In recent years, there has been a visible trend in polymeric solutions and metal replacement in automotive industry. In internal combustion engine cars, engineered polymers are being widely used and it gets even more when it comes to EVs due to the vital need for range extension and higher efficiency. From an economical point of view, there are more justifying factors for polymeric solutions in EVs. Main supply chains need to be reshaped, and polymer suppliers need to adapt to new metal-to-plastic conversion, and light-weighting requirements. These open up new opportunities for high performance polymers such as ROTEC® HPPA.

ROTEC® HPPA is a high performance polyamide that has been designed to be used as metal replacement. This compound combines metal-like strength and rigidity with very low moisture absorption rate (up to 60% lower rate than PA6). It has also very low thermal expansion (close to that of aluminum and zinc alloys) that makes it well-suited for metal insert molding. Flame retardant (V-0 rating at 3mm thickness) and UV resistant grades have been developed for specific applications.

ROTEC® HPPA can be injection molded using standard machines with no need for special tools/equipment that is necessary for some other high performance polyamides. The main added values of ROTEC® HPPA can be described as follows:

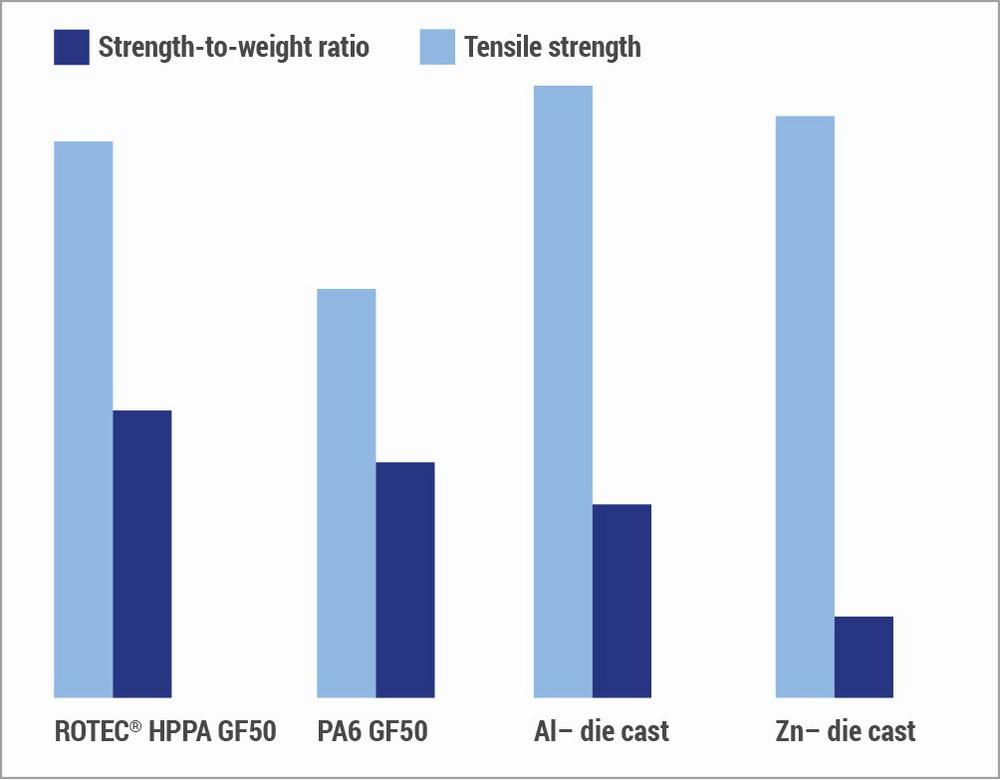

- Lighter and higher efficiency: ROTEC® HPPA has high strength-to-weight ratio whereby complex structural parts as strong as aluminum with 40 % weight reduction can be produced using glass fiber reinforced ROTEC® HPPA

- Design innovation: injection molding of ROTEC® HPPA gives more design flexibility than metal forming techniques so that multiple metal parts can be effectively integrated to a single part

- Cost and time saving: the use of ROTEC® HPPA eliminates extra costs induced by additional metal production steps such as drilling, finishing, and assembly. Also, mold wear and maintenance level is much lower than metals.

- Less total CO2 emission: lower weight, less carbon footprint in raw material production and final fuel consumption

The application of ROTEC® HPPA is not limited to metal replacement but also as substitution to standard PA6 and PA66 compounds where there is risk of failure due to moisture absorption and degradation of properties. In particular, functional parts in vital need for retaining mechanical properties over a long service period. The other application is in thin wall parts where high rigidity/modulus cannot be achieved by standard PA6/ PA66 compounds. The high strength-to-weight ratio of ROTEC® HPPA allows it to be served for downsizing and thinning of PA6/PA66 parts.

In case there is demand for a higher level of weight saving, carbon fiber filled compounds could be possible solutions. High price and carbon footprint are the two main concerns about carbon fiber reinforced compounds in automotive industry. The use of re-processed virgin carbon fiber in ROTEC® PA compounds results in a considerable decrease in carbon footprint, and total costs.

ROMIRA GmbH was founded in 1990 and is an affiliated partner within the ROWA GROUP. As part of this strong combine, ROMIRA sets standards for technical plastics with its profound competence and synergetic know-how.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

E-Mail: m.vaezi@romira.de

![]()