The refrigeration, air conditioning and heat pump industry can expect changes in the areas of refrigerants and energy efficiency as a result of the Montreal Protocol, the EU F-Gas Regulation, the Ecodesign Directive and potential PFAS bans. ‘But what we generally view as challenges of the future can also offer major opportunities,’ says Martin Büchsel, Chief Sales and Marketing Officer at BITZER. ‘We are doing what we can to ensure they benefit our customers and partners. Especially when it comes to refrigerants and energy efficiency, we not only offer solutions based on products, but can also provide ideas for concepts. For the past 90 years, we at BITZER have been driven by the vision of shaping the future with our customers. We represent #morethanacompressor and #greencompetence.’

Naturals refrigerants for future-proof systems

With F-Gas Regulation 2024/573 and potential PFAS bans, Europe is heading for a future based on minimal use of HFCs. To ensure investments over the long term, BITZER expressly recommends natural refrigerants when planning new refrigeration, air conditioning and heat pump systems based on BITZER components in the EU. BITZER has offered components for R717 (ammonia) since 1973, for hydrocarbons since 1990 and for R744 (CO2) since 1998. At Chillventa, the company will be presenting innovations from its extensive product portfolio for natural refrigerants. For example, the

ECOLINE 8-cylinder reciprocating compressors for subcritical CO2 applications expand the series

to include higher capacity ranges with the refrigerant R744 (CO2) – especially for industrial refrigeration. The compressors are designed for high standstill pressures of up to 80 bar. BITZER is also the only manufacturer to include reciprocating, screw and scroll compressors for R290 (propane) in its portfolio. The company will be showcasing these along with the ECOLINE PRO, CS PRO and ORBIT PRO series at Chillventa. Components for R717 (ammonia) will round off the BITZER product portfolio for natural refrigerants at Chillventa. Open drive OS.A105 screw compressors come in three displacement volumes – 1400, 1700 and 2000 m3/h at 2900 rpm – and offer high capacities for industrial refrigeration.

Further information about innovations is available in the enclosed product profiles.

Energy-efficient systems are an absolute must

When it comes to financial business success and efforts to increase sustainability, energy efficiency is more important than ever before for both new and existing systems. Efficient systems not only reduce energy and operating costs and increase system availability, but also decrease the indirect emissions associated with energy consumption and thus the carbon footprint. The great potential often lies in the details.

Designed to fulfil market requirements, BITZER compressors offer maximum efficiency and boast a long lifetime. One example is the line-start permanent-magnet (LSPM) motor technology of the ECOLINE+ series, which uses high motor efficiency and low heat input into the refrigerant to reduce energy consumption. Advanced capacity control is essential when it comes to further improving efficiency in full and part load, which is why BITZER offers a range of options which are optimally tailored to its compressors and enable precise capacity adjustment based on actual refrigeration and heating requirements. At Chillventa, the company will offer information about the opportunities provided by the VARIPACK frequency inverter and VARISTEP mechanical capacity control. These technologies can be optimally combined in new systems, but also offer benefits when it comes to retrofitting existing systems for the purpose of optimising energy consumption.

Thanks to a wide range of capacity modulation of the compound system, both the minimum load and varying cooling and heating loads up to the maximum load are optimally covered. Precise capacity control optimises dynamic system behaviour, improves control accuracy (CF) and lowers temperature differentials in heat exchangers, thus reducing fluctuations in pressure, which result in losses, and high cycling rates. Calculations demonstrate that precise control of compressor capacity can increase system efficiency considerably. Raising the evaporation temperature by 3 Kelvin can improve efficiency by up to twelve per cent, whilst reducing the condensing temperature by 1 Kelvin can improve efficiency by another two to three per cent.

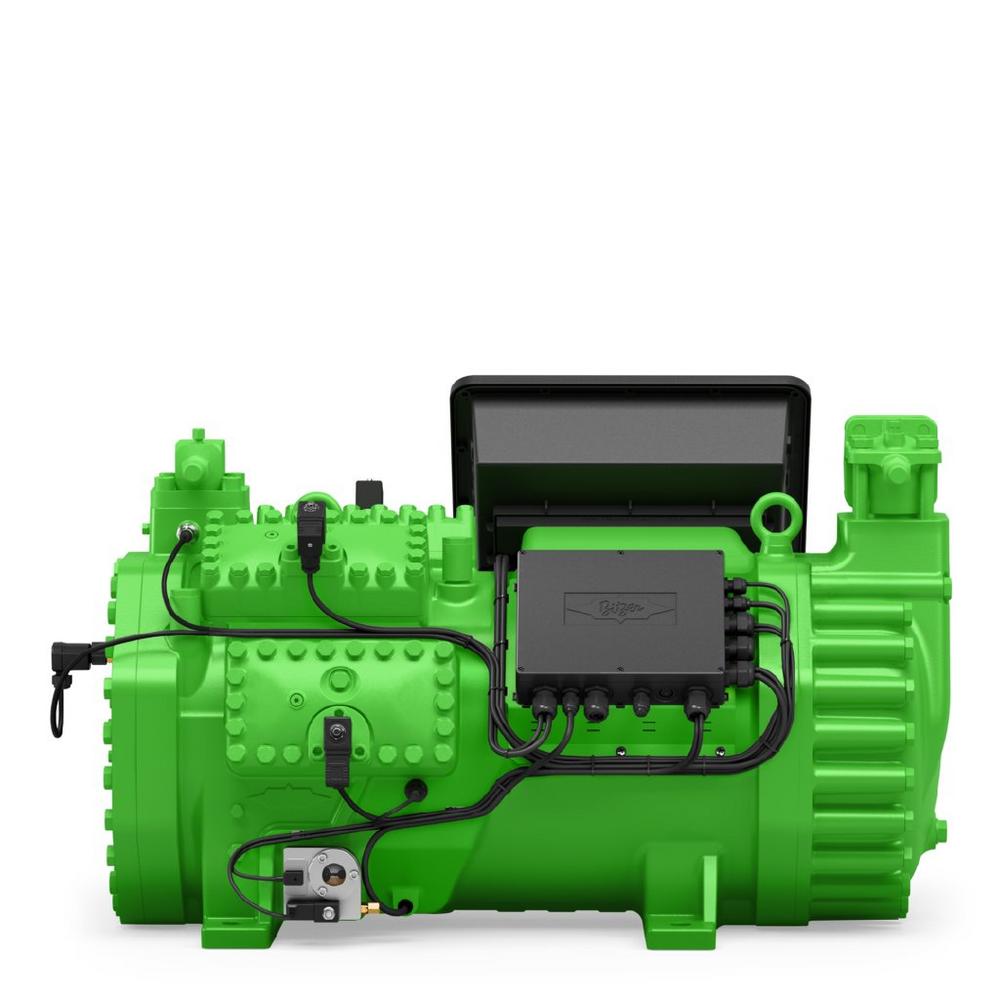

IQ MODULE CM-RC-02 – efficiency booster for new and existing systems

Focusing on energy efficiency, the new generation of the IQ MODULE CM-RC-02 will be one of the BITZER product highlights at Chillventa 2024. It has been a standard feature of ECOLINE reciprocating compressors of the C3 series and higher since the beginning of the year and lays the foundation for even higher efficiency in compressor operation and increased availability. In addition, intelligent functions such as monitoring key operating parameters and a user-friendly operating concept simplify compressor installation, commissioning and maintenance. Thanks to extension boards, the IQ MODULE also simplifies connection and operation of VARISTEP capacity control. ‘With the IQ MODULE, we demonstrate that it is possible to improve energy efficiency without increasing complexity. The IQ MODULE was developed to simplify everyday operations for installers and contractors,’ says Rainer Große-Kracht, Vice-Chairman of the Management Board and Chief Technology Officer of BITZER. There are special performance kits available for retrofitting existing compressors (see product profile). Thanks to the IQ MODULE, VARISTEP capacity control can also be retrofitted at any time to improve efficiency.

Further information about BITZER at Chillventa, including the presentation schedule, is available at https://www.bitzer.de/gb/en/2024_chillventa.jsp

As an independent specialist for refrigeration, air conditioning and heat pump technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always striving for the highest possible energy efficiency and quality. BITZER is represented all over the world with 75 sites in 40 countries, including its sales companies and production facilities. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2023, more than 4,300 employees generated a turnover of €1.01 billion; expenditure for research and development totalled €61 million.

www.bitzer.de

BITZER Kühlmaschinenbau GmbH

Peter-Schaufler-Platz 1

71065 Sindelfingen

Telefon: +49 7031 932-0

Telefax: +49 7031 932-147

http://www.bitzer.de

Head of Corporate Communications and Marketing Content

Telefon: +49 (7031) 932-4327

Fax: +49 (7031) 932543-70

E-Mail: stefanie.holst@bitzer.de

![]()