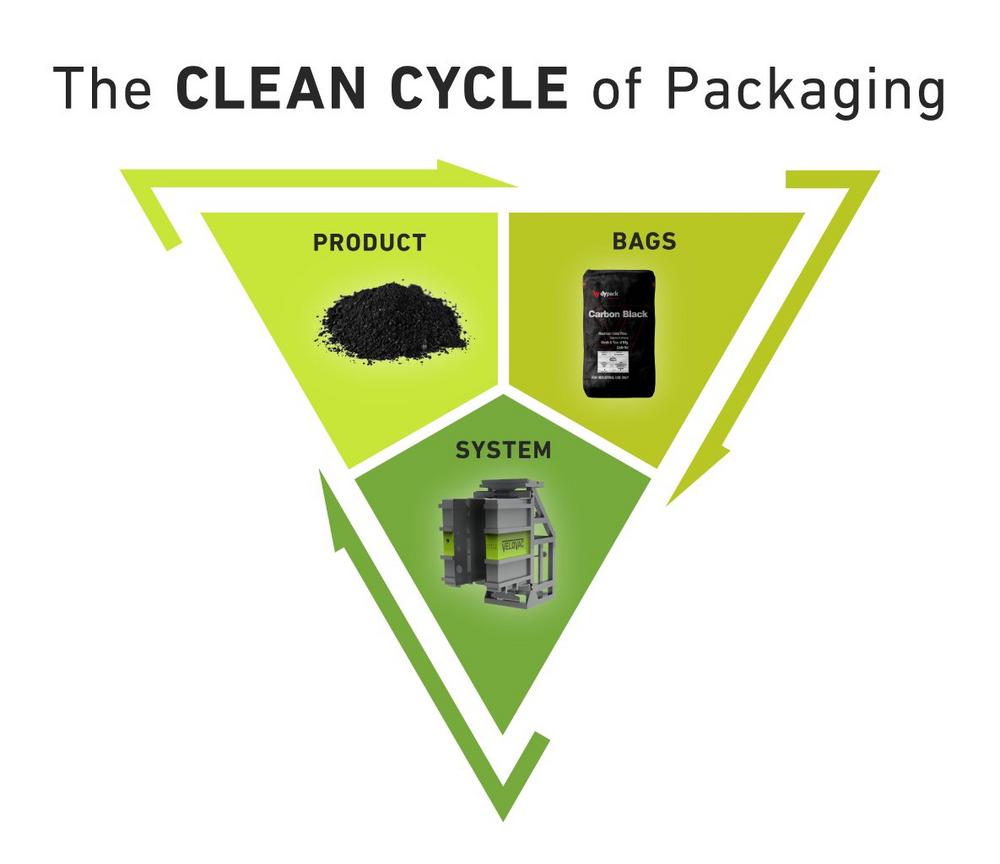

The coordinated components, consisting of the GREIF-VELOX VeloVac vacuum packer and the SafeDyVac bag design, offer manufacturers, such as the customer Birla Carbon, significant advantages: transport and logistics costs are reduced by up to 75 percent, CO2 emissions are minimized, and both product and employees are protected through a dust-free process. Additionally, the high compaction of the product reduces transport volume and increases the stability of the packaging.

Innovative bag design in cooperation with dy-pack

A particular highlight of the CLEAN CYCLE is the innovative bag design, developed in collaboration with the renowned paper bag manufacturer dy-pack Verpackungen Gustav Dyckerhoff GmbH. The SafeDyVac designs are tailored to the needs of the Carbon Black industry and feature an effective moisture barrier system, ensuring reliable protection of the product. Additionally, the innovative construction prevents abrasion damage and optimizes space utilization during transport.

More production efficiency and strengthening of brand reputation

"With the CLEAN CYCLE of Packaging, we offer a tailored solution that not only enhances production efficiency but also strengthens our customers‘ brand reputation through clean and efficient packaging solutions," says Sebastian Pohl, Managing Director of GREIF-VELOX. "The white paper provides detailed insights into this packaging innovation, which we have already presented globally at renowned industry fairs such as Carbon Black World, the Carbon Black Summit, and Solids. We are pleased to have been nominated for the Sustainability Award by Sustainable Packaging News."

The white paper is now available on the GREIF-VELOX website. Click here to download: https://www.greif-velox.com/en/company/greif-velox-clean-cycle-of-packaging

You can find the GREIF-VELOX website at: www.greif-velox.com

About GREIF-VELOX Maschinenfabrik GmbH

GREIF-VELOX Maschinenfabrik GmbH (www.greif-velox.com) sets global standards in the packaging machinery sector and is on its way to becoming a technological leader in the industry. The company designs and implements innovative bagging machines and filling systems, always focusing on maximizing efficiency for the customer. GREIF-VELOX has revolutionized the bagging of ultra-light powders with its VeloVac gross vacuum packer. Additionally, the product portfolio includes palletizing robots to offer complete full-line systems. With a focus on customer requirements, the company continually develops new systems and patents that provide long-term solutions to longstanding industry challenges. Throughout its nearly 1,000-year history, GREIF-VELOX has consistently demonstrated its three core values: efficiency, innovation, and reliability (EIR). Today, GREIF-VELOX Maschinenfabrik GmbH operates globally with more than 150 experts in 89 countries. Since 2024, Sebastian Pohl and Thorsten Köll have been Managing Directors.

GREIF-VELOX Maschinenfabrik GmbH

Kronsforder Landstr. 177

23560 Lübeck

Telefon: +49 (451) 5303-0

Telefax: +49 (451) 5303-233

https://www.greif-velox.com

PR

Telefon: 004945154692373

E-Mail: modrow@agenturhoch3.de

Marketing Manager

Telefon: +49 451 5303 300

E-Mail: b.voges@greif-velox.com

![]()