, and saving data to maximise its availability. The data needed for this to happen is processed in data centres, the number of which is rising sharply. There are around 50,000 in Germany alone, according to Bitkom. The capacities of German data centres increased by 84 per cent between 2010 and 2020 alone, and are expected to rise by around one third by 2025.

Data centres and their energy requirements

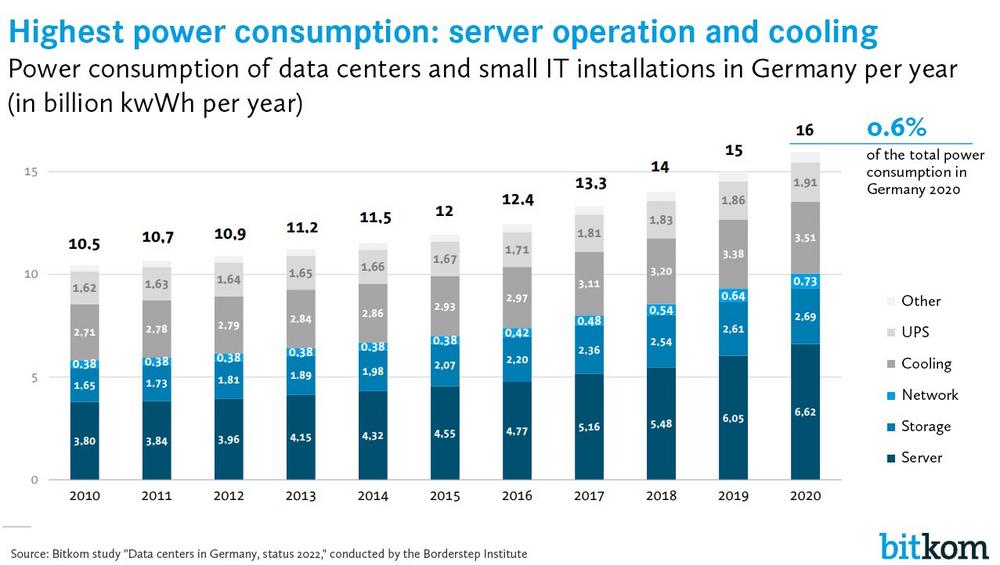

Data centres depend on reliable, efficient cooling to function and make full use of their capacity. ‘Energy efficiency is a major issue for data centres because their energy consumption is extremely high. Data centres account for between 1 and 1.5 per cent of the world’s energy consumption. Cooling has a major effect on energy efficiency,’ explains Mathias Layher, Director Sales AC, Marine and Process at BITZER. According to Bitkom, around 22 per cent of the total electricity consumption of data centres is attributable to cooling. This is the largest share after server operation.

Data centres do not take breaks; they have to operate reliably 24 hours a day, seven days a week, and they generate waste heat in the process. Servers cannot perform optimally without consistent moderate temperatures which require constant cooling. This makes the reliability of the refrigeration system an essential factor: the more constant the cooling, the more stable and efficient the processes. Cooling systems are responsible for up to 20 per cent of the overall costs associated with a data centre as they ensure reliable, efficient data centre operation. Modern systems allow for increasingly efficient cooling and take advantage of the waste heat which cooling systems transport away from the server rooms.

BITZER and data centres

‘BITZER provides highly efficient screw and scroll compressors as well as heat exchangers to cool data centres efficiently and make effective use of waste heat,’ says Layher. ‘The products must be extremely reliable. This is always important – all the more so for data centres.’ If, for example, you compare the standard model of the ORBIT scroll compressor from BITZER against the ORBIT+ scroll model from the refrigeration and air conditioning specialist, you will see that the cooling capacity of ORBIT+ compressors with line start permanent magnet motors (LSPM) in air and water cooled systems is between three and five per cent higher than the ORBIT standard model. Moreover, the ORBIT+ scroll compressor boasts a higher seasonal energy efficiency ratio (SEER) that is five to eight per cent higher than the standard model.

An example of how BITZER products can be used in data centres: as one of the first systems with the adiabatic system, the Italian company HiRef S.p.A., which specialises in manufacturing air conditioning systems for areas containing technical hardware and technology, relies on BITZER products. Adiabatic cooling is a method of controlling the temperature of rooms with the evaporative cooling power of air and water. The task was to design a cooling system that is both as reliable and sustainable as possible for a data centre in the German city of Offenbach, in cooperation with Cooltec Systems Kälte Klima GmbH. The solution: for the first time, 96 screw compressors with external frequency inverters were installed in the 48 cooling systems instead of scroll compressors. With screw compressors, certain temperature levels can be maintained precisely and constantly. If the preset maximum temperature set point is exceeded, the evaporative cooling system lowers the condensing temperature and therefore the energy intake. Speed-controlled by frequency inverters, the screw compressors provide full mechanical backup for the refrigerating capacity. Capacity control makes the screw compressors extremely energy efficient. For more information about cooling with the adiabatic system from BITZER and HiRef, visit: HiRef is using screw compressors from BITZER to cool a data centre adiabatically

With screw and scroll compressors forming part of a redundant cooling system, BITZER uses its own products and both branches of compressor technology in the data centre at its headquarters in Sindelfingen. The waste heat from the servers is blown into two heat channels and a heat exchanger uses it to provide heating where it is needed. BITZER is planning to set up an energy management system that will collect all the relevant data and whose efficiency can be measured on the basis of preset key performance indicators. The data centre of the refrigeration and air conditioning specialist was recently certified with the TÜV seal of quality in terms of availability and protective capacity.

About World Refrigeration Day

The motto of the fourth World Refrigeration Day on 26 June is ‘Cooling Matters’. The subject of data centres is an excellent example of the importance of cooling. The refrigeration and air conditioning industry uses World Refrigeration Day to raise awareness of its importance. It is no coincidence that World Refrigeration Day falls on 26 June each year: the physicist William Thomson, 1st Baron Kelvin, was born on 26 June 1824. In 1848, at the age of 24, he developed the thermodynamic temperature scale. Even today, the absolute temperature is still measured in units of Kelvin in his honour. For more about World Refrigeration Day, please see www.worldrefrigerationday.org.

As an independent specialist for refrigeration and air conditioning technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always striving for the highest possible energy efficiency and quality. BITZER is represented all over the world with 72 sites in 38 countries, including its sales companies and production facilities. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2021, over 3,900 employees generated a turnover of €928 million; expenditure for research and development totalled €47 million.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.Als unabhängiger Spezialist für Kälte- und Klimatechnik ist BITZER weltweit im Einsatz: Mit Produkten und Dienstleistungen für Kältetechnik, Klimatisierung, Prozesskühlung und Transport sorgt BITZER für optimale Temperaturbedingungen in Warenhandel, Industrieprozessen und Raumklimatisierung – immer vor dem Hintergrund größtmöglicher Energieeffizienz und Qualität. Mit Vertriebsgesellschaften und Produktionsstätten ist die BITZER Firmengruppe weltweit an 72 Standorten in 38 Ländern vertreten. Inklusive Handels- und Dienstleistungspartnern erstreckt sich der Fertigungs-, Entwicklungs- und Vertriebsverbund von BITZER über fast alle Länder der Welt. Im Jahr 2021 erwirtschafteten über 3.900 Mitarbeiter einen Umsatz von 928 Millionen Euro, der Aufwand für Forschung und Entwicklung lag bei 47 Millionen Euro.

BITZER Kühlmaschinenbau GmbH

Peter-Schaufler-Platz 1

71065 Sindelfingen

Telefon: +49 7031 932-0

Telefax: +49 7031 932-147

http://www.bitzer.de

Head of Public Relations

Telefon: +49 (7031) 932-4327

Fax: +49 (7031) 932543-70

E-Mail: stefanie.holst@bitzer.de

![]()