Redefining Material Control System Boundaries

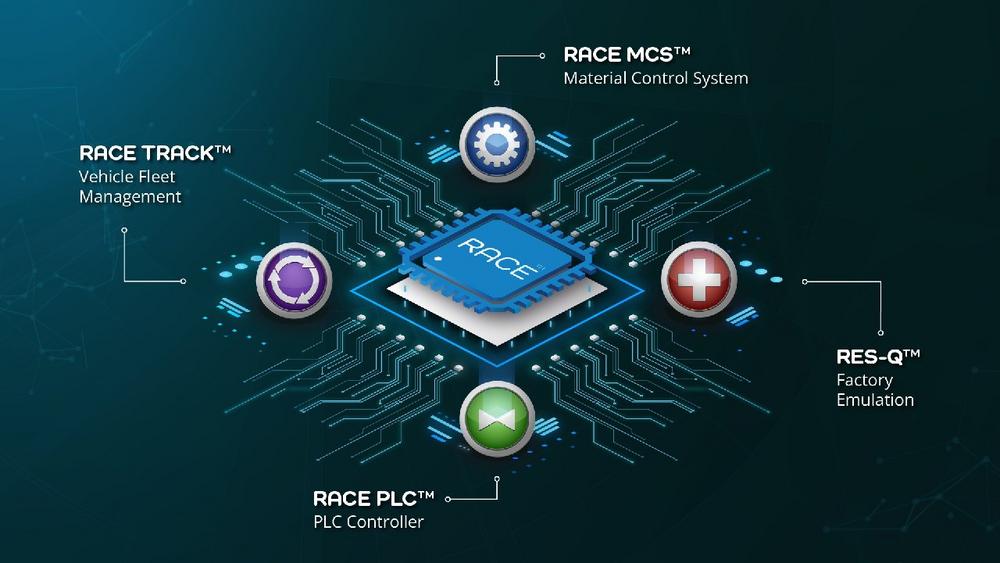

The name RACE MCS™ is derived from the Romaric Automation Control Engine (RACE™) and Material Control System, emphasizing the robust RACE™ engine powering the MCS. Transitioning from ROMA MD™ to RACE MCS™ reflects Romaric’s dedication to continuous growth, innovation, and entry into new markets.

RACE MCS™ addresses the need for MCS across various industries, beyond just semiconductors. Its capabilities have been expanded to support additional types of robotic automation devices.

“This is a significant milestone in our over 20-year journey,” says Rory Gagon, CEO and founder of Romaric. “We are extending the influence of the world’s only third-generation MCS, taking its innovative applications beyond the semiconductor industry and into new, diverse sectors.”

Impact on Existing Valued Customers

Existing ROMA MD™ customers will experience no disruptions and can continue using the system without any actions required. The product roadmap will proceed under the new brand, RACE MCS™.

Future software updates for RACE MCS™ will maintain the versioning sequence from ROMA MD™. Starting November 1, 2024, users will see RACE MCS™ reflected in the system’s graphical user interface.

About Romaric

Romaric, now part of camLine group has been a leader in automated material handling system (AMHS) software, providing material control systems (MCS) for over two decades. Specializing in the semiconductor industry, Romaric offers automation solutions across diverse industries, leveraging expertise in robotic integration to ensure interoperable fleet management and maximize throughput. romariccorp.com

camLine has been recognized as a valued IT solution partner for high-tech manufacturing over the past 35 years. Industry automation systems are based on MES/MOM modules. Numerous implementations can be found in semiconductors, electronics, automotives, solar, batteries, medical devices, and renewable energies across Europe, North America, and APAC. In addition to service domains on quality assurance, process integrity, production logistics, OEE, monitoring and reporting, camLine’s solutions feature the orchestration of shop floor activities among different communication layers. As part of Elisa IndustrIQ, AI and machine learning (AI/ML) techniques are integrated in statistical methods to foster optimal engineering analysis and defect control. camline.com

camLine

Fraunhoferring 9

85238 Petershausen

Telefon: +49 (8137) 935-0

http://www.camline.com

Business Development & Marketing Manager

E-Mail: vy.trinh@camline.com

![]()