Accelerate time to market with AI in battery manufacturing

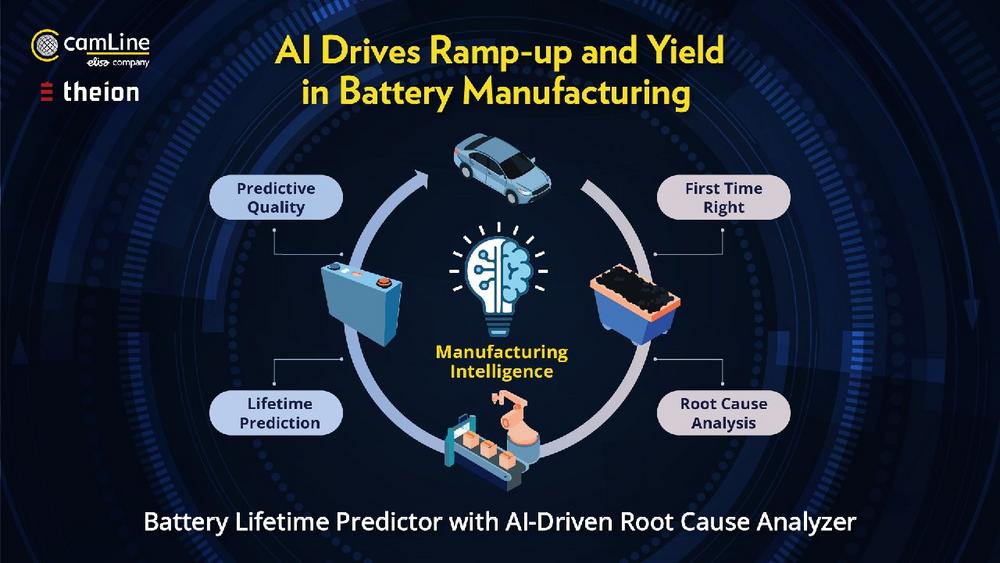

The collaboration brings together camLine’s cutting-edge AI tools, which are the Battery Lifetime Predictor and Root Cause Analyzer, with theion’s innovative approach to sulfur crystal battery technology.

In a recent implementation, camLine’s Battery Lifetime Predictor has reduced theion’s R&D testing times from 42 days to just 15 hours, while maintaining a prediction accuracy of 99.8%. Additionally, AI-Driven Root Cause Analyzer has proven to facilitate early anomaly detection in the production process, enabling faster corrective actions and reducing downtime. This breakthrough allows theion to greatly accelerate its development cycles.

"As a key player in the battery industry, I am proud that our AI-driven solutions have effectively met the needs of theion, reducing their testing times by an impressive 98%. This significant improvement enhances their overall production efficiency in battery manufacturing, allowing them to stay competitive as a leader in the industry," said Mirčo Krsteski, Key Account Manager of camLine.

“After comparing different AI tool solutions for our development process, we identified camLine as a powerful partner that will save us a lot of time while maintaining high quality,” said Martin Schaupp, CTO of theion.

A comprehensive MES solution for scaling production

The partnership also aims to scale solid-state battery production from lab-scale R&D to full-scale manufacturing. camLine’s AI-powered MES suite provides theion with real-time data collection with an efficient track and trace, predictive analytics, and automated decision-making capabilities, ensuring a seamless transition to mass production.

About theion GmbH

Headquartered in Berlin, Germany, theion develops sulfur crystal batteries for mobile and stationary applications. By using sulfur, theion targets to store up to 3x more energy in its batteries compared to today’s generations of batteries. The range of electric cars could exceed 1,000 km, and electric flights would become economically viable. theion’s proprietary production processes are very cost-and energy-efficient, complementing the idea of creating a highly sustainable battery affordable for everyone.

camLine has been recognized as a valued IT solution partner for high-tech manufacturing over the past 35 years. Industry automation systems are based on MES/MOM modules. Numerous implementations can be found in semiconductors, electronics, automotives, solar, batteries, medical devices, and renewable energies across Europe, North America, and APAC. In addition to service domains on quality assurance, process integrity, production logistics, OEE, monitoring and reporting, camLine’s solutions feature the orchestration of shop floor activities among different communication layers. As part of Elisa IndustrIQ, AI and machine learning (AI/ML) techniques are integrated in statistical methods to foster optimal engineering analysis and defect control.

camLine

Fraunhoferring 9

85238 Petershausen

Telefon: +49 (8137) 935-0

http://www.camline.com

CTO

E-Mail: info@theion.de

Director, Communications

Telefon: +44 7766 561661

E-Mail: johanna.jokinen@elisa.com

Key Account Manager

E-Mail: mirco.krsteski@camline.com

![]()