- DOMO fully committed to market demand for circular solutions in mobility, E&E and consumer goods sectors

- Sustainable TECHNYL® 4EARTH supporting e-mobility and glycol resistant solutions for auto cooling applications, flame retardant and orange-colored polyamides to meet demand for sustainability among innovations on show at K 2022

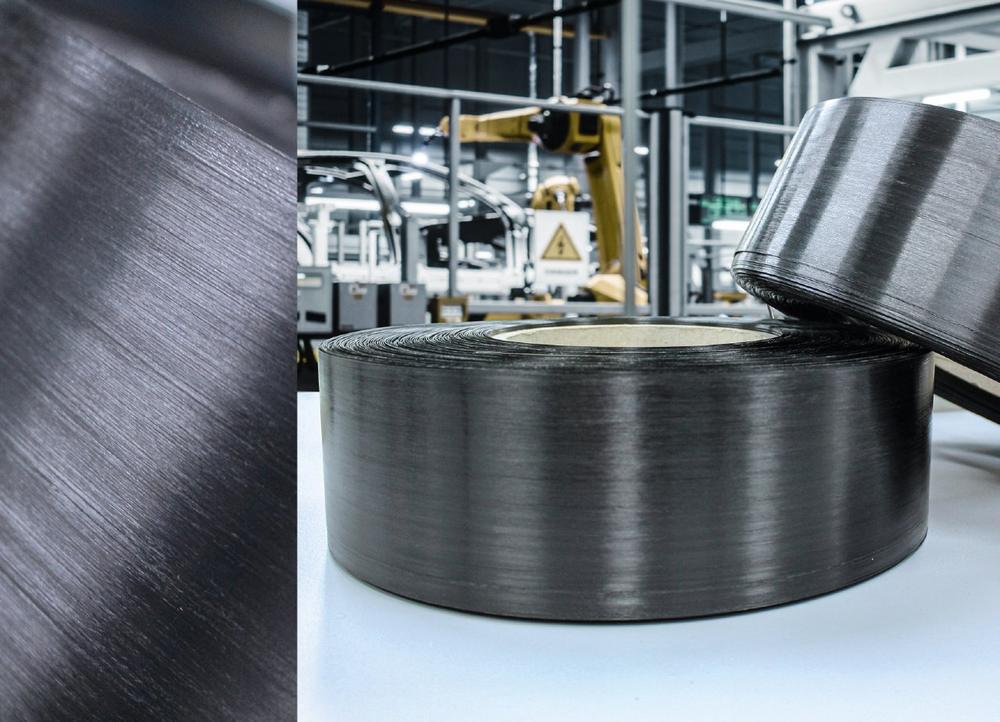

- New brand, TECHNYL® Lite, offers solutions for fiber-reinforced composites (UD tapes)

- Other key solutions, including those used for water management and power tool applications, to be showcased at DOMO’s external pavilion: OA Hall 4 in booth 04.3

DOMO Chemicals, a leader in polyamide-based engineered material solutions and services, is set to present its entire range of high-performing TECHNYL® solutions to a global audience for the first time at the upcoming K 2022 show in Düsseldorf, Germany.

Climate protection and the circular economy are key themes of K 2022, which takes place between October 19-26. The event will serve as a platform to share experiences with stakeholders across the entire value chain, and innovations that will help create a safer and more sustainable plastics and polyamides industry.

As well as exploring DOMO’s latest circular innovations, visitors to K 2022 will also be able to discover more about the company’s highly ambitious sustainability objectives and collaborations through their Xperience external pavilion OA Hall 4 in booth 04.3. In addition, DOMO will also be showcasing its innovative Service Hub simulation and testing capabilities.

Here is a more detailed roundup of what to expect from DOMO at K 2022:

Solutions and partnerships take center stage

Creating and using circular solutions with reduced carbon footprints continues to be a major challenge for the industry.

Recent developments in lightweighting, metal replacement, thermal management and e-mobility reinforce the global need for sustainable and high performing polyamide-based solutions. At K 2022, DOMO will show a range of new solutions designed to meet these growing needs.

The TECHNYL® 4EARTH portfolio continues to expand, and a key highlight at K 2022 will be the launch of two new circular lines in the product family. Designed for cooling applications, the TECHNYL® 4EARTH A1E 218 V30 BK 34NG LP is a sustainable variant of DOMO’s leading coolant resistant grade (TECHNYL® A 218 V30 BK 34NG). For E&E market needs, the TECHNYL® 4EARTH HFFR and flame-retardant polyamides – available in gray and white – are based on recycled feedstock with reduced CO2 emissions compared to virgin alternatives.

Another major focus for DOMO at K 2022 will be geared towards supporting increased processability in the E&E market. TECHNYL® C 102 NC DF, for example, is a new PA6-based, unfilled solution that provides optimal processability and is aligned with market standard requirements, especially for the production of electric plugs, sockets, switches and connectors.

In the domain of e-mobility, new electrically friendly and orange solutions will be presented with improved electrical performance and processability, together with color retention capability beyond aging at 130°C for 1000h. In addition, DOMO will be showcasing its unidirectional UD tapes (composites) with high stiffness and strength for lightweighting solutions under its new brand, TECHNYL® Lite. These tapes will help further enhance plastic applications, specifically for structural parts used in automotive and consumer goods.

Working closely with customers, DOMO recognizes a shift away from pipe, fittings, pumps, valves and other components being made from traditional materials such as brass, steel and other metals. There is an increasing demand for innovation among water management solutions, and this is where TECHNYL® SAFE plays a key role. Visitors at K can expect full insight from DOMO’s experts on how this sustainable product is making strides for higher performing systems that are better protected against corrosion and degradation.

Excellence in sustainability and performance through co-creation

As well as displaying its own innovations and products for visitors at K 2022, the show also represents an opportunity to demonstrate the importance of collaboration and partnerships in solving the world’s challenges. DOMO is working closely with key partners, such as Grundfos, to close the loop with sustainable material production and recycling.

“With Grundfos, we are presenting a pilot to increase circularity whereby we recall their post-industrial feedstock and use them as a base for new products,” comments Maarten Veevaete, Director Application Center at DOMO.

This important partnership is exactly the sort of initiative that is supported by Circularise, a blockchain-based traceability platform that will bring greater transparency to the plastics sector by enabling customers to track exactly where their products have come from.

On Day 3 of K 2022 (October 21), the company will be presenting another collaboration in a joint presentation with CLARIANT, highlighting their work to increase the glycol resistance of flame-retardant polyamides. Together, the companies will present a new set of data explaining how the type of flame retardant and nature of the polymeric matrix impacts the material performance after glycol ageing.

Leading the transition from a linear to circular, resource-efficient economy

As sustainability is the major underlying theme of K 2022, the show provides the ideal platform for DOMO to present to industry stakeholders its highly ambitious sustainability objectives.

In line with its customers’ priorities and global consumer expectations, DOMO has revised its sustainability targets with a focus on decarbonization, renewable energy consumption and customer solutions.

“We aim to advance circularity in polyamides and secure sustainable value creation in our industry,” commented Ludovic Tonnerre, DOMO’s Chief Commercial Officer at DOMO. “Based on TECHNYL®, we focus on solutions that help enable the transition from a linear to a circular, resource-efficient economy.”

Currently, around 10% of DOMO’s product sales are from circular solutions. The company plans to grow this to 20% by the end of the decade, and to 30% by 2035. The key to this will be the development of Nylon 6 and 66 quality feedstocks for use in high-quality engineering compounds. Here, DOMO is exploring technologies and solutions around depolymerization, nylon dissolving, and new feedstock recycling.

Maarten Veevaete added: “As the leader in sustainable polyamide technologies, we are progressing with our ambition in terms of post-industrial and post-consumer feedstock along with depolymerization and dissolving technologies as energy-efficient chemical recycling. If we are to treble the proportion of sales from circular products, we will need to keep accelerating these important programs.”

Regarding operational CO2 emissions, DOMO is making serious strides with hydrogen. On Day 1 at K 2022 (October 19), Chief Corporate Development Officer Wilfried Debus will introduce the company’s joint project with Hynamics to produce polyamides from low carbon hydrogen, known as HyDom. By 2027 the plant at DOMO’s Belle-Étoile site will supply 100% of the energy for the production of hexamethylene diamine, a key component used in the production of plastics.

Xperience TECHNYL®

All of this work around product development and sustainability is embodied by the TECHNYL® brand architecture.

At K 2022, visitors will experience how DOMO is responding to megatrends such as e-mobility, miniaturization, urbanization, lifestyle and circular low carbon industry. Crucially, performance is not sacrificed in the name of environmental responsibility – TECHNYL® represents a family of high-performance engineered materials that are now available to customers worldwide and shipped through their local operation hubs, with expanded production in China set for the latter part of 2023.

Just as crucial to DOMO’s present and future offering is the Service Hub. At K 2022, visitors can engage with DOMO on accelerated development cycles through its unrivalled part testing capabilities. The company’s simulation experts will be available to discuss success cases, application simulations and prototypes, and guide visitors through a virtual lab tour.

“With so much to tell the world at K, we are really excited about this event and have great expectations,” added Ludovic Tonnerre. “Our plans for international growth and continued portfolio expansion, including the addition of more circular products, are in full swing. Now is the time to work together in our journey to build momentum and get the word out there.”

K 2022 takes place in Düsseldorf, Germany, from October 19-26. DOMO invites all guests to visit its external pavilion OA Hall 4 in Booth 04.3 throughout the week. Meanwhile, both Ludovic and Maarten will be available for comment at the press breakfast along with Yves Bonte, CEO of DOMO Chemicals and Wilfried Debus, Chief Corporate Development Officer of DOMO Chemicals.

DOMO Chemicals offers polyamide-based engineered materials solutions and services for a diverse range of markets, including the automotive, consumer goods, industrial goods, electricals and electronics industries. Based on the company’s upstream and downstream integration, DOMO also serves the agriculture, chemicals, pharmaceuticals, fibers and textiles sectors. Our complete portfolio of polymer-based products and services includes chemical intermediates, resins, engineering plastics and performance fibers.

Headquartered in Belgium, the family-owned international group leverages innovative technology, advanced application expertise and a caring mindset to deliver sustainable solutions for our stakeholders. DOMO generated 2021 sales of over EUR 1.9 billion and employs approximately 2200 people across our global production sites and sales offices.

www.domochemicals.com

DOMO Chemicals GmbH

Am Haupttor – Bau 3101

06234 Leuna

Telefon: +49 (3461) 43-2200

Telefax: +49 (3461) 43-2220

http://www.domochemicals.com/

Marketing Communications Manager Polymers & Organic Intermediates

Telefon: +49 (3461) 43-2146

E-Mail: marc.chalupsky@domo.org

![]()