Analyses need data

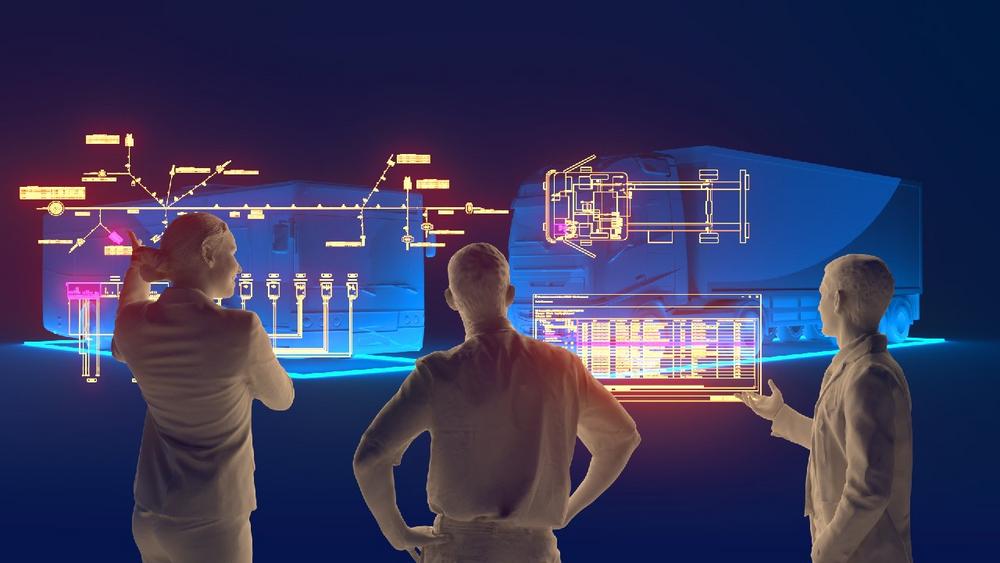

The prerequisite for this is EB’s central data model of the on-board power supply, which grows continuously from the initial component and signal definition to the vehicle configuration and the manufacturing information and always keeps all the relevant data together throughout. It is only thanks to this database – in contrast to purely graphical on-board power supply documentation – that it is possible to analyze and calculate various scenarios, for example for weight and placement optimization. For example, the selection of disconnection points for the wiring can be optimized by simulation, or the effects of relocating an ECU in the vehicle on the on-board power supply can be checked.

Plans magically appear

The whole thing is rule-based, each company being able to define its own rules in addition to some basic rules that EB already provides. Once they have been defined in EB, the Design Center supports the on-board power supply experts with additional capabilities: Since it is aware of all the components, signals, connections created and the 3D data converted into a 2D design, including their interrelationships in the EDS, it automatically selects the most suitable wire for routing. And for the finally selected EDS scenario , just a few clicks enable the Design Center to generate the follow-up documents. Circuit diagrams and the 2D harness drawing are created as if by magic – with tested components, optimized placement and correct, cost-optimized wiring.

Waiting times and misunderstandings are a thing of the past

Those who work with conventional, drawing-oriented tools usually first have to define the e-components and connectors, then draw the circuit diagrams, and finally define the wiring. Given the large number of plans, this takes an enormous amount of time – also because of the inevitable queries and changes from the various experts involved in the EDS development process. With EB, on the other hand, waiting times, coordination and misunderstandings are a thing of the past, because everyone works on the same model and details it with their specialized knowledge. In the process, everyone sees directly what the others have developed. In this way, the EDS Design Center "knows" all on-board power supply aspects and interrelationships and thus creates the possibility for analyses and automatically generated plans.

"Hidden Heart"

"As the heart of every vehicle, the on-board power supply is a ‚hidden champion‘. It has been gaining in complexity and importance for years, thanks to increasing requirements for functional safety, vehicle equipment, and the development towards autonomous driving, but it plays virtually no role in the decision to buy a vehicle," says Georg Hiebl, the product manager responsible for Aucotec’s Mobility division, and emphasizes: "However, consistent digitization must not stop at EDS planning. This hampers overall vehicle development and quality enormously." IZB visitors can see how EB’s data-centred concept is advancing the digitization of vehicle electrical system development using a variety of examples at the Aucotec stand.

Aucotec at IZB 2022: Hall 2, Stand 304

Aucotec AG has more than 35 years‘ experience in the development of engineering software designed for use throughout the life cycle of machinery, plant equipment and mobile systems. Solutions range from flow diagrams and process-control/electrical technology for large-scale plant systems to modular on-board power supply units designed for the automotive industry. Software supplied by Aucotec is currently in operation throughout the world. In addition to the headquarters in Hanover, the Aucotec Group includes six other locations in Germany as well as subsidiaries in China, India, South Korea, the Netherlands, France, Italy, Austria, Poland, Sweden, Norway and the USA. What is more, a global partner network ensures local support all over the world.

AUCOTEC AG – EN

Hannoversche Straße 105

30916 Isernhagen

Telefon: +49 (511) 6103-0

Telefax: +49 (511) 614074

http://www.aucotec.com

Presse & Öffentlichkeitsarbeit

Telefon: +49 (511) 6103-186

Fax: +49 (511) 614074

E-Mail: jki@aucotec.com

![]()