Classic application

Beta backscattering methods, which were previously used to determine the layer thickness, will soon reach the limit of their availability. Different isotopes are used for different weight ranges. For example, Promethium, which was previously used for inline coating thickness measurement, will only be available on the world market for a very limited period of time (approx. 1 year).

EMG SOLID® DFT – Measurement with laser-induced fluorescence spectroscopy

In recent years, EMG has extended the already widely established technologies of the EMG SOLID® system family for the determination of oil layers to the application of electrical steel coatings. As a reminder: EMG SOLID® is based on two technologically different measuring methods, which are preferred depending on the application. These are an infrared spectroscopic method, EMG SOLID® IR, and a sensor system based on laser-induced fluorescence, EMG SOLID® LIF. Extensive field tests and laboratory investigations have shown that EMG SOLID® LIF technology is generally the best solution for determining the coating thickness of electrical steel coatings and is equal to or superior to the isotope-based measurement method. Simultaneous temperature measurement of the strip surface is important in this application as the fluorescence behaviour of some varnishes is significantly temperature dependent. This is true for traversing and stationary sensor heads. The EMG SOLID® DFT system compensates for precisely this effect for successful use in the production of electrical steel sheets.

Another significant advantage of this measurement method compared to classic beta backscattering is that the LIF method is a direct measurement with only one measuring spot and not a comparative measurement with two measuring spots (uncoated and coated).

Key to success: laboratory measurements and calibration

Precise laboratory measurements and calibration curves based on them are the ‚conditio sine qua non‘ for determining the coating thickness and not just the area weight. EMG has expanded its own laboratory equipment in such a way that sample measurements can also be carried out for different degrees of throughout-dryness with manageable effort. For calibration, a reference method in accordance with DIN standard is used to determine the dry film thickness in µm. This distinguishes EMG calibration from alternative methods in which only the area weight is determined and the coating thickness is calculated on a user-specific basis using different conversion factors.

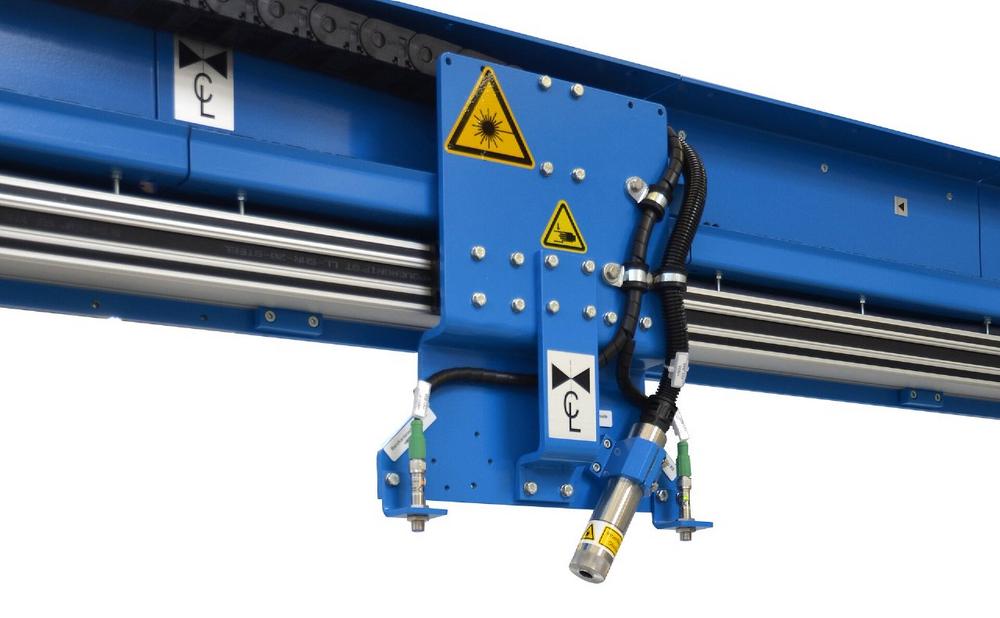

Installation in the line

Due to the small dimensions of the EMG SOLID® LIF measuring head, which is used both to illuminate the strip with UV laser light and to detect the induced fluorescence radiation, the integration into existing or new production lines is generally possible without any problems. In addition, as this is a laser of laser class 1, no special protective measures are required. The measurement is carried out either continuously traversing or, for example, in three tracks, depending on the user’s preferred quality assurance method. The measuring distance to the strip is 40 mm and the measuring spot has a diameter of 8 mm. The head itself is no larger than a torch (180 mm long and 35 mm in diameter).

Conclusion

The results of laboratory tests and a series of initial production applications clearly show that the EMG SOLID® LIF system can be used to provide very good quantitative verification of the insulating varnishes analysed on electrical steel for surface quantities in the g/m² range (layer thickness 0.5 µm…10 µm). As more than 90 % of the insulating varnishes used in the standard production processes of electrical steel have been analysed, EMG SOLID® DFT is developing into a radiation-free and future-proof "game changer" for the reliable determination of dry film thicknesses of insulating varnishes on electrical steel.

Curious?

Would you like to know more about EMG SOLID® DFT and the associated application possibilities? Please feel free to contact our sales department, our international sales organisation or our product manager Timo Gemmer (timo.gemmer@emg-automation.com) directly at any time. We look forward to hearing from you!

Further information can also be found in the EMG SOLID® DFT brochure.

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Product Marketing

Telefon: +49 (2762) 612-282

E-Mail: Claudia.Schreiner@emg-automation.com

![]()