E-cars are becoming more and more popular. According to the German Federal Motor Transport Authority, they accounted for around a fifth of all newly registered passenger cars in Germany last year. Globally, the share of e-cars rose from 14 per cent in 2022 to 18 per cent in 2023, according to the International Energy Agency (IEA). As part of an international network, TÜV Rheinland is currently involved in testing prototypes of photovoltaic modules integrated in vehicles’ roofs, known as "Vehicle Integrated PV" (VIPV). The focus is to check the applicability of current available international measurement standards for testing these innovative devices and to evaluate the amount of energy such devices can produce when installed in vehicles in real application. To date, there are no international standards specific for such solar modules. The aim is to develop new international standards that serve as guidance for industries and testing laboratories for reliable measurements ensuring the correct and fair comparability of those devices. Successful testing could lead to the development of more sustainable and energy-efficient vehicles with reduced dependence on traditional fuel sources.

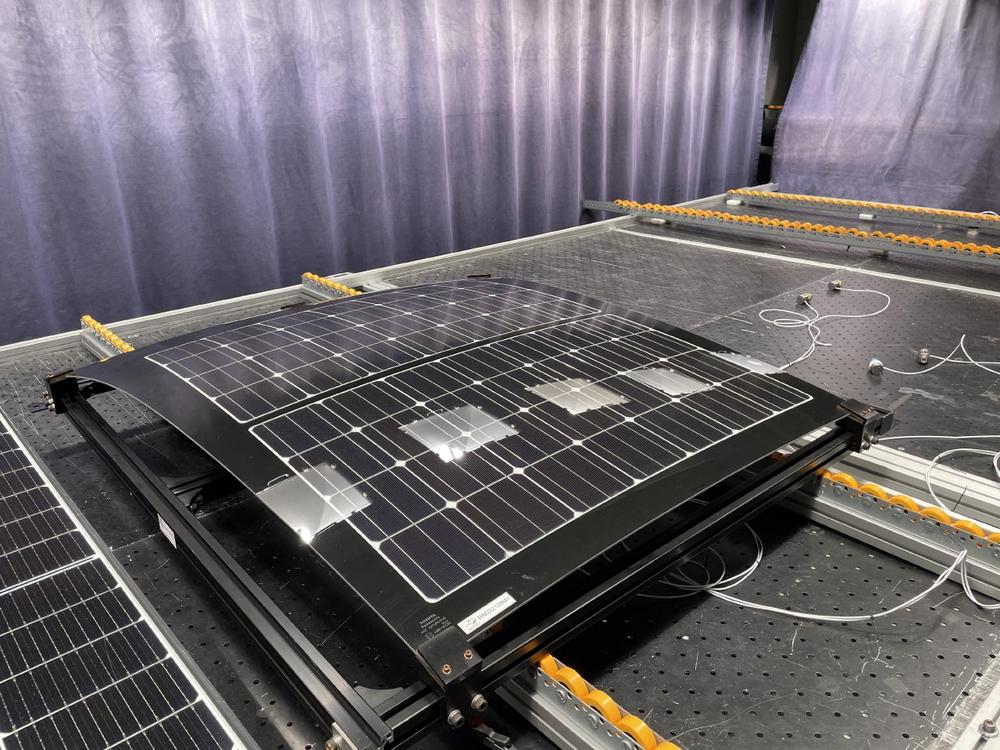

"The integration of photovoltaic modules on vehicle roofs is possible and works. A particular challenge is the rounded and irregular shape of car roofs – especially in terms of assessing the power performances under indoor solar simulators," says Giorgio Bardizza, R&D global manager in the solar sector at TÜV Rheinland. "Solar modules on vehicle roofs cannot have a planar surface and their shape typically depends on the vehicle type and model. Thus, the selection of the test plane is non-trivial and current available regulations lack in its definition. This is one of the aspects affecting measurement comparability and currently under investigation."

The integration of PV panels on electrical vehicle roofs offers an additional way of generating energy increasing the driving range. Due to the high energy requirements of cars, it is not possible to use PV modules alone. However, previously unused areas can be used for additional energy generation, especially in larger vehicles. The potential of this new technology is therefore enormous. "As TÜV Rheinland, we have the expertise and capacity to test and inspect pioneering technologies," says Giorgio Bardizza.

Since 2018 the Technical Committee 82 of the International Electrotechnical Commission (IEC) has identified the need to address standardization of the design and performance of PV in automotive applications. The project team PT600 was established by the University of Miyazaki in Japan and involves numerous testing laboratories around the world, including TÜV Rheinland. The aim of the project is to develop two new technical reports focused on monitoring solar irradiance around the vehicles and modelling its distribution to VIPV. Two laboratories of TÜV Rheinland (one in Cologne, Germany and another in Shanghai, China) dealing with PV devices and systems are involved in this group. Recently they participated in the first international measurement intercomparisons of VIPV modules organized by PT600 group and tested the prototypes already developed by Toyota in cooperation with Panasonic.

The results of such intercomparison will have multiple benefits: on the one hand, TÜV Rheinland test results are passed on to the VIPV car roof developer so that the product can be further developed and improved. But more importantly, they form a basis for discussion by the IEC for the development of new international standards.

A future update of the already existing IEC standards IEC60904-9 (Classification of characteristics of solar simulators), IEC60904-1 (Measurement of photovoltaic current-voltage characteristics) and IEC60891-2 (Method for temperature and irradiance corrections to measured I-V characteristics) is expected taking into account specific aspects and issues of VIPV modules. In addition, the International Organization for Standardisation (ISO) is considering integrating environmental and mechanical tests into the ISO16750 standard.

TÜV Rheinland’s current testing phase and participation to the PT600 group activities will continue until mid-2024, with further results expected in the autumn, which will be used to develop new standard documents (very probably technical reports) for VIPV in 2025.

Safety and quality in almost all areas of business and life: That’s what TÜV Rheinland stands for. The company has been active for more than 150 years and is one of the world’s leading testing service providers. TÜV Rheinland has more than 20,000 employees in over 50 countries and generates annual sales of around 2.3 billion euros. TÜV Rheinland’s highly qualified experts test technical systems and products around the globe, accompany innovations in technology and business, train people in numerous professions and certify management systems according to international standards. In this way, the independent experts ensure trust along global flows of goods and value chains. Since 2006, TÜV Rheinland has been a member of the United Nations Global Compact for more sustainability and against corruption. Website: www.tuv.com

TÜV Rheinland

Am Grauen Stein

51105 Köln

Telefon: +49 (221) 806-2148

http://www.tuv.com

Communication Manager

Telefon: +49 (0) 221 806-3522

E-Mail: contact@press.tuv.com

![]()