Advanced automobile manufacturers and press line operators not only check the oiling of the strip before the stamping process, but instead or additionally apply a tailor-made oiling to the stamped metal sheets. The target oil layer thickness varies across the blanked sheet area and can, for example, be lower at edges or cut-outs than on the rest of the plate.

A similar requirement was communicated to EMG Automation (Beijing) Ltd. by a world renowned carmaker and press line operator in Chins. Traditionally, oil layer measuring instruments are arranged in uncoiling and blanking units in automobile pressing workshops. The main reason for such an arrangement up to now, was the difficulty to detect oil layer deviations online in the press.

Since 2015, EMG Automation (Beijing) has begun to study the application possibilities of EMG online oil layer measuring solutions across different automobile pressing units. In 2016 the basic understanding of the respective requirements led to a first system order of a pressing shop in China for the oil layer measurement on individual sheets in the automotive pressing process. The equipment has been in normal production use ever since installation. With continuously increasing recognition of this technology across the entire pressing industry, more and more automotive companies are paying high attention to online oil layer measurement.

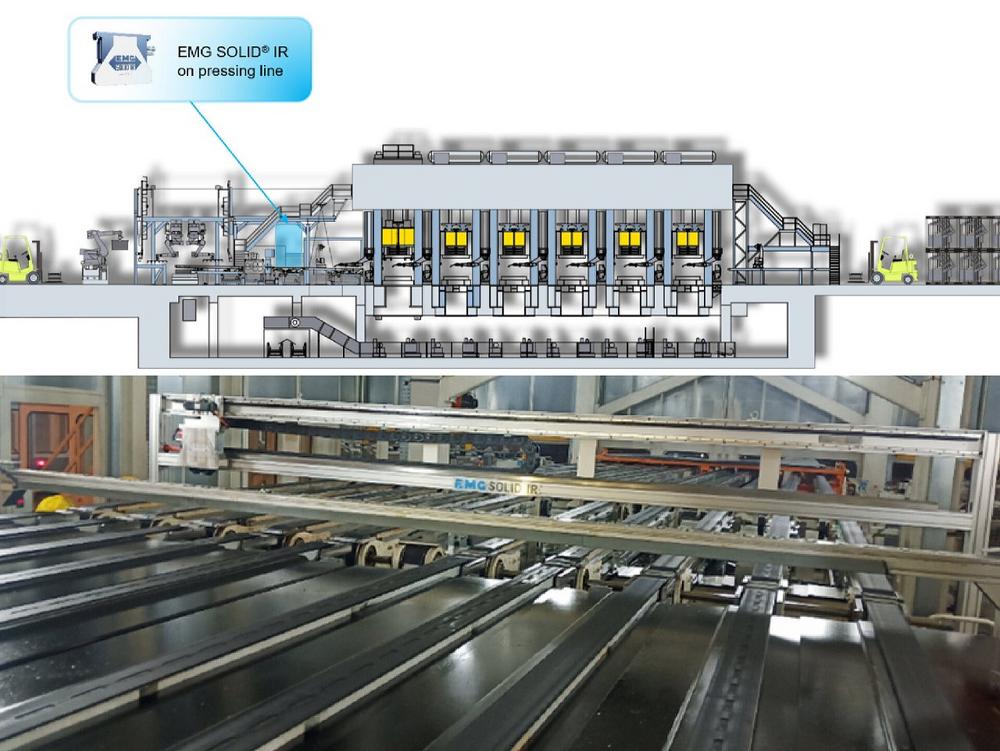

Compared to a measurement on endless strips, this system’s software required extensive adaptations and special solutions. The programming work was mainly carried out by EMG Beijing with expert support from EMG Germany. EMG SOLID® IR, the infrared spectroscopy-based EMG solution, is now successively applied in 2 further pressing units at another renowned car maker in China. It realises online measurement of oil layer thickness along the pressing line to collect real-time oil layer thickness values at any position of the material with visualisation of such results. With the possibility to measure surface oil layer before the material is fed into the pressing die, the system can also be used to measure residual oil on the material surface in real time. Thanks to the visualisation of real-time values, average values, and statistical values according to time and material number, it offers additional support to ensure process and quality tracking.

With the use of the EMG SOLID® IR online oil film measurement in this modern pressing plant, more and more material quality information can be processed intelligently, which takes the user to a new level of intelligent use of production data in the pressing process.

EMG SOLID® systems are available based on both infrared spectroscopy and laser-induced fluorescence technology. The selective use of these two technologies puts EMG in a unique position to offer the user the optimum solution for his requirements.

For more information on EMG SOLID® IR and LIF, please visit our homepage at EMG SOLID® – Oil layer measurement and feel free to contact our international sales organisation or for China directly our colleagues at EMG Beijing at any time.

More info:

EMG SOLID® Brochure: 20220712_Brochure_EMG_SOLID_EN_Rev00.pdf (elexis.group)

Video: EMG SOLID® Oil layer measurement – infrared and laser induced fluorescence

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Product Marketing

Telefon: +49 (2762) 612-282

E-Mail: Claudia.Schreiner@emg-automation.com

![]()